Alesksei N. ”Lesha” Grinchik had only seconds to live. As he bottomed out of a high-speed pass over a Soviet airfield, one of the ailerons inexplicably fluttered off the wing of the MiG I-300 prototype he was flying. Before Grinchik could react, the jet slammed into the ground at over 500 mph, killing him almost instantly. Only a few weeks before, on April 24, 1946, Grinchik, an ace of the “Great Patriotic War” and an experienced test pilot, had been accorded the honor of being the first Soviet citizen to fly the first Soviet jet. An investigation of the crash traced the fault to a cracked compensation lever in the aileron linkage.

Artyom I. Mikoyan, the MiG Design Bureau’s chief builder and a friend of the voluble Grinchik, was distraught over the incident. But he was given precious little time to grieve—within a matter of weeks, Mikoyan was summoned to the Kremlin and ordered by Chairman Josef Stalin himself to have at least 15 of the new jets ready in two months’ time for the October Revolution flyover. The chairman intended to make a visible and dramatic statement to the world: The Soviet Union was not to be trifled with. Ironically, the flyover was canceled due to bad weather.

MiG is undoubtedly one of the world’s best-known aviation acronyms. In the second half of the last century, MiG produced more jet fighter aircraft than most other manufacturers combined, and supplied them to more than 40 air forces all over the globe. But MiG’s first seven years were characterized by limited success in aircraft production and too many dead-end projects. And during the Soviet Union’s Stalinist period, an aircraft design bureau (OKB) that failed to produce often ceased to exist—its designers, engineers and technicians were reallocated to more successful OKBs if they were lucky. Or they might even end up in the Red Army or a Siberian work camp.

The now-famous partnership between Mikoyan and Mikhail I. Gurevich began in late 1939, while both men were still attached to the OKB headed by Nikolai N. Polikarpov. Polikarpov, who was responsible for some of the earliest Soviet aircraft designs, was regarded by his peers as the “king of fighters.” A year before, the Commissariat of the People for Aviation Industry (NKAP) had circulated a directive (Project K) to Polikarpov and other OKB chiefs, pressing for development of new fighter designs to replace those in service with the V-VS (Soviet air force), mainly Polikarpov I-15 biplanes and I-16 monoplanes. While equipping “volunteer brigades” in the Spanish Civil War and Sino-Japanese War, both Polikarpov types had proved woefully deficient against German and Japanese fighters, Germany’s new Messerschmitt Bf-109 in particular. At the time, Mikoyan was employed at the Polikarpov plant as a representative to the V-VS, while Gurevich had recently joined the OKB as a design group leader on Project K.

Mikoyan had been born to humble circumstances in a small Armenian village in 1905. After serving a two-year hitch in the Red Army, in 1931 he was admitted to the Zhukovsky Academy (a school that trained officers for the V-VS), where he demonstrated a talent for aircraft design and production. Upon graduation in 1937, he was sent to the No. 1 Aviakim factory near Moscow, where the Polikarpov OKB was located. In 1939, while Mikoyan was in charge of reorganizing and upgrading the I-153 production line (the I-153 was a retractable-gear derivative of the I-15), his abilities came to the attention of P.A. Vorinin, manager of the Polikarpov plant, and P.V. Demenyev, chief engineer. Besides Mikoyan’s organizational skills and popularity within the NKAP and V-VS, Vorinin and Demenyev were also undoubtedly aware that he had high connections in the Communist Party, namely an older brother, Anastas, who was an important member of Stalin’s Politburo. When the two men were secretly called to meet with Stalin in late 1939 to discuss the leader’s dissatisfaction with progress at the Polikarpov OKB, they suggested the formation of a new experimental design section (OKO) consisting of Polikarpov’s top people, to be headed up not surprisingly by Artyom Mikoyan. After being told to form the OKO, Mikoyan, who was neither an engineer nor a scientist, wisely decided that he needed a deputy who possessed the technical expertise he lacked. He had been favorably impressed by the design group leader on Project K, Gurevich. Then 47, Gurevich, a graduate of the Kharkov Technology Institute, had been involved in the Soviet aircraft industry since 1930. From 1936 to 1938 he spent time at the Douglas Aircraft plant in the United States, working to obtain a license-built version of the DC-3 transport for the USSR, the result of which was the mass-produced Lisunov Li-2.

