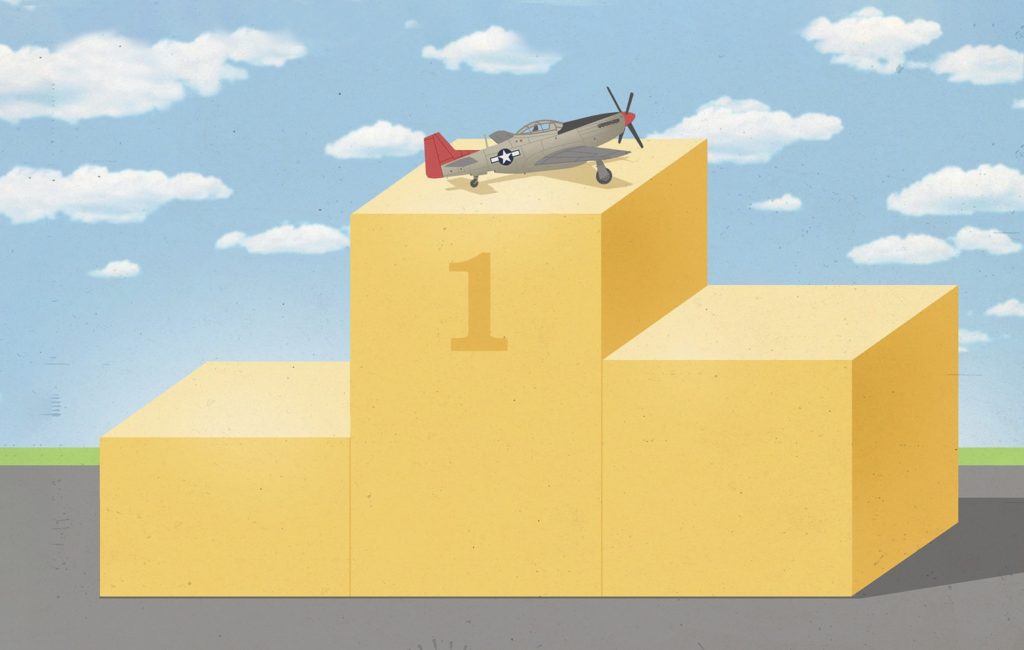

By near universal agreement among friends and foes alike, the North American P-51 Mustang was the best all-around fighter of World War II. Although others might have flown faster, farther, higher or been more nimble, none combined so many outstanding performance aspects in a single airplane.

The story of how the P-51, originally conceived to satisfy a Royal Air Force requirement, was transformed from a good plane to a great one when the British substituted a Rolls-Royce Merlin for its original Allison engine has become integral with the Mustang legend, and gives the impression that everything in that serendipitous matchup fell quickly and easily into place. The Americans who first flew the Merlin-engine P-51B into battle, however, found its introduction to combat nowhere near as trouble-free as posterity might have us believe.

One of those Americans who piloted P-51Bs with the legendary “Pioneer Mustang Group,” Felix Michael Rogers joined the U.S. Army Reserves on April 17, 1942, transferring into the Army Air Forces as an aviation cadet on August 20. After training, he got his pilot’s rating and officer’s commission in Yuma, Ariz., on May 20, 1943.

On June 2, 2nd Lt. Rogers was assigned to the 354th Fighter Group, the first USAAF unit in Britain to operate the Merlin-powered Mustang. Based at Boxted airfield as part of the tactically oriented Ninth Air Force, the 354th also provided escort for strategic bombers of the Eighth Air Force, laying the groundwork for th’e introduction of Mustang units into the Eighth. As Rogers recounts below, his group’s pioneering work was often frustrating and problematic, not to mention inherently dangerous.

Much has been written about the 354th Fighter Group, better known as the Pioneer Mustang Group, and its awesome record in the European Theater of Operations during World War II. Most of these stories speak to the seeming ease with which the newly introduced P-51B swiftly overcame the Luftwaffe’s Messerschmitt Me-109s and Focke-Wulf Fw-190s, trumping the enemy pilots’ combat experience. Yet serious problems accompanied the introduction of this aircraft that severely restricted its effectiveness in the short run.

