“Sikorsky was the first to make helicopters practical,” wrote aviation expert C.V. Glines, “but he was preceded in his successes by other scientists and inventors whose failures and discoveries contributed to his ultimate triumph.” Among the most important of those early inventors was Maitland Barkelew Bleecker, who designed, built and successfully flew a helicopter in 1930, nine years before Igor Sikorsky. But just as his invention was taking off, the Great Depression crashed his life’s work.

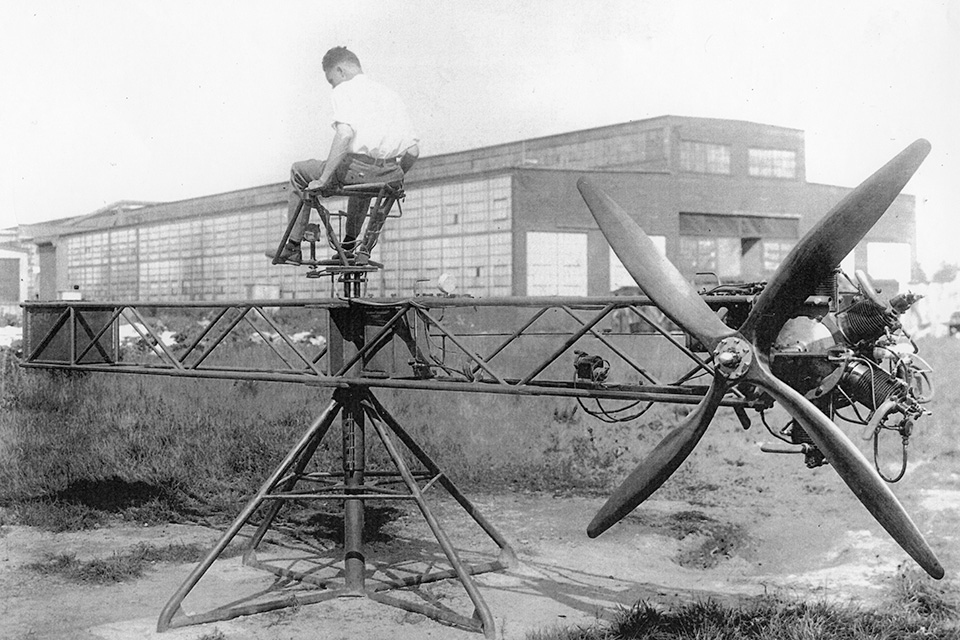

In 1922, when Bleecker was a junior in the University of Michigan’s aeronautics program, Professor Richard Thomas Liddicoat asked him to work with him on a new kind of aircraft that could take off and land vertically, hover in place and move laterally. Bleecker produced most of the construction drawings and designed the propellers. The one-half-scale model of the professor’s helicopter was able to get off the ground, but had no capability for controlled lateral flight because of its fixed rotor blades. The project was, however, the genesis of great ideas in Bleecker’s flying-oriented mind.

Upon graduation in 1924, Bleecker was hired by the National Advisory Committee for Aeronautics (NACA, forerunner of NASA) at Langley Field in Virginia, where he was responsible for testing and troubleshooting aircraft. One day, moments before he was about take off on a test flight in a Curtiss JN-4D “Jenny,” the project manager came running up with a new employee who had never flown. He asked Bleecker if he would delay the test and give up his seat. Bleecker complied, only to watch the plane bank sharply and crash just seconds after takeoff, killing the man who had taken his place.

With that brush with death still fresh in his mind, Bleecker decided to devote himself to developing something new and different enough to convince an aircraft manufacturer to hire him. His mind went back to his days working with Professor Liddicoat on the proto-helicopter. Building on his experience at Michigan, Bleecker developed an innovative helicopter flight control system. On July 7, 1925, he filed a patent application for a helicopter featuring this revolutionary new system.

Bleecker brokered a deal with the Curtiss Aeroplane and Motor Company in Garden City, Long Island, to develop a helicopter prototype, and in January 1926 reported to Curtiss Vice President Theodore P. Wright. Without pay, Bleecker would be given office space and the use of facilities to construct models and testing equipment to bring his helicopter to life. Upon completion, he would submit a report and Curtiss engineers would evaluate his design.

