The Pratt & Whitney R-2800 was the most remarkable piston aircraft engine ever built. This compact 18-cylinder, twin-row radial powered a huge number of World War II fighters, bombers and cargo planes, then went on to propel fleets of 1950s airliners. Seventy-three years after the first R-2800 cranked, wheezed, chuffed, puffed and fired, cylinder after cylinder slowly awakening in the classic radial pattern, oil smoke whirling aft all aflutter, rebuilt R-2800s are still in constant demand among warbird collectors.

“Most remarkable” engine? How dare I. How about the minivan-size, double-crankshaft Napier Sabres and their strange sleeve-valve arrangements? And what about the 36-cylinder Lycoming XR-7755, at 127 liters displacement the biggest piston aircraft engine ever built? (Larger radials exist, but they are for marine use.) Or Chrysler’s Lycoming competitor in the hyper-engine experimental program, the 16-cylinder inverted-vee IV-2220? How about the super-powerful Wright R-3350 turbocompounds, their exhaust-driven blowers geared directly back to the crankshaft? Or the four-row Pratt R-4360 “corncobs,” so nicknamed because they had as many cylinders as a country fair ear has kernels? And certainly Rolls-Royce Merlin fans are hyperventilating if they’re reading this, for the Merlin was the Colombo Ferrari V12 of aircraft engines.

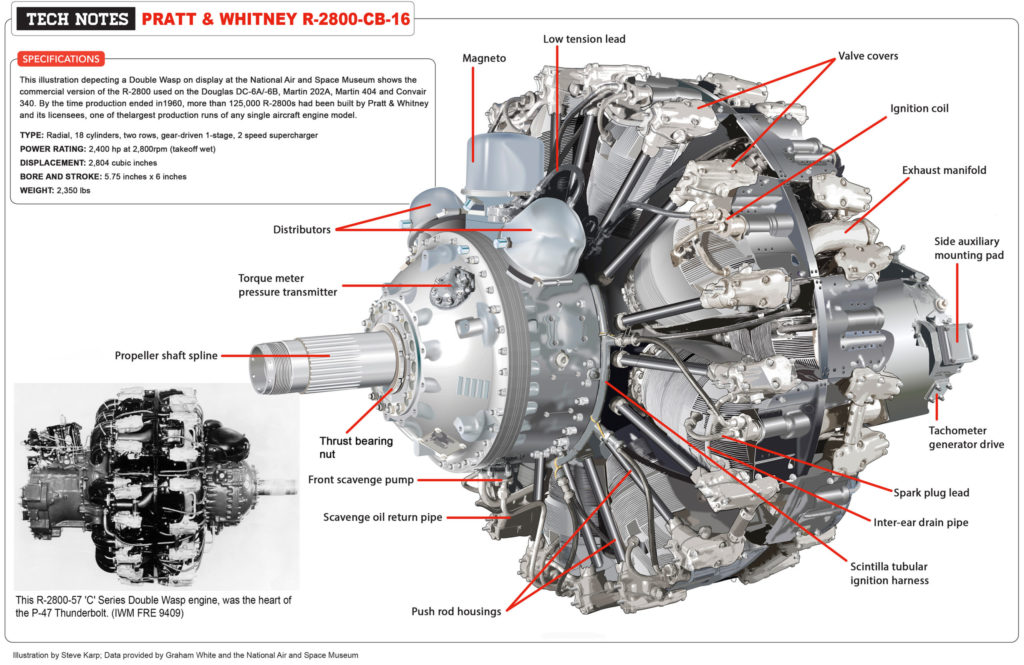

Yes, but the R-2800 was the Chevy Small – block V8 of aviation. The Merlin had cachet, exclusivity and a wonderful exhaust note. But like the automotive Smallblock, the Pratt & Whitney offered comparative simplicity and economy while producing horsepower far beyond what it deserved. Though you’ll see fanciful claims of as much as 2,800 horsepower, the most powerful variants of the R-2800 that went into production cranked out 2,500 hp at takeoff power, according to piston-engine expert Graham White’s authoritative book R-2800: Pratt & Whitney’s Dependable Masterpiece. Tuned for air racing, some reliably put out 3,000 hp.