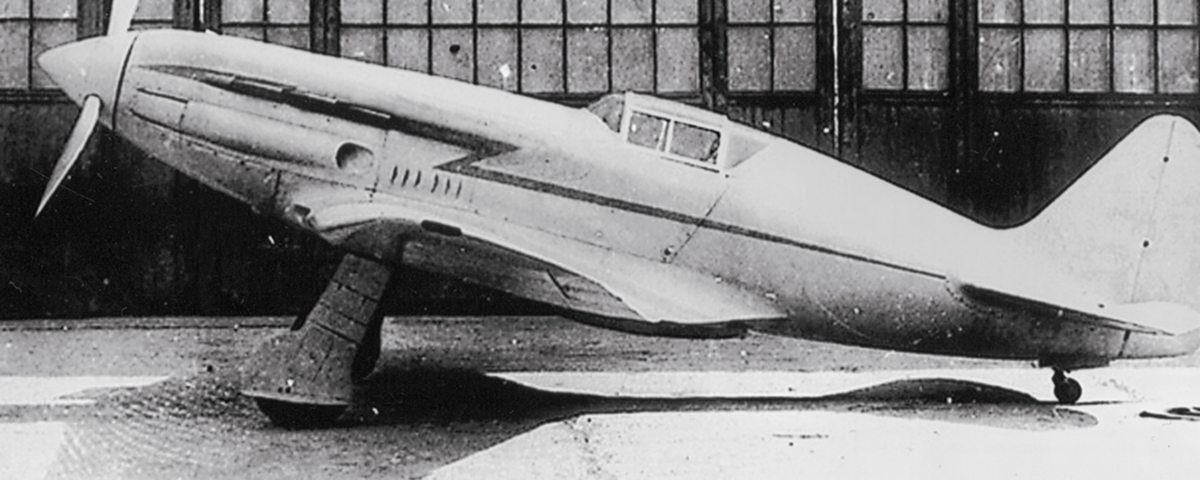

Taking the preliminary work done in Project K, the new OKO began to finalize its design of a monoplane fighter prototype under the designation I-200. It evolved as the smallest possible airframe around the Mikulin AM-37, a liquid-cooled V12 power plant that, with supercharging, was expected to produce 1,380 hp above 16,000 feet. When the AM-37 failed to materialize, the team was forced to use the AM-35, which developed 180 hp less. The structure of the I-200 was conventional, but due to mass-production concerns and the scarcity of metals, some of its major subassemblies—outer wing panels, fuselage aft of the cockpit and empennage—were made of wood. The cockpit, enclosed by a side-hinged canopy, was very basic, including only essential flight and engine instruments and no radio or heater. The landing gear layout featured a main gear that retracted inward into flush wells and a tail wheel that retracted rearward into the fuselage.

The pace of work was so intense—spurred by government pressure and the knowledge that competing OKBs (Lavochkin and Yakovlev) were ahead of them— that the fledgling OKO moved from its first set of production drawings to the first flight of the I-200 prototype in a mere 100 days, on April 5, 1940. The flight trials, which included two more prototypes completed in May and June, respectively, went almost as quickly. The I-200 prototypes were fast (403 mph) and high-flying (39,370 feet), but suffered from deplorable handling qualities. They were dangerously unstable at high angles of attack, with the tendency to stall without warning and enter spins that were almost impossible to recover from. Visibility from the aft-located cockpit was terrible, exacerbating the plane’s treacherous stall characteristics during takeoff and landing.

But the I-200, coming to fruition at a time when the Soviet government was becoming more and more paranoid over the seemingly unstoppable power of the Nazi Reich, became a child of necessity. Thus in September 1940 it was ordered into immediate production as the MiG-1 (Mikoyan and Gurevich Type 1) despite its faults. In fact, only minor modifications were made to production models, including increased radiator capacity, an additional oil cooler and self-sealing fuel tanks. Production versions were armed with two 7.62mm ShKAS machine guns and one 12.7mm UBS machine gun, all housed in the nose. Initial output during the spring of 1941 was marred by constant modifications and numerous accidents, which meant the new fighters reached V-VS units only in small numbers. Pilots serving in these units were reportedly very displeased about exchanging their I-15s, I-153s and I-16s for problematic MiGs.

Meanwhile the OKO worked feverishly to correct the MiG-1’s deficiencies. Improvements to the follow-on Model I-201 included increased wing dihedral, movement of the engine forward, more fuel capacity, a new propeller, armor plate and a radio. But its general flying characteristics were only marginally better, and it was still dangerous in the hands of inexperienced pilots.

