The Boeing 247 was the end result of a battle between company management and its engineers. Unfortunately, the engineers lost. Although enshrined today as “the first modern airliner”—and it certainly looked the part—the 247 was actually too small and low-powered to make it as a money-making passenger carrier. It was the wrong airplane at the right time.

That time was the early 1930s, when a series of events and innovations was transforming air transportation. Until then commercial aviation had been a cold, miserable, noisy, cramped, vibratory and often vomitous experience. Airline passengers flew aboard drafty biplanes, three-engine antiques with fixed landing gear and a shrubbery of struts and rigging. Operators offered no creature comforts, and passengers were little more than an afterthought, since carrying government-subsidized airmail paid the bills. According to Transcontinental and Western Air pilot Daniel W. Tomlinson IV, “Flying in the old Ford [Trimotors] was an ordeal…. The flight was deafening. The metal Ford shook so much that it was an uncomfortable experience. It surprised me that people would pay money to ride in the thing.”

At that time, the Boeing Aircraft Company had no experience designing passenger airplanes. It built biplane pursuits for both the Army and Navy, as well as two mail plane designs and a surprisingly modern bomber for the Army. Boeing’s first passenger airplane was the 1925 Model 40A, a single-engine, fixed-gear biplane with space for just two passengers in a pair of tiny, handsomely wood-trimmed, enclosed cabins, each with its own door, below and ahead of the pilot’s open cockpit. The original plan was that those cabins could be occupied by a riding mechanic and, if necessary, a deadheading pilot.

Boeing built only one straight Model 40, since it was powered by an oily and obsolete Liberty V-12 engine. The company replaced it with the just-introduced 410-hp Pratt & Whitney Wasp radial. The Wasp was 200 pounds lighter than the World War I Liberty, which meant the new Model 40A could carry 200 pounds more mail. The slightly widened 40C could also accommodate four riders.

The Model 40s all made extensive use of welded steel tubing for the fuselage structure, since Boeing had pioneered the precise fitting, beveling and electric arc-welding of thin-wall steel tubes. The company initially applied the technique to a 1923 Army contract for 22 de Havilland DH-4s, with welded steel tubing replacing the original spruce-framed fuselage. They were called DH-4Ms, the M standing for “modernized,” not “metal.” (Outmoded as they were, the DH-4Ms made at least a minor amount of history. In 1927, serving as Marine Corps Boeing O2B-1s, several carried out the first dive-bombing attacks ever flown by the U.S., against Nicaraguan rebels.)

Despite the discomfort, passenger demand soon outstripped the Model 40C’s four seats. Most of these airplanes were flying for Boeing Air Transport, which the company had formed in 1927 when it won the lucrative San Francisco-Chicago airmail route. Boeing also realized that it would be convenient to have a captive customer for its civil products. (After a variety of name changes, BAT became what we now know as United Airlines, which is still happy to fly Boeings.)