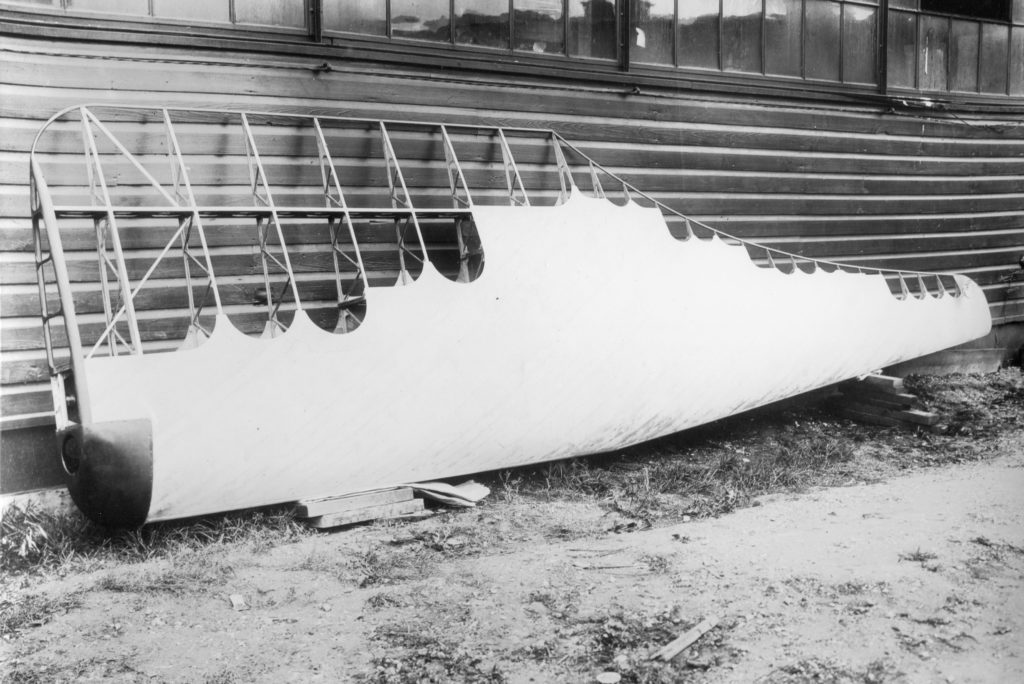

Bleecker had to develop much of the testing equipment, since none existed for the mechanics of this revolutionary form of flight. The process to make the rotor blades was particularly daunting, as it required great precision to produce non-warping blades. The aircraft’s most important design feature, one that had eluded others who had attempted to develop a helicopter, was its intuitive control mechanism. It featured independent collective and cyclic control of the blades, which is so fundamental that it is the standard control system in all helicopters to this day.

The critical component was called the “distributor,” or “wobble plate,” as it is referred to today. It could change the angle of attack of all the rotor blades equally and simultaneously for what is known as collective pitch control. For lateral and longitudinal control, and to generate and hold transitional flight, the rotor blades could be controlled in a cyclic fashion with the aid of “stabovators” extending from the trailing edges that were raised or lowered to adjust rotor pitch. During each 360-degree rotation cycle, a rotor blade’s angle of attack gradually changed from the selected collective angle to a greater or lesser angle, depending on the blade’s position in the cycle, and then returned to the selected angle. These two functions took place independently of each other, with cyclic control via the pilot’s control column and collective functions controlled by a lever alongside the pilot’s seat.

Bleecker’s patent showed, schematically, how to do this, but it didn’t properly claim the concept as his own. As a result, his patent failed to protect him from having Sikorsky use a similar system nine years later.

After several months in the Curtiss shop, Bleecker had a model ready for wind tunnel testing. A total of 44 distinct tests of the design’s aerodynamic properties were run and analyzed. The results were presented on December 20, 1926, for approval to begin full-scale development.

Curtiss finally approved the project in mid-1927. At 24 years old, Bleecker was given a contract as project engineer for managing the design, construction and initial test flights of the full-scale prototype. If it went into production, he would receive royalty payments.