In December 1940, the improved type was nonetheless ordered into production as the MiG-3 at the Aviakim factory and began reaching V-VS units at practically the same time as MiG-1s. The actual numbers of MiG-1s and MiG-3s serving with V-VS and air defense (PVO) units at the time of the German invasion of the Soviet Union (Operation Barbarossa) in June 1941 isn’t clear, but we do know that most fighter regiments were still equipped with obsolescent I-15s, I-153s and I-16s. And like hundreds of other Soviet aircraft on the morning of the German attack, most of the MiGs were destroyed on the ground.

In the fall of 1941, the German advance threatened the Aviakim factory. The OKO’s operations were hastily moved to Kuybyshev, on the Volga River (more than 500 miles southeast of Moscow), where production of the MiG-3 was resumed. But when the new plane was introduced into combat, the MiG’s performance proved to be markedly inadequate. The Luftwaffe’s improved Me-109Fs and even newer Focke Wulf Fw-190As were superior in all respects, plus the air war over Soviet front lines was generally being fought below 15,000 feet, placing the MiGs at an even greater disadvantage. A curious telegram was sent out by Chairman Stalin in December 1942—not directly to Mikoyan or the OKO, but to the managers of the two factories in Kuybyshev that built MiG-3s and AM-35 engines. He said: “You are playing a shabby trick on our homeland and on our Red Army….Il-2s are today as essential to our Red Army as are air and bread [the Ilyushin Il-2 Shturmovik was a ground attack aircraft built at the same plant and used the same AM-35A engine]. We need Il-2s, not MiGs….Let this be a last warning to you both. —No. P553 STALIN.”

Not surprisingly, MiG production, after a run of 100 MiG-1s and 3,322 MiG-3s, came to a grinding halt, and the unavailability of AM- 35 engines dictated that production would not be resumed. During the balance of 1942 and 1943, MiGs remaining in operational units were relegated to reconnaissance and night operations as rapidly as they could be replaced with more capable Yak-1s, Yak-7s and La-5s.

Another program that had been started in 1940 as a separate brigade within the MiG OKO was the long-range escort fighter project (DIS) led by P.D. Grushin. The DIS (Project T) was a big twin-engine, single-seat aircraft intended to operate variously as an escort fighter, highspeed reconnaissance plane or light bomber, and incorporating the same liquid-cooled Mikulin engines used in the MiG-1/-3 series. The first flight was made in May 1941 at the Aviakim plant, and testing soon revealed a respectable top speed of 378 mph and a ceiling of 25,425 feet. The prototype, which initially exhibited poor low-speed handling characteristics, was modified to include automatic leading edge slats and slotted landing flaps. The fighter version was designed to be armed with four 7.62mm and two 12.7mm machine guns plus one 23mm cannon. But the relocation of the OKO to Kuybyshev following the German invasion stopped work on Project T before a serious evaluation of the type could be made, and the lack of AM-35 engines put the question of production on hold.

Despite its limited success thus far, in early 1942 the MiG organization was moved back to Moscow and accorded the status of a full-fledged OKB. MiG was already working on a number of projects intended to replace its less than successful MiG-3 and create a production version of the DIS. Significantly, the Central Institute for Aviation Engines (TsIAM) had placed a new type of engine into mass production, the Shvetsov M-82, a 14-cylinder radial rated at 1,400 hp, with more powerful versions expected to follow. In response the OKB quickly modified a MiG-3 airframe to accept the radial engine, but the resulting Model I-210, which flew in January 1942, exhibited worse handling characteristics than the MiG-3 and was 40 mph slower. MiG’s second attempt at a radial installation, the Model I-211, adopted a cowling arrangement similar to that of the La-5, with the supercharger and oil cooler ducting moved to the wing roots. When the plane flew in mid-1943, it was marginally faster but not as maneuverable as the combat-proven La-5. No production resulted.

In early 1942, the OKB also began working to modify a second DIS prototype for installation of M-82 radials. After making its first flight in late 1942, the DIS-IT prototype reached a top speed of 375 mph and a service ceiling of 32,100 feet (note that the DIS-IT was 33 mph faster and could operate 6,000 feet higher than Messerschmitt’s late-war Me-110G and H series). But Soviet disillusionment with the twin-engine fighter concept led to cancellation of the project while flight testing was still underway. New attempts within the OKB to create a successor to the MiG-3 during 1942 and 1943 also proved fruitless. The MiG-3U (U stood for improved; also identified as Models I-230 and I-231), which appeared in early 1943, featured extensive aerodynamic improvements and a lighter, all-metal airframe. But despite the new design’s excellent performance (409 mph) and improved handling, no AM-35A engines were available, and a supply of the alternative AM-39A never materialized— so once again no production resulted.