Too bad the Reno racers didn’t have the help of Pratt & Whitney’s engineers. When during the early years of World War II the company began work on the 28-cylinder corncob, the team that developed the R-2800 kept competitively boosting the power of its test engines to 3,000 hp, and then 3,500 and ultimately 3,800 hp with the help of water injection (to cool the intake charge) and stratospheric amounts of supercharging. The R-4360, however, eventually went on to produce a semi-reliable 4,300 hp.

The R-2800 deserves the “most remarkable” superlative not because it was the most powerful, or had the best power-to-weight ratio, or used advanced materials, or had the trickiest technology or the most cylinders or biggest displacement. No, like the classic Smallblock, the R-2800 provided a fabulous combination of truly useful characteristics.

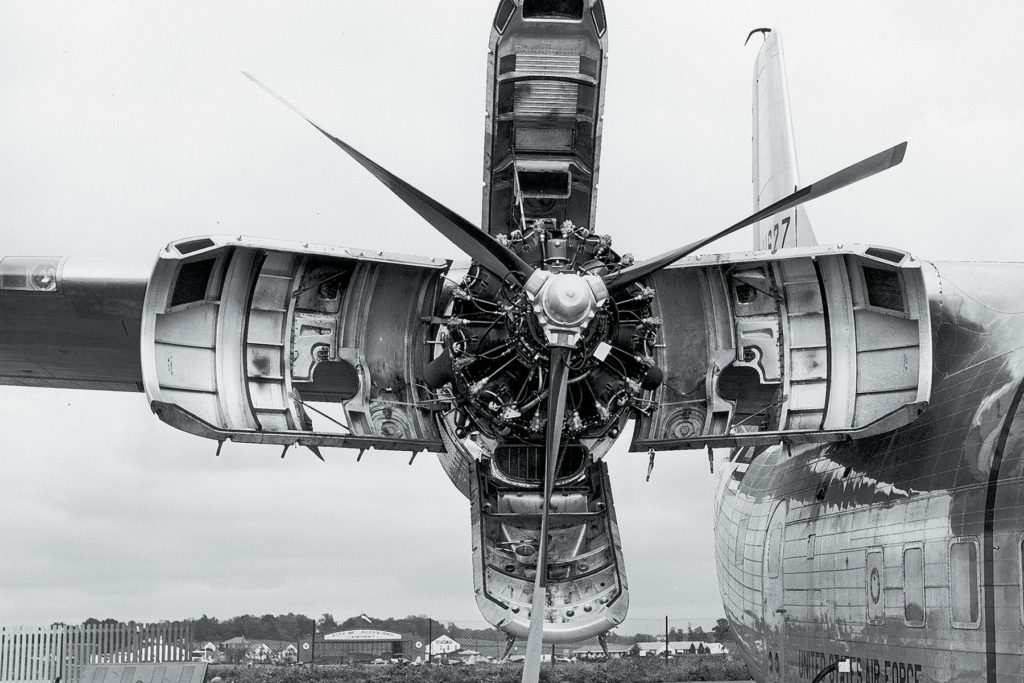

It had very little “installation drag”—drag produced by the frontal area of an engine plus the need to push cooling air through it, or in the case of liquid-cooled engines, through their radiators. The R-2800 could be tightly cowled, and cooling air was channeled through its thin, complex and precise cylinder fins by tight-fitting “engine tin”—baffles that cupped the rear of each cylinder.

