The first American company to develop a jet engine, General Electric went on to produce the best-selling turbojet ever.

For a company whose engineers had helped develop the United States’ first jet-powered fighter during World War II, General Electric found itself facing an uncertain future in jet engine manufacturing at war’s end.

GE’s engineering whiz kids had taken a revolutionary turbojet conceived by Royal Air Force officer Frank Whittle and developed their own version in six months. Yet with victory finally in hand, U.S. military contracting officials transferred GE’s jet engine designs to competitors—leaving GE’s aviation engine division virtually empty-handed and facing a possible shutdown.

How could that happen? And how did that division succeed, despite the federal snub and a near-rebellion by many of its most loyal employees, to rebound with the best-selling jet engine of all time?

GE executives had readily accepted Maj. Gen. Henry H. “Hap” Arnold’s challenge to adapt Whittle’s engine to counter jet aircraft being rushed ahead by Germany’s Luftwaffe. Arnold, the Army’s deputy chief of staff for air in 1941, chose GE for the project instead of Pratt & Whitney or Wright Aeronautical, both of which were busy producing piston engines for the nation’s fighters and bombers. He believed that GE was better positioned to give priority to the project, and that it had relevant experience manufacturing superchargers for high-altitude flight. He also suspected GE might be more receptive to a radically new power plant than companies already prospering by turning out piston engines.

“Gentlemen, I give you the Whittle engine,” Arnold told GE executives at a top-level briefing on September 4, 1941, as he handed them a confidential sheaf of plans and specifications. “Consult all you wish and arrive at any decision you please—just so long as General Electric accepts a contract to build 15 of them.”

GE’s leaders signed the contract in October, only weeks before the Pearl Harbor attack. Whittle, flown in secretly from England to join the American team, was on hand a year later to watch as Bell Aircraft’s XP-59A Airacomet, powered by two GE-modified Whittle engines, blasted into the air from Muroc Dry Lake in California for a successful test flight in October 1942. The Airacomet achieved flight despite a thrust of only 1,250 pounds per engine, modest by later standards.

While the Americans worked to improve the Airacomet’s performance, Allied intelligence reported in 1943 that the Luftwaffe had already test-flown two jet aircraft. GE rushed work on a new engine designed to leapfrog German aviation technology, but the U.S.—unlike Germany—wouldn’t get a jet fighter into combat before the war ended.

Within a month after GE began testing that new engine, later designated the J33, it exceeded its contracted 4,000 pounds of thrust (eventually reaching 5,200 pounds). By June 1944, it powered the Lockheed XP-80 Shooting Star, the Army Air Forces’ first operational jet fighter. (A later version would establish a world speed record of 623 mph in 1947.) Although the Germans surrendered before the P-80 could be tested in combat, GE emerged from the war with a formidable reputation.

Despite the company’s accomplishments, GE struggled to meet all its military commitments in the postwar market. It was unable to test its improved J35 in a Republic XP-84 Thunderjet until February 1946. By then the Army Air Forces had pressured GE to license production of its J33 to General Motors’ Allison Motor Division and the more advanced J35 to GM’s Chevrolet Motor Division. After Chevrolet bowed out to concentrate on automobiles, Allison was licensed to mass-produce both engines and would emerge as a major competitor for GE.

The military’s licensing decision, which closed GE’s Syracuse, N.Y., plant and idled many employees, could have stripped GE of its future in aviation. Fortunately for the company, Harold D. Kelsey, who had overseen its supercharger production during the war, became managing engineer of the newly named Aircraft Gas Turbine Division in January 1946. Kelsey figured that although the military could farm out GE’s two major engine projects, it couldn’t take away the know-how his engineers gained in creating them.