The need for a long-range fighter to escort the B-17 Flying Fortresses and B-24 Liberators in their penetration of German airspace during daylight precision bombing had been reinforced by the heavy losses incurred in 1943. The British, buyers of the Allison-powered P-51A, suggested the probable solution. The P-51A had originally utilized the American engine to take the pressure off the Rolls-Royce Merlin production line. At this juncture, the Detroit-based Packard Motor Car Company was building the Merlin under license. Its higher horsepower and greater torque compared to the Allison, plus the addition of a supercharger, required a four-bladed propeller.

A full-court press by all concerned put the new Merlin-powered Mustangs into England almost coincidentally with the arrival of the 354th. The decision was made to equip this inexperienced group with the aircraft. These first P-51Bs were then assigned to the Ninth Air Force, but put under the operational control of VIII Fighter Command.

Whatever the rationale for the new arrangement, it was serendipitous. The 354th had two groups of pilots in the main. One was from the flying school class of the fall of 1942, and the other came from the class of May 1943. The leadership was made up of prewar fighter pilots with extensive flying experience plus a few with combat experience, including one from the American Volunteer Group in China, aka Flying Tigers. The average fighter time per pilot was about 400 hours, and the group already had an impressive safety record. From May of that year, it trained as a unit, with designated flight and squadron leaders.

I arrived that same month and was assigned to the 353rd Squadron. My first commanding officer was Major Owen Seaman; the operations officer was 1st Lt. Jack T. Bradley. Major Seaman set an example as the model officer to follow, while Bradley and the flight commanders made us feel unbeatable. The result was that we were eager, ready and enormously confident.

On December 1, 24 P-51Bs of the 354th took off on their first combat mission, a sweep over Belgium and the Pas de Calais led by Lt. Col. Donald Blakeslee, CO of the Eighth Air Force’s 4th Fighter Group. Blakeslee, a former Eagle Squadron Spitfire pilot who was thoroughly disenchanted with the 4th Group’s big Republic P-47 Thunderbolts, liked the Mustang and the Rolls-Royce Merlin that powered the Spit. As a result, he pressed for Mustangs to reequip his unit. In subsequent missions, however, the 354th began to experience disturbing problems.

The group’s efforts to achieve operational readiness with the P-51Bs were severely hampered by training issues, equipment concerns and mechanical problems. Since the aircraft dribbled in to Boxted and were thus unavailable for training, the junior birdmen checked out in P-51As. I got two hours in a Royal Canadian Air Force bird and then two landings in a P-51B before my first B-17 escort mission, to Kiel, Germany.

Our most serious problems from the outset were engine-related. Although the first 40 to 50 aircraft were delivered fairly rapidly, they went to the USAAF depot at Burtonwood, also in the Liverpool area. Burtonwood was faced with the need, as were we in the 354th, to get not only our engine tools from the RAF, but also engine dollies and other handling equipment used in engine changes. To illustrate the impact on numbers of operationally ready aircraft, our engine change time at Boxted initially was 36 hours with six men engaged. In contrast, by August 4, 1944, at Gael, five men could change an engine in six hours. It seems some months were lost before a standard engine change routine was established.

The ground crews were also charged with making the numerous modifications required in the first P-51Bs and Cs. Very early in the delivery cycle, for instance, the 85-gallon internal fuel bags were installed at Burtonwood. Another delaying factor was the need to change installed equipment that was not useful at the higher altitudes and longer durations of the escort missions flown by P-51Bs. Insufficient oxygen (which may have been the cause of death in at least two of our losses) indicated the need for the immediate addition of extra oxygen capacity and new demand systems.

I recall a cryptic conversation between Brig. Gen. Elwood P. Quesada, commander of IX Fighter Command, and our group commander, Colonel Kenneth R. Martin, in which the colonel gave the general a two-week time frame for “operational readiness.” Given that commitment, the availability of the aircraft could have been markedly better. The details of that conversation are lost to history, but did they mean three squadrons of 16 aircraft or three flights of four aircraft? The former in practice would have called for 48 aircraft and six spares—but we hadn’t even received 54 aircraft prior to our first escort mission!