Other projects begun by the OKB in late 1942 concentrated on creating a single-engine, high-altitude interceptor to deal with Luftwaffe reconnaissance aircraft. The I-220 and I-221 prototypes of 1943 shared little commonality with the MiG-3 except for the use of inline Mikulin engines (a salvaged AM-35A on the I-220 and an experimental AM-39A on the I-221). Both types used a completely new wing planform of greater span and area than the MiG-3, with noticeable leading edge sweepback on the outer panels. The engine on the I-221 was fitted with dual turbosuperchargers, giving it a top speed of 429 mph and an impressive ceiling of 42,650 feet. But as before, the shortage of Mikulin engines kept either type from being placed in production. MiG’s ultimate high-altitude prototypes, the I-222 and I-224, flew in 1944 and are credited with being the first Soviet aircraft to have pressurized cockpits. These planes had truly stratospheric performance, operating as high as 46,200 feet, and while they were only experimental, they still gave MiG’s engineers valuable experience with cockpit pressurization and other aircraft systems designed for operations above 40,000 feet.

The final piston-engine design to come off MiG’s wartime drawing boards was the I-225, which flew in March 1945. While incorporating the improvements learned from the high-altitude program, the smaller-winged I-225 was specifically intended for normal fighter operations at medium altitudes. The 2,000-hp AM-42FB fitted to the second prototype was the most powerful piston engine produced in the USSR up to that time, and the I-225’s 451-mph top speed made it the fastest Soviet propeller-driven fighter of the war. But the capture of German turbojet technology by Soviet forces in the spring of 1945 effectively placed on hold any plans to put new piston-engine types in production.

In fact, the MiG OKB had already designed and flown a fighter powered by a unique piston-ramjet arrangement, and had also completed much of the work on a second fighter design that would use two turbojet engines. Both efforts had commenced in early 1944 after the Soviet Committee for State Defense (GKO) charged all fighter OKBs with the responsibility of developing a jet-propelled fighter aircraft for the USSR. Given the fact that TsIAM had yet to produce a usable turbojet engine, the OKBs faced a daunting task. The MiG OKB approached the problem in two ways: Project N—a fighter designed around the unusual VRDK power plant; and Project F—one designed around two turbojet engines.

Developed in 1943-1944 at TsIAM and known simply as the “booster,” the VRDK was a piston engine driving a conventional propeller and a compressor that fed into a ramjet-type combustion chamber. In boost mode, the VRDK augmented the piston engine, a 1,650-hp Klimov V12, with approximately 660 pounds of static thrust. Project N, the VRDK-powered Model I-250, bore no resemblance to any previous MiG venture and incorporated many of the latest aerodynamic innovations developed by the Central Aero and Hydrodynamics Institute (TsAGI), including a thin laminar flow wing with frise ailerons and slotted flaps. Following mockup approval in late 1944, the GKO and V-VS were sufficiently impressed to give the OKB the go-ahead to construct a prototype as a preproduction model. At last! The prototype made its maiden flight in early March 1945 under piston power only, and five days later, on the third flight, the VRDK was fired. Under VRDK boost, the I-250 reached a maximum speed of 514 mph and an altitude of 39,200 feet—outstanding in comparison with piston-engine fighters of the day. In May, as if to confirm MiG’s success, the GKO canceled Sukhoi’s competing VRDK project and ordered the I-250 into production as the MiG-13. Yet only a small number of MiG-13s were actually produced (some sources say 16 or 17); like its piston-engine I-225 stablemate, the MiG-13 was overshadowed by the USSR’s overnight acquisition of a turbojet engine program during the spring of 1945.

In truth, the I-250 was doomed before it flew. Once it was apparent that Soviet-made jet engines would not be forthcoming any time soon, in early 1945 Stalin instituted a hurried program among the fighter OKBs to plan on using captured German engines months before the fact. Thus when Red Army forces overran the Junkers and BMW factories late that spring, the preliminary design for MiG’s project F, the Model I-300, was well underway.