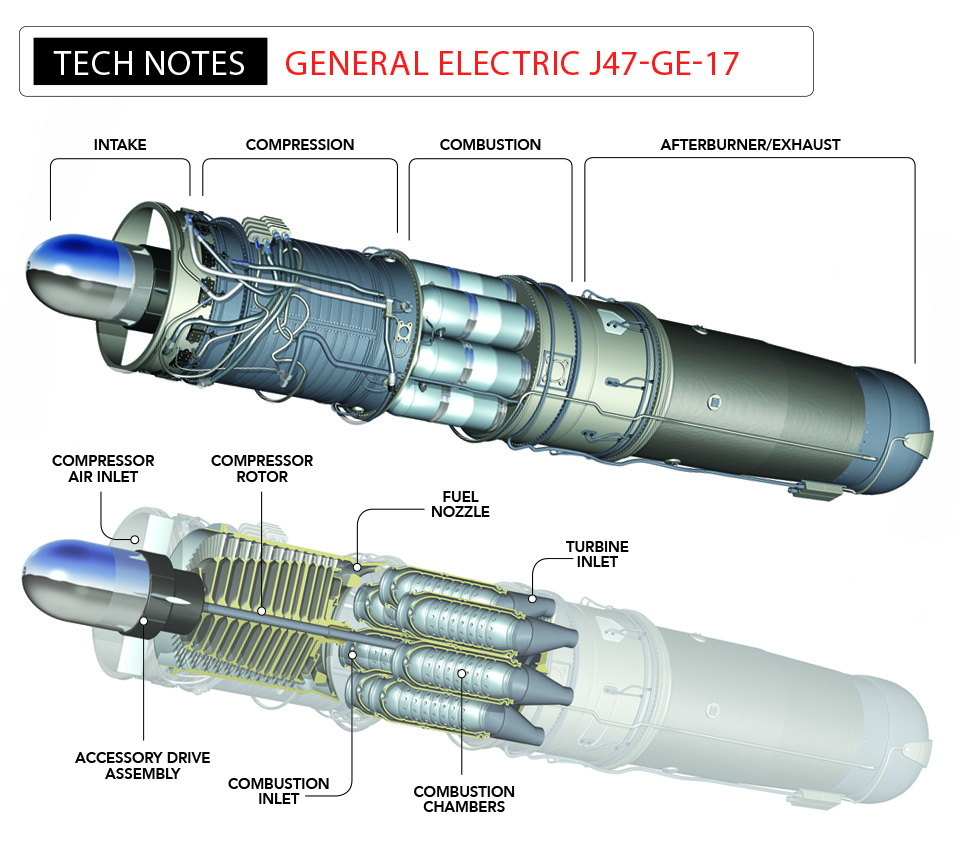

Focusing on the advances achieved in developing the J35, Kelsey and his team were by early 1948 hurrying to create an improved turbojet. Like the J35, it would be built around an axial-flow compressor instead of the centrifugal-flow compressors on which GE had focused after inheriting the Whittle engine project.

Centrifugal-flow compressors spin the incoming air in a circular casing, increasing pressure by forcing the air against the outer casing wall, a process not unlike swinging a bucket of water rapidly in circles without spilling. The axial-flow concept, on the other hand, uses a series of blades mounted on a rotating shaft combined with stationary blades mounted in the casing to compress air as it moves straight through an enclosed tube.

“My biggest contribution was to get General Electric into engine production,” Kelsey said in the GE history Eight Decades of Progress. “I made the decision to drop centrifugal engines and concentrate on the axial-flow type.” Yet critics inside and outside the company, who resisted Kelsey’s initiative throughout his three years leading the division, questioned his decision. They pointed out that centrifugal designs were much simpler, used fewer parts and cost less to manufacture than axial-flow engines.

Kelsey’s team countered that axial-flow engines offered almost unlimited growth potential, since they allowed higher pressure ratios promising greater future power. They were also much more streamlined than centrifugal engines saddled with a large frontal surface. Drag would only increase as military planners inevitably demanded greater thrust from centrifugal power plants, requiring larger intakes.

German companies working for the Luftwaffe had focused on axial-flow technology since the mid-1930s, with Junkers and BMW producing axial turbojets late in the war. Only Junkers’ Jumo 004 achieved mass production, powering the Messerschmitt Me-262As that attacked Allied bomber formations from late summer 1944 onward. The Me-262s proved to be lethal weapons, but arrived too late to affect the war’s outcome.

Committed to the axial-flow approach, the GE team forged ahead. They persuaded Army Air Forces planners that they could produce a jet engine incorporating the world’s first electronically controlled afterburner to help generate in excess of 25 percent more thrust than the J35. What’s more, they promised to match Allison’s commitment for delivering the licensed J33s and J35s with an equal number of the new engines. It was an offer the Army Air Forces couldn’t refuse.

First, though, Kelsey and his staff had to persuade their management to keep GE in the aviation engine business and fund the new project. They assured top executives that the jet engine business would produce $35 million a year by 1950, an estimate that would prove to be one-tenth of the actual figure. Convinced that Kelsey’s team could deliver, management backed them with a massive investment in personnel and facilities. The costly gamble would assure development of an even more advanced engine, the J47. Its introduction in 1948 reestablished GE as a frontrunner in the aviation industry.