The slow rate of delivery was aggravated further by battle damage. The tempo of operations rose rapidly on the Continent and was a serious drain on our maintenance and service staff.

I must pause here to pay tribute to the can-do attitude, talent and dedication of our ground crews. It seemed to me that my aircraft, dubbed Beantown Banshee, was always ready thanks to Staff Sgt. Harry Phillips, my crew chief.

One of the most serious problems we experienced in the early days was engine failure on takeoff or in flight. The poor visibility over the long nose forced a zigzag taxi, with a corresponding low speed on the engine. This fouled the plugs and caused many takeoffs to be aborted. The American plugs were inferior, so we used British LE40 plugs that were platinum tipped and relatively expensive. Upping the throttle settings on our individual aircraft also shortened plug life.

For engine failure in flight, there were no preferred ditching instructions or cautions, and I don’t recall the preferred method of egress for bailing out. On December 20, we lost our first squadron CO, Major Seaman, when his engine failed over the Channel. Seaman had already voiced concern over bailout because he was very tall and lanky. On that particular flight, he had plenty of altitude, but he chose to ditch. When the Mustang’s big air scoop hit the water, the aircraft nosed over and went straight down. Much later the ditching instructions specified a skip-stone technique with a dipped wing.

The full litany of engine problems is better understood from the history of the 326th Service Group, which contrasted the faults of the Packard-built Merlin with the English-built Rolls-Royce engine. The maintenance problems were monumental. Keeping these aircraft flying was a truly remarkable feat, especially considering they were totally unfamiliar to all the service units, which were equipped with tools that had been designed for P-47 support. Shop equipment, dollies and propeller repair equipment had to be designed and built on the spot.

To the benefit of P-51 groups to come, the workarounds developed by our service personnel were passed on to arriving groups, who could begin maintenance using the proper tools. All credit goes to the 354th maintenance officers and men and the service units, such as the heavy-maintenance group that was co-located with us.

Once the aircraft maintenance issues were in hand, attention turned to what became the other major problem: In the P-51B and C series, the guns did not function properly! From an operational viewpoint the problem became very real when Glenn Eagleston attempted to finish off the first enemy aircraft for the group. After a valiant struggle, he was left with no guns on his final pass. The result was no score for Eagleston, who would become the 354th’s top ace.

The seriousness of the problem was confirmed by Colonel Martin, who was making a zero deflection run on an Me-109 when all his guns quit. The problem came to the fore when Major James Howard, CO of the 356th Fighter Squadron, filed his report on the air battle of January 11, 1944, in which he made a “one-man air force” of himself, shooting down three enemy planes and damaging a fourth, to earn the only Medal of Honor given to a fighter pilot in the European theater during World War II. In his official Tactical Commander’s Report, Howard stated: “…in the majority of cases, after a few bursts from our guns, two or three would jam, leaving only one. Many more e/a [enemy aircraft] would have been destroyed if all of the guns had been functioning properly. The large number of probables and damaged is a clear indication of this condition.”

Speaking personally, I never had an encounter with fully functioning guns in my Beantown Banshee. I did have some beautiful gun camera pictures showing the slewing effect with one outboard gun firing API (armor piercing incendiary), also mentioned in an Eagleston report. Several pilots recounted that the jamming came after “violent maneuvering,” but Bob Weldon of the 356th Fighter Squadron and I both experienced failure after 3 or 4G coordinated turns.

I recall that shortly after we began operations from Boxted, an officer on a fact-finding mission for the Project Office at Wright Field assembled the group pilots in the officers’ club and asked them what they could recommend as improvements on the P-51B. I told him the guns didn’t work. His response made me question the real purpose of his mission. “If you had paid attention in gunnery school, Lieutenant,” he retorted, “you would only need one gun to shoot down an enemy aircraft”!

It’s hard for me to believe, even now, that the gun installation had ever been tested in flight. The addition of small electrically controlled motors helped some, but the problem was not fully corrected until the introduction of the P-51D. Perhaps one of the reasons this situation has never been fully disclosed in the annals of WWII is that many of the Eighth Air Force P-51 pilots only flew later models.