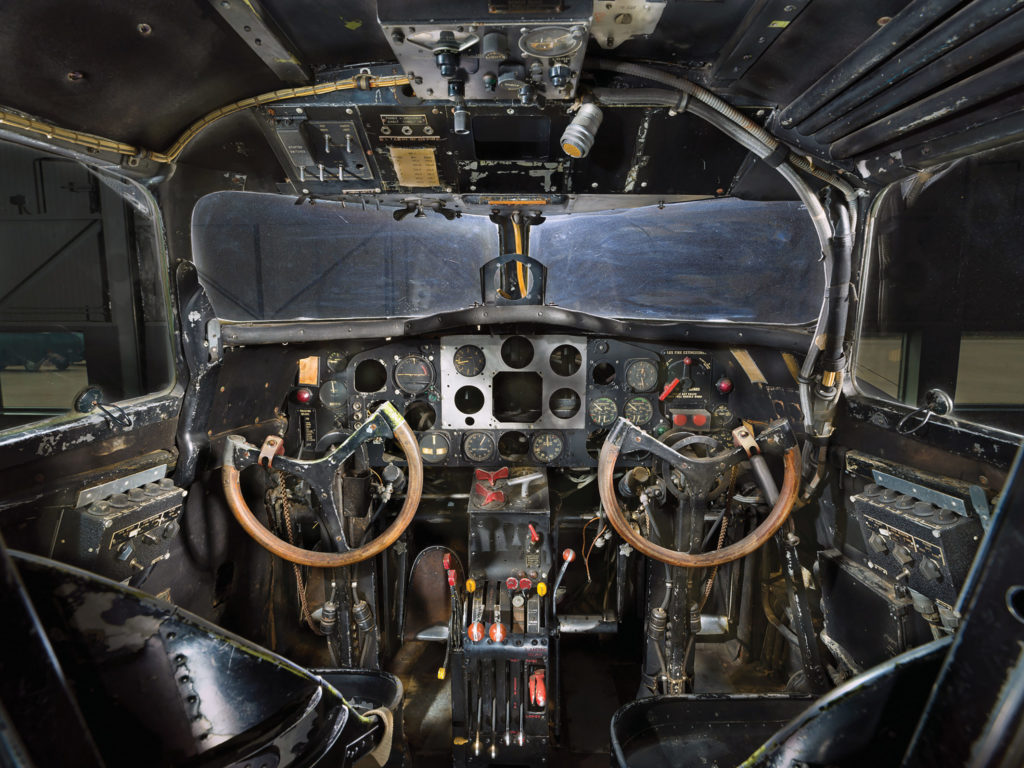

Boeing realized that it needed a bigger passenger carrier, so it introduced the Model 80, a not particularly attractive 12-passenger trimotor biplane soon lengthened to carry 18. The 80 was Boeing’s first real focus on passengers rather than mail. Boeing considered the airplane to be the Pullman of the skies—a luxurious railway coach with wings, though that was largely a PR fantasy. The 80A did have leather chairs for seats, a small amount of hot and cold running water in a tiny lavatory and a heated cabin. The 80A was also the airliner that finally convinced pilots they didn’t have to sit in open cockpits so they could feel the wind on their cheeks and keep the airplane trimmed and coordinated like human yaw strings. They also didn’t have to squint through rain and snow at the engine nacelles to read the pressure and temperature instruments. In the Boeing, those instruments were on the flight-deck panel.

The Model 80A also introduced to aviation what would quickly become an airline necessity: the flight attendant, then called a stewardess. Boeing Air Transport hired registered nurses to fly aboard its Model 80As, supposedly to cater to the possible medical needs of passengers. In fact, their presence was a goad to potential businessman passengers who still distrusted aviation. “Afraid to fly? Well, here’s a young lady braver than you.”

Boeing had been lining its mail plane cargo compartments with an aluminum alloy called Duralumin to keep metal fittings on mailbags from tearing through the fuselage fabric. Duralumin was the first metal light enough to be carried aloft en masse by the engines of the time, and Boeing chief engineer Claire Egtvedt mused that perhaps an entire stressed-skin, semi-monocoque fuselage could be formed of Duralumin. (Jack Northrop had already figured that out with the Northrop Alpha, so Boeing bought Northrop’s company, Avion.) That was a challenge to Boeing’s conservative approach, as well as the industry’s. Until then, the Ford and Fokker technique was to use corrugation to provide structural strength for metal, but it turned out that the drag of the corrugations, even though they were in line with the assumed airflow, was greater than anticipated. Egtvedt called those airplanes “flying washboards” and he intuited that a rounded fuselage would create less drag than the boxy style of the time.

Egtvedt had moved on to Boeing’s executive ranks by the time the company’s pioneering Model 200/221 Monomail emerged under the stern gaze of engineer Charles “Monty” Monteith in 1930. (Monteith was so conservative he insisted that his staff draw up just-in-case alternative biplane configurations for every Boeing design, even the 247.) The Monomail was an all-metal, semi-monocoque, retractable-gear design with a neatly cowled radial engine. The Model 200 was a pure mail plane, the 221 a six-passenger transport soon to be stretched to accommodate eight. Both variants set new standards for low-drag aerodynamic efficiency—so much so that the Model 200/221 outflew its powerplant. With a prop pitched for a reasonable takeoff, the airplane cruised too fast to make use of that blade angle. The airplane needed a variable-pitch propeller, which hadn’t yet been developed.

Much of what made the Monomail special was carried over to an imaginative Boeing Army bomber contender, the YB-9. Though Boeing built only seven YB-9s—it was trumped by Martin’s faster and more modern B-10—the B-9 did have one new feature that became commonplace for multi-engine aircraft. Its engines were not carried in draggy, free-standing, strutted nacelles but were faired into the leading edges of the wing. This created better prop efficiency and smoother airflow over the wings.