J47 engines were in growing demand by the spring of 1948, as the Cold War heated up after the Soviet Union sealed off its sector of occupied Berlin. But GE officials faced a frustrating dilemma: The J47s couldn’t be delivered because they were flunking a critical test at the company’s plant in Lynn, Mass. Thirty of the urgently needed engines sat in sealed containers behind the plant. Tests indicated they were exceeding GE’s promised fuel consumption, and nobody could figure out why.

Fortunately for GE, it had recently hired a talented engineer with a keen eye and an unusual background story. During WWII, German-born Gerhard Neumann had provided valuable wartime support to U.S. forces in China. No friend of his country’s Nazi leadership, he had fled Germany and accepted a job as a mechanic with the American Volunteer Group, the famed “Flying Tigers.” His work for the AVG included rebuilding a downed Japanese Zero and delivering it to American investigators eager to learn its secrets. He also served as a spy behind Japanese lines to bring back airpower intelligence. Those actions helped the “enemy alien” win both U.S. Army master sergeant’s stripes and, through congressional action, U.S. citizenship.

As a newly minted citizen in China, Neumann concluded that his future lay in the United States, half a globe away. He and his American wife, Clarice, made their move the hard way—in a war-surplus jeep, traveling 10,000 miles across Asia and the Mideast. Intrigued by the possibility of joining GE, he sent a letter from Iran to the company’s plant in Lynn. Company managers found Neumann’s battlefield engineering experience and ability to improvise an attractive combination.

On his lunch break at the new job, Neumann sat down behind the Lynn plant to observe the shack and standpipes where GE calibrated its engines’ fuel consumption. The electric timers that measured fuel flow into the engines were accurate to within one one-hundredth of a second. Yet he suddenly realized that, depending on the ambient temperature, some of the fuel remaining after an engine test lingered in the unprotected standpipes and wasn’t being measured. He hurried to share the good news with his supervisor.

“The fuel-flow instrument calibration was in error,” Neumann later explained in his autobiography, Herman the German. “The 30 held-up engines were permitted to be shipped because they were indeed all right.” The logjam had been broken by a man who would break many more in a noteworthy career with GE.

The demand for J47s grew so fast that not even an expanded Massachusetts plant could cope with it. And GE’s leadership knew the company couldn’t afford to surrender its lead to competitors once again.

A search team located an unused government-owned plant in Lockland, Ohio, where Wright Aeronautical had manufactured engines during WWII. The complex included a building once considered the world’s largest under a single roof. It was so sprawling that Orville Wright, guest of honor at the dedication ceremonies, had wandered off to inspect the cavernous structure and had to be tracked down before the festivities could begin.

GE transferred 150 engineers from Lynn to update the aged facilities, which had been idle for three years, to begin producing J47s. One of their first major challenges was to transform the plant’s 40 piston-engine test cells into 14 larger and more sophisticated cells for jet engines.

The new plant officially opened on February 28, 1949, as the first Ohio-built J47 engine was delivered to the now-independent U.S. Air Force. By the end of the year, the plant was turning out 200 engines a month, soon to bypass the Lynn plant as the Korean War pushed its workforce from 1,200 to 12,000. Known as the Evendale plant, the facility would eventually be designated to build all of GE’s large jet engines and serve as headquarters for its Aviation Division.

In June 1950, Communist North Korean troops poured across the 38th Parallel to invade South Korea. As U.S. forces were rushed to Korea to help stem the tide, the demand for J47 engines skyrocketed. Soon, J47s powered virtually all the military’s frontline aircraft, including the North American F-86 Sabre interceptor and six-engine Boeing B-47 Stratojet. The F-86 saw extensive combat against Soviet-built MiG-15s, chalking up an impressive kill record, while the B-47 would serve as the Air Force’s dominant medium bomber for years after the war.

GE delivered more than 35,000 J47s by the end of the 1950s, making it the world’s most produced gas turbine. But if the J47 virtually owned the military aircraft engine market during the late 1940s and early 1950s, a competitor beat it to the punch with a follow-up design. Pratt & Whitney, which had dominated piston-engine development during WWII, blindsided GE with its J57. The new engine was touted as offering better performance, increased reliability and greater fuel efficiency. Military purchasers agreed. The Air Force promptly bought the J57—twice as powerful as the J47, with 10,000 pounds of thrust—for aircraft ranging from the F-100 Super Sabre, the first Air Force jet capable of routinely exceeding the speed of sound, to the huge, eight-jet Boeing B-52 strategic bomber that remains in the military fleet to this day.