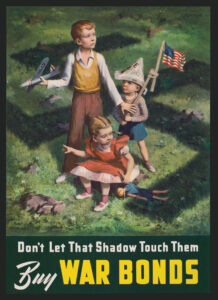

In spite of the difficulties with the guns, the score of the Pioneer Mustang Group was by early 1944 already astonishing. But as if training concerns, equipment issues and mechanical problems weren’t enough, we also had to contend with lagging aircraft recognition expertise. The advent of an entirely new single-engine fighter in the theater came as a surprise to Allied bomber crews and fighter pilots alike. We were thus instructed at the outset, in the fall of 1943, to go to various bomber and fighter bases of the Eighth Air Force and show them what a P-51 looked like, stressing its differences from the Me-109. These included the lack of a tail wheel, contrasting with older models of the 109.

More Mustangs!

Despite our efforts to improve aircraft recognition, there were many instances of friendly fire, mostly from P-47s. The record shows it began early, and I believe either Colonel Martin or then-Lieutenant Eagleston was the first to suffer. In Martin’s case it deprived him of an almost sure victory. Later Captain Eagleston, with his longtime wingman, Ed Regis, was actually shot down by a P-47, bailing out over East Anglia. This went on for six months and continued even when P-51D models, with their Perspex canopies, were the most common fighters on escort missions.

On December 13, 1943, during my first escort mission to Kiel, my Mustang was hit by a top turret gunner on a B-17. I immediately began worrying about potential loss of fuel. The P-51 was the first aircraft with self-sealing tanks that most of us had flown, and we were skeptical about their effectiveness. To my great relief, that experience removed all my doubts about those tanks. By the end of the two-hour flight—the long way back over the Channel—we could barely measure the loss of avgas.

Thereafter, there were a number of incidents of friendly fire from bombers, but many happened when we followed an enemy aircraft too closely, aggressively flying through Fortress or Liberator formations. Generally the B-26 Marauders and A-20 Havocs that we escorted were not subject to aerial attack.

Fuel became less of a problem when an 85-gallon tank was installed behind the cockpit. This was a mixed blessing because it resulted in a shifting center of gravity. In a tight turn, the stick would begin to travel toward your belly of its own volition. If you didn’t stop it at the onset, you’d end up in a spin. Problems also occurred at high speeds with “porpoising.” Baffles were added to overcome this. We learned to burn off at least 20 gallons before going on to the wing tanks. Thus we lost about 20 percent of the potential fuel increase.

Another small change, but a welcome one, was effected when the Service Group procured and installed the British-designed Malcolm hood for the B and C models. Cockpit visibility improved immensely.

When the D model arrived, we noted that the tail had been strengthened, the fabric-covered rudder and elevators had been replaced by aluminum and the firepower had been increased to six guns. Questions had been raised about the early Mustang tail’s ability to withstand high-speed dives. The loss of several aircraft, most notably that of Bill Dehon, who spent four months evading capture behind German lines after his tail assembly failed at extreme speeds on May 11, 1944, seemed to indicate to us that preproduction testing had not included terminal velocity dives.

The USAAF’s success in overcoming the initial problems with the P-51B Mustang involved dedicated professionals at every level. What happened to the P-51B is an example of the synergism resulting from the interplay of design, production maintenance, logistics, testing and combat feedback that sharpened the point of the sword. I cannot conclude without again expressing my debt to our service troops for their superb efforts. All the pilots of the 354th echo this.

When he left the group in October 1944, Major Rogers was a squadron commander with seven victories to his credit, as well as the Distinguished Service Medal with three clusters, the Silver Star, the Distinguished Flying Cross with one cluster, the Legion of Merit with one cluster, a Bronze Star and the Air Medal with 20 clusters. He went on to retire from the U.S. Air Force as a four-star general on February 1, 1978.

General F. Michael Rogers, now 89, lives in Santa Barbara, Calif. Jon Guttman is Aviation History’s research director. Further reading: The Pioneer Mustang Group: The 354th Fighter Group in World War II, by Steve Blake; P-51 Mustang vs Fw 190: Europe 1943-45, by Martin Bowman; and 354th Fighter Group, by William N. Hess.