On March 31, 1931, a pug-nosed TWA Fokker F-10 trimotor crashed outside Bazaar, Kansas, killing the much-admired Notre Dame football coach Knute Rockne. The accident happened because the Fokker’s wooden wing spar had rotted and failed, moving the Department of Commerce essentially to ban trees for airliner construction. Both Boeing and Douglas Aircraft immediately embarked upon the design of all-metal airliners.

The Northrop Alpha, the Boeing Monomail and B-9, the Knute Rockne crash, the adoption of stressed-skin semi-monocoque construction, cantilever wings, retractable landing gear, drag reduction through streamlining…once all this came together, the time had come for Boeing to create the 247.

Initially, Boeing management wanted to build a new metal airliner the size of the 18-passenger Model 80A, but cautious Monty Monteith felt that building a fast airplane of that size would be “like flying a barn door in a Kansas windstorm.” He advocated for a smaller design. Those initial 247 proposals included a biplane trimotor and a high-wing monoplane twin before Boeing finalized the low-wing configuration.

By 1929, Boeing had acquired a number of aviation-industry companies, including Stearman, Chance Vought, Sikorsky, Pratt & Whitney and, in 1930, Jack Northrop’s Avion. It now called itself the United Aircraft and Transport Corporation, so there were a number of cooks stirring the broth that became the Boeing 247. Two of the most knowledgeable chefs were Frederick Rentschler, founder and president of Pratt & Whitney, and his chief engineer, George Mead. (Mead designed many of P&W’s most powerful radials, including the ubiquitous R-2800.) But the pilots who flew for Boeing’s United Air Transport stuck their spoons in the design discussion as well.

Pratt had two engines that could power the 247: the 1,860-cubic-inch Hornet radial and the 1,340-cubic-inch Wasp. Using the Hornet would have resulted in a 16,000-pound airplane. To quote Henry Holden’s book The Boeing 247: the First Modern Commercial Airplane, “The pilots flatly refused to accept the Hornet engines, stating that a 16,000-pound airplane was too heavy and too powerful to land safely at some smaller airports.” Their demand for a 12,000-pound Wasp-powered airplane, which became the 247, was a fatal mistake. It meant the 247 would be an unprofitable 10-passenger transport at a time when 14 passengers was typical and Douglas’s DC-3 would have seats for 21. Even the Ford Trimotor held 11.

But a smaller airplane meant the two Wasps would produce a cruise speed of up to 165 mph, making the 247 briefly the fastest multi-engine airliner in the world. Cruise speed would go up to 180 mph with the 247D version, allowing United to advertise it as the “3-Mile-a-Minute Airliner.” The 247D had uprated 550-hp Wasp engines, two-blade variable-pitch props, a full set of deicing boots, efficient NACA engine cowls and other detail improvements, eventually increasing the 247’s top speed to 200 mph, cruise from 161 to 189, range from 485 miles to 750, service ceiling from 18,400 feet to 25,400 and single-engine ceiling from a paltry 2,000 feet to 11,500. (The 247 was the first twin-engine airplane able to fly on one engine.) There were other upgrades in radio and navigation gear, many of which would also find their way aboard earlier 247 models.

The D was the only 247 production variant. The 247B was to be a flying post office with a small staff of mail clerks doing in-flight mail sorting. The 247F was planned as a 12-passenger, Hornet-engine model. And the 247S would have had Besler steam engines, a possibility that Boeing briefly pursued because Beslers, though heavy, were near-instantly reversible, which would have permitted very short landings. (Only one Besler ever flew, in a Travel Air 2000. The engine put out about 150 hp but weighed a quarter of a ton.)