Furthermore, both Boeing and Douglas selected Pratt & Whitney’s civilian variant for their first generation of commercial jetliners, a market GE had yet to penetrate. Pratt & Whitney opened a new facility in Palm Beach County, Fla., billing it as the world’s most advanced for designing and testing jet engines.

By 1952, GE Aviation executives found themselves on the defensive, hurrying to replace the J47. One promising concept, for an engine that could propel aircraft at twice the speed of sound, was plagued by a tendency of its compressor to stall, sometimes violently, during testing. Frustrated GE executives turned to Gerhard Neumann to lead a team in building a full-scale version of a design he had proposed featuring “variable stator” blades that helped the compressor cope with the huge internal variations in airflow experienced from takeoff to supersonic speeds.

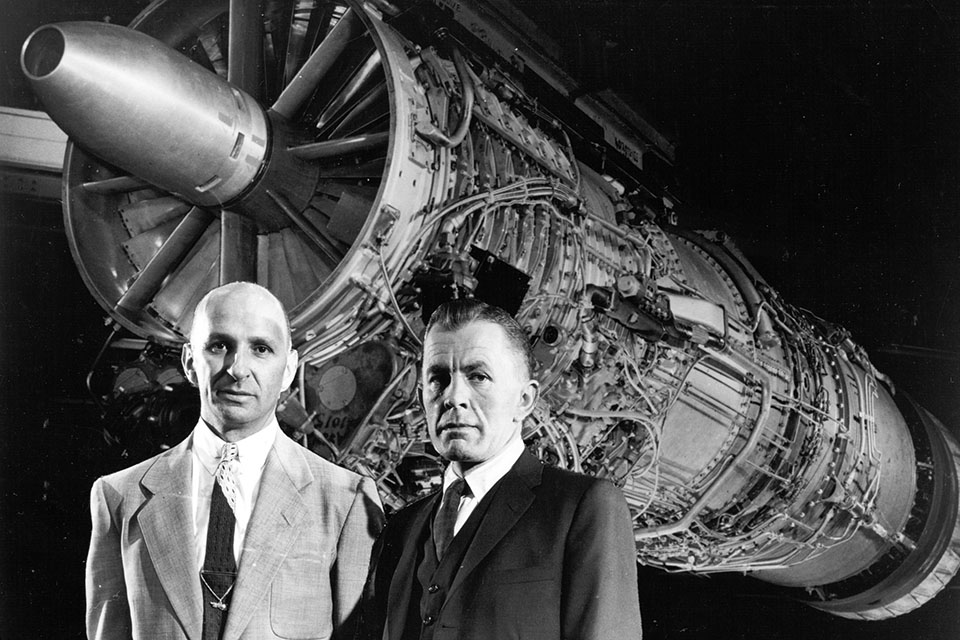

Air Force officials were so impressed with the resulting J79 that they began ordering the engine to power such pace-setting aircraft as the Lockheed F-104 Starfighter, McDonnell F-4 Phantom II and Convair B-58 Hustler. According to Fortune magazine, the J79 engine “probably saved GE’s big jet-engine business from collapse.” It also helped win a 1955 promotion for Neumann to manage GE’s Jet Engine Department at Evendale.

For their leadership in developing the J79, Neumann and Neil Burgess won a prized Collier Trophy in 1958, and Lockheed’s Clarence “Kelly” Johnson won for the F-104 that it powered. It was a sweet victory, for the 1952 Collier Trophy had been awarded to Pratt & Whitney’s corporate parent, United Aircraft Technologies, for the J57 and the Vought F8U Crusader that it powered.

Over a 30-year period, more than 17,000 J79s would be built. GE Aviation was back on track in the continuing battle to propel the aircraft industry into the next generation of flight.

Meanwhile, the famed J47 ended its record production run in 1956 after a decade of pioneering advances critical to turbojet technology. Ironically, the engine’s reliability helped limit its production. The Air Force had contracted for many additional J47s, but improvements made through the years stretched out the engines’ operational life and saved the government $200 million. Given the turbojet’s many achievements, it seemed appropriate that the J47 would end production on a positive note. J

Veteran journalist and aviation writer Don Bedwell is the author of Silverbird: The American Airlines Story. He thanks GE retiree Robert D. Johnson for providing perspective on GE during the J47 era. Further reading: GE’s Eight Decades of Progress: A Heritage of Aircraft Turbine Technology; and Herman the German, by Gerhard Neumann.

This feature originally appeared in the March 2017 issue of Aviation History Magazine. Subscribe today!