Did an obscure German welder in Anthony Fokker’s employ, rather than the Dutch aviation pioneer himself, design the world’s first truly modern wing?

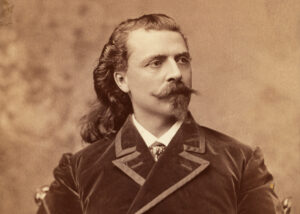

Historians have long disagreed about Anthony Fokker’s role in the design of his firm’s airplanes. In his ghost-written autobiography Flying Dutchman, an entertaining but transparently self-promoting work, Fokker, who was born of Dutch parents in Java but achieved his fame as an airplane builder in Germany, portrays himself not only as the CEO of his firm but also as its chief designer and test pilot. About his skill as a pilot there is little dispute, and there is ample evidence of his business acumen. About his engineering credentials there is more doubt.

It’s striking that Fokker’s autobiography seldom touches upon design issues, even though he must have dealt with a lot of interesting ones. The only technical subject he dwells on at any length is his apparatus for synchronizing the firing of a machine gun with the rotation of a propeller. He barely mentions the evolution of his ideas about airplanes and aerodynamics, which would be of far greater interest to us today.

Airplane design in World War I involved a good deal of guesswork and improvisation. There was some contact between academicians, who sought mathematical ways of understanding fluid flows and predicting their behavior in the abstract, and aircraft manufacturers, who angled for lucrative contracts from the warring governments, but it was neither extensive nor systematic. Their concerns were quite different. Designers relied in their daily work upon experience, intuition and a mix of rumor and report in which the true was not yet clearly distinguishable from the false. They did not require a deep knowledge of aerodynamic theory; in fact, most seem to have made do with hardly any theory at all. Unfortunately, they did not take the trouble to record all their inspirations and missteps.

Thus it is impossible now to know exactly what Fokker designed, what he caused to be designed and what he had little or nothing to do with. Fokker’s most thorough biographer, A.R. Weyl, whose Fokker: The Creative Years simmers with a visceral dislike of its subject, credited a relatively obscure individual, Reinhold Platz, who started out at the Fokker company as a welder but eventually headed its experimental shop, with the design of every Fokker airplane from mid-1916 onward. To Weyl, Fokker was less an aeronautical engineer than an ambitious and not very scrupulous businessman. But another historian, Peter Grosz, who like Weyl had interviewed Platz and who came into possession of Weyl’s archive after the latter’s death, rejected the idea that Platz was the true creative genius, restoring that role to Fokker. To the extent that online prominence reflects reality, however, Platz, who died in 1966, is again in the ascendant; Wikipedia attributes all later Fokker designs to him.

The disagreement between the Fokker and Platz schools hinges to some extent on what you take “design” to mean. The manufacture of airplanes, then as now, had a large paint-by-numbers component. Once a broad configuration had been decided upon, the structural and mechanical details, which within each firm varied little from model to model, could be filled in by specialists and even by the workmen on the shop floor. So similar in most respects were successive designs from a given firm that it is often difficult to say what is a new airplane and what is a new version of an old one. Fokker’s company produced a great many prototypes, including some misguided ones such as the five-winged V8. But failure is an orphan, and it is impossible today to know the sources of, or reasons for, most of the company’s design ideas.

Aerodynamics, to the extent that it was understood in 1915, and structural engineering are not such abstruse subjects that an intelligent person such as Fokker could not pick up a good understanding of them from daily exposure. Whatever may have been his personal faults, neither they nor a lack of formal training would have kept Fokker from becoming a skilled aeronautical engineer if he had chosen that path.

Fascinated by aircraft as a teenager, Fokker experimented with models and developed his own notions about de- sign. His career as a builder began when he was 20 and attending a trade school in Germany. There he helped build a couple of airplanes and began his career as a test pilot.

Experienced constructor and professional engineer Jacob Gödecker helped Fokker produce his first noteworthy airplane, the Spin— Dutch for spider—in 1910. We don’t know which man should be credited with which of its characteristics. Like many of its contemporaries, the Spin had a wire-braced wing consisting of a single layer of cloth sewn to a flexible bamboo frame. Its horizontal tail surface, long and narrow like the tail feathers of a bird, cannot have been very effective, and— birdlike, again—it had no vertical stabilizer at all. Nevertheless, the Spin was sufficiently successful that a number of increasingly streamlined and robust versions were built, and some were used for training military pilots.