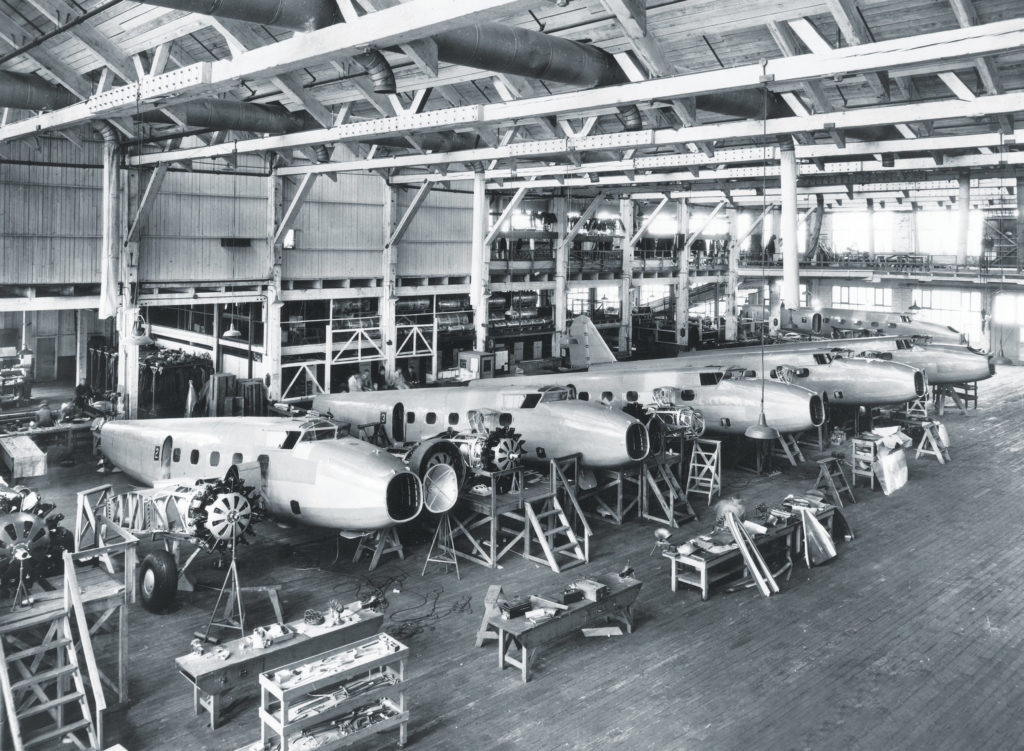

The first 247 took to the sky on February 8, 1933. By the time it stopped producing them later that year, Boeing had built only 75, and it reserved 60 of them for its in-house airline, Boeing Air Transport. The United Aircraft Corporation bought 10 and the rest went to Luft Hansa and a buyer in China. Trans World Airlines president Jack Frye wanted to buy 247s but was rebuffed, so he immediately turned to Douglas Aircraft, which happened to be prototyping what became the DC-1. TWA funded the program and became its launch customer. (Douglas built only one DC-1; TWA actually got DC-2s, and soon thereafter DC-3s.) The DC-3 would end up putting the little Boeing out to pasture in less than three years of mainline service. Douglas ended up manufacturing some 16,000 DC-3s and its C-47 military variant. Boeing never sold another 247. So if nothing else, the 247 can take some credit for the ascension of the DC-3.

In certain ways, though, the 247 indeed was the first modern airliner, despite its overall failings. One of its innovations was pneumatic deicing boots on the wing and tail leading edges, which had been invented by one Thorp Hiscock, William Boeing’s brother-in-law. Hiscock saw an iced-over flag shed its coating when the wind made it move, and he realized that if he could make the leading edge of a wing move by periodically pumping air through a rubber bladder, it too would shed ice. Monteith had resisted their installation, complaining that they added too much weight. He also feared (wrongly) that they would trap moisture and corrode the aluminum underneath them. The boots were initially fitted to the 247D, but were soon retrofitted to most earlier 247s, and Hiscock’s approach near-universally prevailed until turbojet airliners showed up with an abundance of hot air, some of which could be pumped through the leading edges of their wings, tails and engine nacelles to melt ice.

The 247 also had control-surface trim tabs that were movable in flight. Until then, trim tabs were adjustable only on the ground. United operated a 247 as a flying laboratory, and it exposed the need for conductive trailing-edge wicks to dispel the static electricity that had been interfering with radio communication in metal aircraft, so static wicks were another 247 innovation, as was a heated pitot tube.

Perhaps most important, the 247D had hydraulic controllable-pitch propellers, which had just been developed by the French company Ratier and licensed in the U. S. by Thomas Hamilton, founder of the Hamilton Standard propeller company. The all-important hydraulic mechanism had been developed by Ham Standard engineer Frank W. Caldwell. In practice, the 247D’s props had two positions: fine pitch for takeoff and climb, coarse pitch for cruise. Though Monteith inevitably thought the props were too heavy to adopt, they turned out to substantially improve the 247’s takeoff performance and cruise speed.