The long, often grueling process began to transform Bleecker’s research and dreams into a viable reality. Four draftsmen were assigned to make subassembly drawings of major components such as the landing gear, fuselage skeleton, control surfaces and rotor blades from three-view scale drawings prepared by Bleecker. As these schematics were generated, they were passed on to the stress department to check safety factors under maximum load conditions. Then the weight section computed the actual weight of the represented part, keeping a running account to make sure they weren’t exceeding initial estimates.

Bleecker encountered a major hurdle with the installation of the 9-cylinder, 425-hp Pratt & Whitney Wasp air-cooled radial engine that drove a single propeller on the leading edge of each rotor blade. Since the engine was to be mounted in a vertical rather than traditional horizontal position, the carburetor and oiling and cooling systems would need to be modified. At first Pratt & Whitney officials refused to sell him one of their engines when they were told how it was to be used. They were sure it would fail and didn’t want the bad publicity. Bleecker had to sign a waiver removing them from any liability. He got the engine.

The problem of cooling a vertically mounted engine intended to operate horizontally was resolved by fabricating cooling baffles that fit between adjacent cylinders, channeling the horizontal airflow into the cylinder fins and down to the cylinder walls. To create the necessary airflow during hovering, a small Hamilton Standard propeller was fitted to the engine’s nose to act as a cooling fan close to the cylinders. Oiling issues were resolved by dismantling the engine and drilling holes in any diaphragm or pocket that might prevent the oil from collecting in the lowest part of the now-vertical crankcase. The oil was then circulated by the normal pressure oil feed pump. The carburetor was simply mounted using a 90-degree aluminum elbow so that it was in the normal horizontal position.

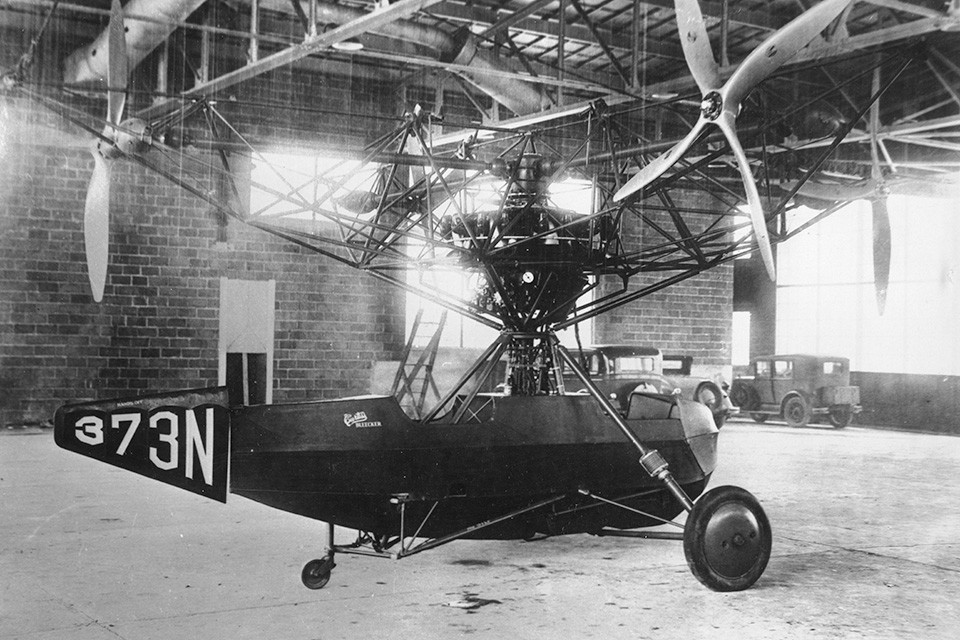

After three arduous years, the helicopter was taking shape and becoming an exciting reality. For security reasons during flight testing, the team moved the craft away from prying eyes to Curtiss’ nearby Valley Stream airfield.

The moment of truth came in the newly assigned giant hangar. With his stomach in a knot, Bleecker fired up the Wasp engine and gradually increased the rotor RPM. He watched as the rubber doughnuts in the landing gear struts lost their squashed shape and, rather quickly, the polished tube of the hydraulic shock-absorber piston began to show. All movement was in proper phase with the control stick, and while Bleecker didn’t become totally airborne, he could raise any one of the three wheels off the ground individually. He breathed a quiet “Thank you, God.”

