In a world where the focus seems to shift daily from one technological wonder to another, the value of solid engineering—a design well thought-out and well executed—is too often overlooked. This is as true in jet aviation as it is anywhere else. Today more than ever it’s important to reflect on the work of pioneering aircraft designers, to better understand just what it takes to make a truly great airplane, then and now.

Ed Heinemann was once named by maverick designer Burt Rutan as among a handful of engineers who were the “pioneers who provided my inspiration.” I first came to appreciate Heinemann’s genius years ago as a young aerospace engineer, while I was conducting benchmarking studies for range and payload across a number of jet designs, the Douglas A-4 Skyhawk among them.

It’s easy to underestimate how phenomenal an accomplishment “Heinemann’s Hot Rod”—as the A-4 became known— truly was. By the time Heinemann conceived of the design, he had already proved his mettle with more than a dozen aircraft, leaving his distinctive imprint on virtually every fighter, strike aircraft or experimental airplane to come out of Douglas during the 1940s and ’50s. From the SBD Dauntless, which was instrumental in turning the tide at the Battle of Midway, to the experimental D-558-2 Skyrocket, which in November 1953 enabled Scott Crossfield to become the first man to fly at twice the speed of sound (see “Skyrocketing Through Mach 2,”), Heinemann’s team of engineers was a breed apart.

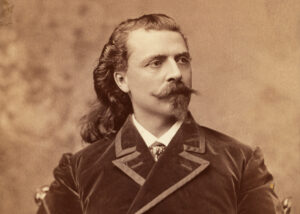

Known widely as “Mr. Attack Aviation,” Heinemann himself never completed a formal degree as an engineer. He rose through the ranks, first as a draftsman, then as an apprentice to and colleague of other legendary aircraft designers—Donald Douglas, Jack Northrop and Howard Hughes among them—before finally becoming Douglas Aircraft’s design engineering chief. He had learned engineering on the job, hands-on, and was widely recognized for his natural talent.

When the U.S. Navy first approved Douglas in January 1952 to design a new carrier-based strike jet, capable of carrying a 2,000-pound payload up to 300 nautical miles, with a maximum speed of 500 knots and a maximum takeoff weight of no more than 30,000 pounds, Heinemann confidently predicted that he could deliver the requested range and payload in an airplane that weighed less than half the Navy’s requirement, and with a top speed 90 knots faster. What he proposed seemed impossible—an airplane too good to be true. And when the Navy nonetheless signed a contract putting Heinemann’s confidence to the test, Admiral Thomas S. Combs emphasized in no uncertain terms that the strike jet was expected to meet all the Navy’s objectives, and that it also “absolutely must not exceed one million dollars per copy.” As time would prove, Heinemann’s team delivered on every one of those promises: range, payload, takeoff weight and cost.

How did Ed Heinemann succeed in doing what the experts of his day had not imagined was possible? Some new super-secret alloy? A secret engine? No, nothing so elaborate. Heinemann succeeded by applying the first principles of engineering and by merciless attention to detail. Every aspect, every element of the airplane was scrutinized to reduce weight. Every unnecessary redundancy was challenged.

After considering a swept-wing design, as was fashionable at the time, Heinemann’s team at El Segundo, Calif., selected a delta-wing configuration with a span short enough to avoid having to fold the wings to fit on a carrier deck. It also provided for maximum wing-root thickness, stiffness and fuel capacity. Eliminating the wing-folding mechanism alone saved an estimated 200 pounds. The airplane’s black boxes, including the communications, navigation, IFF and power supply systems, were consolidated into a single unit, for a weight savings of some 40 pounds. The Skyhawk’s ejection seat was similarly redesigned to eliminate a third of its parts, coming in at 58 pounds below the original weight estimate—less than half what the standard Navy ejection seat weighed. And when the subcontractor assigned to design the air conditioning system showed up at Heinemann’s door with a unit that was 20 pounds over target, he was told to come back when it met the required weight. The air conditioning unit eventually came in at 5 pounds below the weight that Heinemann’s team had allotted for that system.

When the first XA4D-1 rolled out of the assembly floor, it weighed 7,896 pounds, more than 270 pounds below the target empty weight that Douglas had signed up for. And when the Skyhawk finally reached production, the first 500 airplanes would cost an average of $860,000 each, well below the Navy’s $1 million upper limit.

Ed Heinemann’s guiding principles—simplifying every component to its bare minimum, combining functions into fewer components and designing direct load paths that maximized structural synergy—were reflected throughout the airplane. The main landing gear, for example, was anchored directly into the main wing spar, providing a straight load path between landing gear forces and the airframe. The main wing spars themselves were machined from a single forging, eliminating the need for fasteners between spar elements. And the skin of each wing was formed from a single sheet of aluminum, again eliminating the need for extra fasteners and maximizing structural strength.