Boeing was so weight-conscious about the 247 that it even eliminated the simple cutoff switches that shut off the retraction motors when the landing gear reached the full-up position. This resulted in a slew of burnt-out motors when busy pilots forgot to monitor the gear-retraction process. Boeing had even planned to forego painting its 247s in order to save 50 pounds of Duco enamel. Instead, they anodized the Duralumin to give the airplane a distinctive gray-green mien. The anodizing process was uneven, however, producing a patchwork of differently shaded panels that made passengers worry they were boarding an airliner that had been repaired after an accident. United eventually painted its 247s battleship gray.

The 247’s characteristic visual feature was its backward-sloping windshield, a beetle-browed configuration that Boeing adopted from various Fokker airliners because conventional windscreens reflected the instrument lights back into the cockpit at night. Unfortunately, all that Boeing accomplished with the backward-slanting glass was to reflect ground lights at night, which was especially bothersome during landings. Boeing engineers finally solved the problem by inventing the glareshield. Virtually all 247s were then fitted with conventional windscreens, which turned out to have a bit less drag.

The 1934 MacRobertson International Air Race, from London to Melbourne, Australia, was intended to be the 247’s moment of glory. Race ace Roscoe Turner leased a 247D from United and entered the contest with Clyde Pangborn as his copilot. Turner filled the airplane’s cabin with eight “Turner tanks” of extra gasoline to cut down on refueling stops. Of the 20 other entrants, De Havilland entered several of its achingly beautiful pure racers, the twin-engine Comet, and KLM came to the starting line with a bone-stock Douglas DC-2 filled with three paying passengers riding its normal route to Australia, which included 14 en-route stops.

To nobody’s surprise, a de Havilland Comet was the ultimate winner. To everybody’s surprise, the KLM Douglas and its passengers finished second. The race-prepped Boeing 247D came in third— an awkward also-ran, just as it was in its airline life.

Fortunately for Boeing, the race had two categories: a flat-out, winner-take-all run and a second handicap category based on the entrant’s gross weight, horsepower, wing area, payload and other factors. United chose to enter its 247 in the handicap race, which gave it second place behind the DH Comet race plane, since the KLM DC-2 was entered in the unhandicapped category.

One smart PR move that Boeing and United did make was to underwrite a contest, sponsored by Popular Aviation magazine, to build flying models of the new 247. Some 4,500 sets of free plans were sent to young modelers, some of whom doubtless became future airline pilots. Boeing also cast small metal models of the 247 for employees to buy for $9.15 ($10.45 with working landing gear). Considering that it was the depth of the Great Depression and that those price tags were equivalent to over $200 today, we can safely assume they sat only on executive desks.

Boeing apologists often blame the 247’s failure as a viable airliner on the fact that its wing spar stretched across the cabin, creating a shin-banging obstacle for passengers. In fact, the wing’s main spar formed a low barrier between the passenger cabin and the flight deck, so its obtrusiveness would only have been apparent to the captain and first officer, who were paid to step over spars. The smaller secondary spar, which ran under the fourth row of passenger seats with a step to aid passage, would have been a minor inconvenience. Though perhaps not to the stewardesses who feared tripping on it while carrying a tray of coffee. But stewardesses didn’t doom airliner designs. A more likely theory? It’s a convenient myth.

United began phasing out its 247s in 1934, as TWA DC-2s stole much of its traffic. Many went to smaller airlines that served as feeders for United’s main routes. Some served in the U.S. Army Air Forces and the Royal Canadian Air Force as C-73 multi-engine trainers and transports. One went to the Royal Air Force for use as a radar and electronics testbed, and in January 1945, it established the final entry on the 247’s making-history page by flying the first ever fully automatic blind landing.

One of the last passenger-carrying 247s was the “Reno Champagne Cruiser,” a pink-painted party bus that for two years in the mid-1950s flew the 65 miles between Washington, D.C., and Colonial Beach, Virginia, typically carrying legislators and their girlfriends to the semi-legal casinos in the Virginia town.

What a way to go.

This article originally appeared in the Spring 2023 issue of Aviation History.