In postwar Convair 240/340/440 twin-engine airliners, R-2800s didn’t even need cowl flaps, one of the few production examples of such a high-powered engine being able to do away with those troublesome drag-producing and workload-adding doors and gills. At takeoff power, a late-model R-2800 needed to rid itself of 10,000 BTUs a minute. This is a major challenge, and Convair designed augmenter exhausts to accomplish it: The R-2800’s substantial exhaust energy was piped into big horizontal-chimney ducts at the rear of each nacelle, and the rush of hot air through them pulled cooling air into and through the forward part of the nacelle.

The R-2800 had an excellent power-to-weight ratio, low specific fuel consumption— pounds of fuel burned per horsepower per hour—and a long working life before it needed to be overhauled. It was easy to work on, superbly reliable and cheap, at least compared to a liquid-cooled Merlin or Allison or more complex radial engines. There was no single area where the R-2800 was the absolute best, but its combination of qualities made it the overall winner.

The R-2800—R for radial, 2800 its swept volume in cubic inches (2,804, to be exact), meaning that each of its the 18 cylinders displaced as much as an entire Subaru Outback engine—was also, in civilian use, called the Double Wasp. The Wasp R-1340 had been Pratt & Whitney’s very first engine, a single-row, 9-cylinder radial. Pratt & Whitney had initially designed its big twin-row radial as, roughly speaking, two Wasps sandwiched together, but this produced an R-2600. The competition, Wright Aeronautical, already had an R-2600 under development, so Pratt upped the displacement of each cylinder by just over 11 cubic inches, and the result, in 1937,was the first R-2800. (Confusingly, Pratt & Whitney also made a double-row radial it called the Twin Wasp, an R-1830.)

The U.S. Navy was Pratt’s biggest booster, since carrier aviators wanted nothing to do with what they saw as unnecessarily complex and vulnerable liquid-cooled engines. Though the name of the naval officer who said it has been lost to history, he’s often quoted. “A water-cooled aircraft engine,” he opined, “makes as much sense as an air-cooled submarine.” What he meant, of course, was that airplanes lived in the air, so why not use that medium for cooling? A liquid-cooled engine could be put out of business by a single coolant leak, whether caused by enemy fire or a simple hose, line or seal failure, and this was something nobody flying over an ocean wanted to contemplate. Naval aircraft engines also had to be maintained aboard a ship, with limited repair-and-replace options, and fiddly engines that required factory maintenance had no place in an aircraft carrier’s hangar deck.

“Factory maintenance” is no exaggeration in the case of some liquid-cooled mills: The Luftwaffe’s prime mover, the Daimler-Benz DB 601 inverted V12, was designed to be easily removed from Messerschmitts and the like as a complete firewall-forward unit and re – turned to the factory for whatever work might be necessary. Kids in flip-brim baseball caps standing on 55-gallon oil drums—the typical U.S. Army Air Forces “technicians” during WWII—wouldn’t have been allowed to touch the DB 601; you needed a clean white shop coat and a clipboard to qualify.

The core, literally, of a powerful radial engine like the R-2800 is its crank- shaft, and the crank was a continuing weakness during that power plant’s early development. The problem was torsional vibration: Every time one of the huge cylinders fired, its connecting rod would whack its crank journal, causing the entire crankshaft to twist a tiny amount, tens of thousands of times per minute. Ultimately the crankshaft would fail due to fatigue. Graham White describes one such ground test failure in his book:

A rear crank cheek failed. At the time of failure the engine was running at takeoff power. The failure immediately locked the engine solid… and the engine tore itself off the mount, and rotated in the test cell until the [protruding] carburetor stopped its rotation. The propeller, in the meantime, tore itself loose and continued to slam itself against the walls of the test house. When everything had settled down, the scene was that of utter destruction.

It took nearly four years of testing, from January 1938 through October 1942, before Pratt came up with a crankshaft that would succeed. The solution was a combination of metallurgy improvements and a pair of second-order counterweights rotating at twice the speed of the crankshaft, to cancel out the energy surges of the firing pistons.