A couple of years later Fokker, now running a combined workshop and flying school and supported by loans from wealthy relatives, designed a new type influenced by (Weyl would say “copied from”) a French Morane-Saulnier midwing monoplane. Fitted with the synchronized gun, this Eindecker—the name simply means monoplane—became the “Fokker scourge” of 1915. The Eindecker’s wing, unlike that of the Spin, was skinned on both upper and lower surfaces, but its section was very thin. Roll control depended on twisting, or “warping,” the wings with movable bracing wires, and a thin wing was easier to twist.

Not all designers were of the same mind as Fokker. Wing-warping, which had been used by many early experimenters, including the Wrights, was on the way out, replaced by various arrangements of hinged ailerons. But a more fundamentally important difference involved internal versus external bracing.

Although a number of early designs were wire-braced monoplanes, the biplane arrangement eventually prevailed because, in addition to being strong, stiff and light, it provided a lot of lifting surface in a compact package. But exposed struts and wires produced aerodynamic drag that was out of proportion to their size.

A few designers, notably Hugo Junkers, saw the cantilever wing, which required no external bracing, as a superior solution. The remarkably prescient Junkers was already building metal-skinned monoplanes while Fokker was manufacturing the comparatively primitive Eindecker. The Junkers and Fokker firms would later be pushed briefly into a shotgun marriage by the Idflieg, the air procurement arm of the German military, but even before their official connection Fokker must have been familiar with Junkers’ ideas about cantilever monoplanes. In the spring of 1916, moreover, National-Flugzeugwerke, a small firm with a workshop located alongside Fokker’s factory at Johannistal airfield in Germany, built and tested an airplane with a wooden cantilever wing developed by previously unknown designer F.D. Hergt.

Another neighbor at Johannistal was Swedish engineer Villehad Forssman, who had some experience in aeronautics (he would later design a huge 10-engine triplane, the so-called Poll Giant, which was abandoned, incomplete and unflown, at the end of the war) and who was an agent for Brüning, a manufacturer of aircraft-quality plywood. Forssman had a good deal of contact with Fokker, and arranged for Brüning to build two sets of plywood wings for a prototype that Fokker intended as a replacement for the Eindecker. In the end that project went nowhere, but the plywood-skinned wing with cantilever spars was not forgotten.

Engineers knew perfectly well that the weight of pilot, armament, fuselage and engine could be supported by wooden spars in a cantilever arrangement—that is, without external struts or wires—provided those spars could be more than a couple of inches deep. Most airfoils of the period, however, were not appropriate; they had a thickness of around 1/16th to 1/20th of the chord length and didn’t provide enough internal space for cantilever spars. It was widely assumed that thinner airfoils were inherently more efficient—a belief derived, perhaps, from observing sails or the wings of birds—and this conception continued to prevail at British and French factories throughout the war.

Mathematical theorists of the time did not trouble themselves about bird anatomy or wooden spars, but approached airfoils as variations upon lines and distorted circles. To them, any teardrop-like shape, round in front and tapered to a point in back, had the necessary properties of an airfoil. As early as 1910, Russian Nikolay Zhukovsky had provided a mathematical procedure for generating what we recognize today as excellent airfoil shapes, but at the time nobody knew what an excellent airfoil shape was. To airplane manufacturers, Zhukovsky’s airfoils, if they were aware of them, would have looked no more airworthy than any others—perhaps less, because they were so different from the thin airfoils prevalent at the time. One of the outstanding characteristics of thin airfoils was “undercamber”—the inward-curving shape of the lower surface. Undercamber must have appeared to most eyes to be one of the essential attributes of a successful airfoil. On a thick airfoil, the lower surface may be flat, or both upper and lower surfaces may bulge outward; the curvature or “hump” of the airfoil as a whole is, in effect, buried within, as an imaginary line halfway between the upper and lower surfaces, where only the penetrating eye of a Zhukovsky or a Junkers could discern it.

In June 1916, Martin Kreutzer, the head of F plane and died a few days later of his injuries. After trying and discarding a okker’s experimental shop, crashed a couple of other candidates, Fokker installed Reinhold Platz in his place. Perhaps not coincidentally, a remarkable new prototype, different from any the company had produced before, emerged early in 1917. A biplane, it had a plump, teardrop-shaped fuselage, all-moving empennage surfaces of surprisingly modern appearance and tapered cantilever wings in a sesquiplane arrangement, the lower much smaller than the upper. The internal designation of the type as V1 (the V stood for verspannungslos, or unbraced) suggests that Fokker considered its plywood-skinned cantilever wings its most significant feature.