The XA4D-1 first flew on June 22, 1954, with the last production aircraft rolling off the assembly line in February 1979. A total of 2,960 Skyhawks were produced during those 25 years. Heinemann’s team had shown the same dedication to simplification inside the cockpit that they had displayed throughout the structural design, reducing instrumentation by roughly two-thirds compared to the F3D Skynight that had preceded it. As one pilot said of his first A-4 flight: “It scared me to death for the first half-hour. I kept looking around the cockpit for something to do. But it was so simple to fly there really wasn’t much to do! I merely got in, started up, took off and enjoyed it.”

Despite its diminutive size, the Skyhawk quickly demonstrated its ability to carry far larger bombloads than the 2,000 pounds that the Navy had specified. Beginning with the A4D-5 (later A-4E) model, the external stores stations were increased from three hardpoints to five, upping external capacity to 8,200 pounds. The A-4E also introduced the Pratt & Whitney J52 engine, increasing available thrust from the 7,700 pounds of the original Westinghouse J65 engine to 8,500 pounds in the J52-P-6A. Later versions of the J52 produced even more thrust, eventually culminating in the A-4M/N models’ J52-P-408, which produced 11,200 pounds of thrust and increased the external weapons load to some 9,155 pounds. Not bad for a “light attack” jet. None of these later upgrades would have been possible, however, without the sound foundation established by Heinemann and his team so many years before.

To appreciate just how good the structural design of the A-4 really was, it’s useful to compare its empty weight to its maximum takeoff weight on a logarithmic basis. Comparisons like this are routinely used in conceptual design, to gauge how heavy an airplane will need to be to perform its required mission. Drawing on the published literature, and comparing the A-4 to its peers across decades of jet aviation, it is readily apparent that the Skyhawk far exceeded the maximum takeoff weight that was considered the norm for a fighter-bomber of its size. When viewed in this fashion, only a handful of strike aircraft, developed decades after the A-4 and with the benefit of composites and other structural technologies unavailable when it was designed, would actually exceed the standard the Skyhawk set.

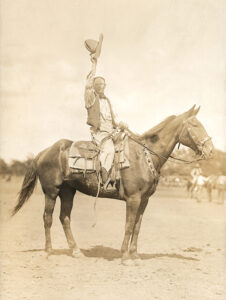

The A-4 formed the backbone of U.S. Navy and Marine Corps close air support and strike capabilities throughout the Vietnam War. Navy Skyhawk squadrons made 107 cruises to Southeast Asia, as compared to 84 for the F-4 Phantom. Assigned to the most dangerous attack missions, the Skyhawk also racked up the most combat losses, though only one fell to an enemy MiG. All the other losses were attributed to groundfire or SAMs. The Skyhawk also flew into battle with the Israeli Air Force in the course of three wars. Stunningly nimble when stripped of its bombload, it would serve for decades more in the adversary units providing opposition for the Navy’s “Top Gun” air combat training program. And in 1991—nearly 40 years after the first prototype flew—the A-4 would again serve in combat during Operation Desert Storm, as part of the Kuwait air force. The last TA-4 was not retired from active Navy service until May 2003, a testament to the enduring legacy of Heinemann’s design.

It has been more than 20 years since I graduated with my degree in aerospace engineering. I’ve worked on many exciting programs, using materials that were not even envisioned when Ed Heinemann drew up the first plans for the A-4, and applying computer design tools that were never imagined in his day. Yet I still look back with admiration at what Heinemann and his El Segundo team accomplished. There are things I learned from the A-4 that I’ve carried with me throughout my career.

First, an airplane that is truly devoted to its task, whose design is not diluted by extraneous objectives, can achieve much and exceed all expectations. Second, I learned to be impressed more by results and less by titles. Heinemann’s skill and experience was worth more than a roomful of degrees. I also learned that big solutions begin with little thought experiments, sketched out on small pieces of paper. As Ed used to remind his staff at El Segundo: “Paper is cheap! When beginning a project, sketch out all your ideas and concepts. Dream a lot. Let your mind freewheel. You can’t go wrong, no matter how many sheets you fill out and toss into the wastebasket.” And above all, he understood that engineering is a team sport: “Aircraft development is an evolutionary process. What flies today is an outgrowth of what flew yesterday. The knowledge of aeronautics has flowed from a wide range of sources, and designers benefit from the efforts of others. No single person could do it all.”

The A-4 was a remarkable achievement that served the U.S. and its allies well in wartime and peace. As Heinemann himself wrote: “I believe that the aircraft’s most significant contribution revolves around how it proved that with diligent engineering, hard work, and continuing cooperation between builder and buyer, wonders can be worked. Wonders that last a very long time.”

Engineer John Golan has worked in the U.S. aerospace industry for more than two decades as a designer, structures analyst and engineering manager on a variety of civil and military jet propulsion systems. For further reading, he recommends: Douglas A-4 Skyhawk, by Jim Winchester; Ed Heinemann: Combat Aircraft Designer, by Edward H. Heinemann and Rosario Rausa; and Aircraft Design, by Edward H. Heinemann, Rosario Rausa and K.E. Van Every.

This feature originally appeared in the January 2015 issue of Aviation History. To subscribe click here!