Unfortunately, as the team prepared to begin flight testing, the Great Depression was catching up to the Curtiss Company. The Garden City plant was closed, and the engineering staff and aircraft production were moved to Buffalo, N.Y. The company photographer went with them, at a most inopportune time, just as test flights were about to begin at Valley Stream. The move and consequent need for long-distance communication would complicate things at a very critical stage.

Kodak had just introduced its 16mm movie camera, and Bleecker’s father thoughtfully gave him one. Bleecker taught Al Blashiell, his invaluable mechanic, how to use the camera so that they could film every flight.

Testing got underway in earnest in June 1929, with Bleecker initially serving as pilot. The early flight tests were made within the huge hangar, where hovering up to 20 feet high was possible. Test hops focused on manipulating the controls to see how the machine reacted to aerodynamic forces. Unbalanced aerodynamic conditions that were encountered were resolved by locating stops in the rotor blades and control surfaces.

One surprise was that, when fully airborne, it was very difficult to keep the helicopter’s fuselage from rotating. That problem was remedied by installing a narrow brake drum around the spindle and connecting it with a brake band to the right rudder pedal, allowing the pilot to control rotation. By manipulating the two rudder pedals, which controlled the tail surface’s exposure to rotor downdraft, the fuselage could then be turned in any direction desired.

Many takeoffs, climbs and flights in various directions were made, as well as landings with the power shut off. During one flight, Blashiell lowered the camera and Bleecker saw him frantically waving him down. The cooling propeller had stopped turning. It turned out that the teeth had sheared off the small double gear that connected the propeller to the engine crankshaft. Bleecker asked Curtiss to make a new one out of a higher strength steel, and testing resumed when the new gear arrived from Buffalo.

Recommended for you

At last, on June 18, 1930, the day came to introduce Bleecker’s invention to the world. Paramount News was on location with a newsreel camera to record the momentous event.

“It had been four years since I came to the Curtiss Aeroplane and Motor Co., at the ripe old age of twenty-three, with my proposed helicopter design,” recounted Bleecker. “I had accomplished what no other helicopter researcher had achieved: vertical takeoff and landing, hovering in place, maneuvering in any direction at will, and gliding safely to a landing after simulating engine failure.”

Other helicopter prototypes created by Louis Brennan, Emile Berliner and George de Bothezat had performed one or two of these operations, but none had achieved them all—until now. The world would get its first glimpse of Bleecker’s new flying machine, but it would only be a glimpse, as the team had decided ahead of time that, due to a small oil leak and gusty weather, no public flight would be made. For now, they allowed people to inspect the craft, photograph it and ask questions. Bleecker would start the engine and let the rotor turn for a few minutes while the Paramount crew filmed a newsreel.

“We opened the huge sliding doors and wheeled the helicopter out onto the tarmac, where the crowd of about one hundred people swarmed around it, inspecting and photographing it from every angle, making notes, and asking me for statements to use in their news stories,” remembered Bleecker. “For the most part I lingered quietly by the cockpit, making sure no one fiddled with the controls.”

“…I have to admit, the machine looked pretty impressive out there in the brilliant sunlight, with its luminescent orange four-winged rotor, walnut propellers, and navy blue fuselage. It was truly a sight to behold. Soon the Paramount people indicated they were ready to film the newsreel, and I was asked to start the engine.”

Bleecker opened up the hinged nose of the tiny fuselage, climbed in and took the pilot’s seat. The crowd quickly backed away. On Bleecker’s signal, Blashiell generated a spark and the Wasp engine sprang to life. Immediately the propellers mounted on each rotor blade began to spin, which then caused the entire structure to revolve. It was far too noisy to hear anyone’s response, but Bleecker could see the expressions of amazement on people’s faces.

The rollout and demonstration received coverage in newspapers and magazines across the country. The September 1930 edition of Popular Science Monthly featured an article titled “New Plane May Fly Straight Up in Air” that included a detailed illustration explaining the helicopter’s controls. Paramount’s newsreel of the event was shown in theaters across the country.