A photo of the V1 wing prior to covering reveals graceful airfoil sections diminishing in thickness from root to tip. To a modern eye these airfoils appear remarkably sophisticated, and almost as startling in the context of the earthworm-like profiles favored by other manufacturers as a television set would be in a Pompeian mosaic. Where did they come from? This is a mystery. It was not, at any rate, from the Göttingen wind tunnel supervised by Ludwig Prandtl. The eminent theorist tested Fokker’s thick airfoils and added them to his catalogue, but only after they had been used in airplanes.

Fokker may have hoped—as anyone would—for a significant speed improvement from the aerodynamically clean and streamlined design, but it wasn’t there. The V1 was as fast as, but not markedly faster than, other fighters of the time. But it’s very probable that its airfoils yielded lower stalling speeds and a more manageable stall than thinner airfoils would, and consequently conferred improved maneuverability. Superior low-speed performance was the great unintended consequence of the thickness of cantilever wings. It found its first practical application in the Dr.I triplane of “Red Baron” fame, which began life with pure cantilever wings, gaining interplane struts—but no wire bracing— when the fabric-skinned wings of the prototype proved lacking in torsional stiffness.

Although the triplane is one of the iconic fighters of World War I, it in fact served quite briefly, was produced in small numbers and was considered a failure by the Idflieg. Fokker’s greatest success was yet to come. This was the D.VII, a relatively large biplane, originally equipped with a 175-hp Mercedes engine and with thick cantilever wings joined, for torsional stiffness, by outboard N-struts.

Wing torsion—the result of aileron deflection or of the natural tendency of a cambered wing to twist nose-downward—remained a challenge for Fokker. For the sake of light weight, necessary for good climb performance, the accepted method of constructing wings was with a thin plywood skin on the leading edge, where the aerodynamic forces were greatest, and a fabric covering over the rest. The natural torsional stiffness of the plywood box spars and diagonal bracing between ribs was insufficient; interplane Nstruts supplied the necessary reinforcement, but compromised the aerodynamic advantage of the otherwise clean cantilever wings.

Fokker and Platz already knew the solution to this problem from their contacts with Villehad Forssman. Skinning the entire wing with plywood, as had been done on the V1, greatly increases its rigidity, though at a price in added weight. That cost can be offset by the use of a larger engine, which implies more fuel and still greater weight. In 1917, power was hard to come by; light weight was the essential thing, even if it meant accepting the drag of interplane struts.

It was not until 1918 that the advanced structure of the V1 wing found its way into a production fighter. This was Fokker’s E.V (later redesignated D.VIII), which entered service just five months before the November armistice. Nicknamed the “Flying Razor” by Allied pilots because of its single blade-like wing, it was a parasol design with a boxy fuselage, similar to the triplane’s, suspended from the wing on several steel struts. Fokker/Platz must have concluded from the V1 experience that an oval fuselage didn’t gain you anything but admiring stares. The E.V had a distinctly old-fashioned empennage; it was, in fact, a clunky-looking airplane in all respects but one: its wing.

The rest of the airplane may have been pulled off the well-stocked shelves of Fokker’s factory, but it is impossible to overstate the beauty and refinement of that wing, and not to marvel at its having existed less than 15 years after the Wright brothers’ primitive Flyer staggered into the air at Kitty Hawk. Its stressed skin is stiff and smooth; its taper, tip shape, aileron integration and airfoil all strike the eye as perfectly appropriate to a fighter or transport of the 1940s. Reproduced in metal, it would be right at home on an Me-109. A lightplane wing constructed today could hardly improve upon it. It did, in fact, provide the template for postwar Fokker wings, including that of the Trimotor, the first airplane to provide commercial service across the United States.

This remarkable wing represents a sort of perfect storm of good ideas; there is nothing about it that one would change in retrospect. Its features flowed from several sources: Junkers, Forssman, perhaps Hergt and no doubt Fokker himself. But it exhibits a singleness of purpose and a purity of form that suggest the overall control of a single inspired designer. Since it was different from all other Fokker wings, and was plainly descended from the V1 that came into being a few months after the death of Martin Kreutzer, it was most likely mainly the work of Kreutzer’s successor, Reinhold Platz. If this was the case, Platz was a remarkably gifted intuitive aerodynamicist whose contributions have not received the recognition they deserve: He was the first to design a truly modern wing.

L.A.-based aviation writer Peter Garrison is a developer of aircraft design software and the self-taught designer and builder of his own airplane. He wishes to thank Mike Tate, on whose research and writing this account is largely based, for his assistance.

Originally published in the January 2014 issue of Aviation History. To subscribe, click here.