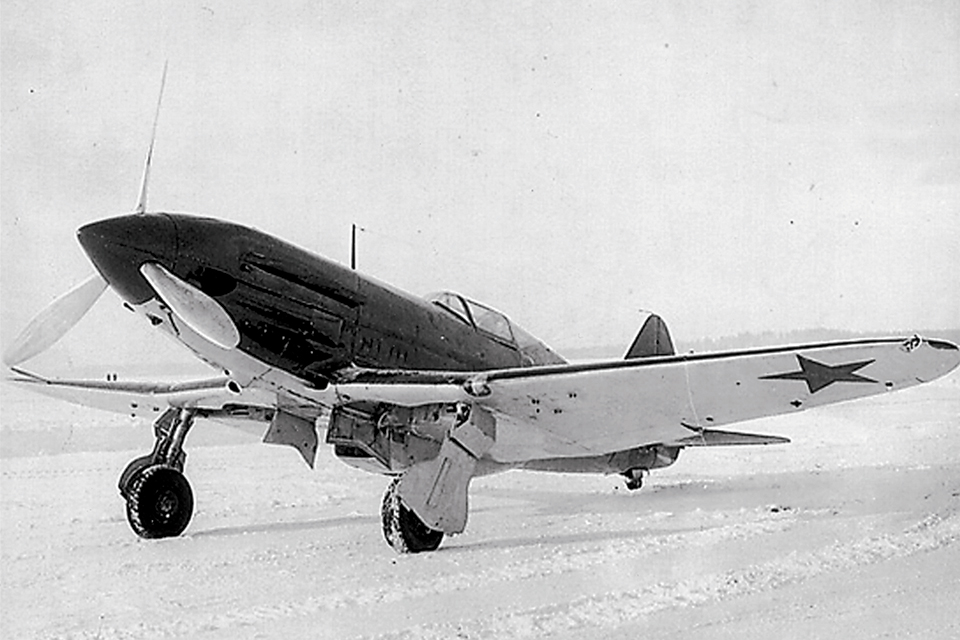

From the beginning, the I-300 had been designed to accommodate two turbojet engines installed in the belly of the fuselage below the midmounted wing. Both Mikoyan and his chief project engineer, A.G. Brunov, believed this configuration would be superior in terms of drag and maneuverability than the wing-mounted engines seen on the Messerschmitt Me-262 and the Gloster Meteor. The wing planform was basically similar to that of the I-250, and the tailplane was set in a high cruciform arrangement to stay clear of exhaust flow. When the captured BMW 003 turbojets allocated to MiG finally arrived in the summer of 1945, the design of the lower fuselage was modified accordingly.

The preliminary design was approved in the fall of 1945 and the mockup in January 1946. The first flight apparently involved some political maneuvering, inasmuch as the Junkers Jumo-powered Yak-15, which sources indicate was ready to fly by the end of 1945, took off on its maiden flight just three hours later. The I-300’s performance was similar to that of other straight-wing jets of the time. Its flying characteristics were good enough that new military pilots could easily learn to fly it. Refinements to the basic design resulted in the improved Model I-301 and mass production of the MiG-9 (given the NATO code name “Fargo”). A two-seat trainer version, the MiG-9UTI, was introduced in mid-1947. But production was halted after only 1,100 planes had been built because by 1948, within the space of just two years, the MiG-9 and all its straight-wing contemporaries were already obsolete.

Two things had happened: In 1946 Great Britain sold 30 Rolls-Royce Nene turbojet engines (5,000 pounds static thrust with water injection) to the USSR, and shortly after that TsAGI, through wind tunnel tests, concluded that a wing sweep of 35 degrees incorporating fences to control traverse stability and airflow breakdown would produce optimal performance in a Nene-powered fighter. As early as February 1947 the MiG OKB began drafting plans for Project S (Model I-310), a midwing fighter designed around TsAGI’s new wing configuration and the Nene engine. After its first flight in December 1947, the I-310 underwent many modifications before being accepted by the V-VS, but the OKB had finally conceived something that was world class: a fighter that could reach 652 mph at sea level (Mach 0.856), was easy to fly, simple to maintain and could be manufactured in huge numbers. The silhouette of the resulting MiG-15 (given the NATO code name “Fagot”) became one of the best known in the world. By the mid-1950s, more than 8,000 MiG-15s in all versions had been produced by the USSR, Czechoslovakia, Poland and Hungary, and even after they were replaced in frontline service within the Soviet Union and Warsaw Pact countries, MiG-15s continued to soldier on in many Third World air forces well into the 1960s.

Originally published in the March 2007 issue of Aviation History. To subscribe, click here.