It was a heady moment for young Bleecker. His achievement had thrust him into the forefront of flight experimentation among the great aviation pioneers. Judging by all the press attention, the Curtiss-Bleecker helicopter seemed destined for a place in history.

this article first appeared in AVIATION HISTORY magazine

Facebook @AviationHistory | Twitter @AviationHistMag

As the test flights progressed, Bleecker demonstrated that the helicopter was easy to fly, stable, controllable and maneuverable. He contacted Ted Wright in Buffalo to explain the need for a test pilot. Wright sent chief test pilot Harvey Ogden to Valley Stream so that Bleecker could tutor him in the basics of helicopter control. Before long Ogden had things well in hand and, over the next several months, he began making increasingly extended flights, reportedly reaching top speeds of 75 mph and altitudes of 1,000 feet.

But it was all about to come crashing down.

“One day early in the summer of 1931, we were conducting further flight tests,” Bleecker said. “I suddenly noticed that the little propeller cooling the Wasp engine had stopped turning. I frantically waved Harvey down. We quickly learned that a small double gear had failed. This was the second time that part had failed. Possibly the little propeller, in rotating over the cylinders and baffles, was going through fast aerodynamic load changes as the air resistance quickly varied, and this was wearing out the gear teeth.”

Bleecker proposed a gear that had a flexible connection between the upper and lower part of the double-gear arrangement. Drawings were made of the new gear and a shop order was issued for its manufacture. The total cost: $90.

“Imagine our shock when we learned that our order for one small gear had been denied,” he said.

Amid the first full year of the Depression, word came down from the company treasurer that they would “not spend a nickel on anything we are not getting paid for.” That meant all new projects not being funded by the government, including the helicopter. Barely a year after the triumphant public display, the financially strapped Curtiss Aeroplane and Motor Company abruptly canceled the project after having spent nearly $100,000 (about $1.5 million in today’s dollars) on it.

“Ted Wright suggested that I spend some time in Washington, D.C., to convince Navy brass of the helicopter’s usefulness,” recalled Bleecker. “Since this involved a lot of time being away from home, it was decided that my wife and children would go to her family’s farm in Michigan. I drove them to Grand Central Station, New York, and put them on a Pullman to Michigan. When I returned to my car, I discovered, to my total dismay, that the rear door had been jimmied open and the 16mm projector and—more importantly—around 4,000 feet of the movies of all our flights had been stolen. Not one single foot was left of any proof that the machine had ever flown!” Bill Valk, Curtiss’ patent attorney, was so upset that for three weeks he placed ads in every major New York City newspaper offering a sizable reward for the film’s safe return, with no questions asked, but nothing materialized.

“Seven years of my life’s pioneering work, all down the drain, just like that!” continued Bleecker. “Because there were no new news reports or flight films to reach the public, it was generally assumed that no breakthrough had occurred and it was just one more failed attempt to produce a successful helicopter. I had done everything possible to prove the practicality and success of an entirely new and uniquely useful form of aerial flight and, on the verge of a public demonstration proving all of this, the bottom had dropped out. That dreadful day [in late July 1931], I locked the hangar door and never saw my helicopter again!”

In 1965 Bleecker reluctantly attended a reunion hosted by the Curtiss-Wright Corporation, only to discover that he was the guest of honor. Ted Wright initially talked about Curtiss’ glory days, before its merger in July 1929 with Wright Aeronautical. He then attributed the company’s decline to two bad decisions. To illustrate one of these, a picture of the Curtiss-Bleecker helicopter was projected. “The abandonment of the helicopter after a minor gear failure, following extensive and highly successful flight testing, was one of two critically bad decisions,” said Wright. “The other was turning down the opportunity to secure exclusive rights to the Irving parachute.”

By then there was plenty of water under the bridge. Maitland Bleecker had survived the emotional tsunami surrounding his invention and gone on to live a very long, productive life. He died in October 2002, just shy of his 100th birthday. The fate of Bleecker’s helicopter—his crowning achievement—is unknown, though presumably Curtiss-Wright scrapped it.

Ed Hey became acquainted with Maitland Bleecker in 1970. He says Bleecker “was the most impressive man I’ve ever met.” Hey’s article is based on Bleecker’s 1996 book, My American Family: Riding the Winds of Change, and on discussions with Bleecker’s son, Allan.

This feature originally appeared in the May 2019 issue of Aviation History. Subscribe here!