In later years, R-2800s became legendary for surviving damage that would have stopped a Merlin or an Allison like a stake through its heart. Many pilots came back from missions knowing their R-2800 was down on power but still running relatively smoothly, with no cockpit gauge indication of an anomaly. In some cases it wasn’t until a crew chief pointed out a blown cylinder head and barrel, sometimes literally sitting in the bottom of the nacelle, that the pilot realized he’d been flying a 17-cylinder engine.

The R-2800 had a straightforward but sophisticated combustion chamber design: just two huge valves and a strongly round-roofed cylinder head—what came to be called a “hemi” when Chrysler began marketing the term for its most powerful automotive V8s. The valves were sodium-filled, which was novel when the R-2800 was being developed. The valve stems were hollow, and liquid sodium sloshed back and forth through the stems as the valve clattered in and out, thus constantly carrying heat from the superhot head to the cooler valve-guide area and thence to the finned cylinder head. It was another reason the R-2800 was so good at dissipating the heat it generated.

The R-2800 had two spark plugs per cylinder. Modern-day lightplane pilots invariably will explain that this is so an engine can continue to run even if one of its two magnetos fails. In the case of the R-2800 and other big-bore engines with high cylinder pressures— the R-2800 had a low compression ratio of 6.65-to-1, but supercharging or turbocharging raised combustion chamber pressures greatly—that’s not true. The two plugs were present in order to properly fire the intake charge completely, all the way across the broad combustion chamber. Failure to do so, which would be the case with just one plug firing, would result in detonation and rapid destruction of the engine. Piston pressure would compress the unburned part of the charge to the point where it would explode— detonate—and rapidly burn a hole through the piston crown.

There are engine fans who love the sound of a P-51’s or a Spitfire’s Merlin starting—tac, tac, tac, tac cranking and then a few pops and pretty quickly a lope of smooth power—but starting an R-2800 is a much grittier symphony, imbued with a kind of primitive, Industrial Revolution simplicity.

“They weren’t hard to start, but they were challenging to start,” recalls Thomas Block, a retired U.S. Airways captain who started his 36-year airline career in the early 1960s as a 19-year-old co-pilot in Mohawk Airlines Convair 240s, 340s and 440s—all powered by pairs of R-2800s. “You always bet a beer on how many backfires you’d get. You played the starting sequence like a piano, with three fingers and the thumb of one hand. There was a boost-pump switch, a starter motor and a primer, and the thumb held down the safety so the three switches would work.

Recommended for you

“The primer you played to get just enough fuel without flooding it. You could get out of sequence, and the engine would just go BANG…BANG…BANG! It didn’t hurt anything, but everybody got a big laugh out of it.” Block recalls that “The way you knew you’d flooded it was that suddenly there’d be fuel pouring out of the bottom of the engine, through the airbox, and the mechanic would look up and yell, ‘Boy, ya got ’er flooded now.’ We always had a big, wheeled fire extinguisher standing by, because it was not unusual to have a ground fire. If you got a backfire through the carburetor, it’d ignite the puddle of gas under the engine. That was always exciting…”

Was the R-2800 a good engine? “Everybody thought it was,” says Block. “We didn’t have turbines to compare it to, but rated against other big recips, it was an excellent engine. Of course, none of them had a fraction of the dependability of turbines. We feathered engines all the time. I had 11 R-2800 failures in my first two years with the airlines, landed on one engine 11 times—far more failures than I had in a variety of turboprops and jets in the next 34 years. It was amazing how you could blow whole jugs off the airplane, and if you pulled the power back, the engine kept running. You knew something was wrong, but you didn’t know exactly what it was—you just weren’t getting full power. And then you’d get on the ground and there’d be two cylinders hanging by their studs in the cowling.”

Block’s most challenging R-2800 failure was a double engine runaway while climbing out of Ogdensburg, N.Y. “We had Curtiss electric props on some of our Convair 240s, and they were nightmares,” he recalls. “The master motor that controlled both props suddenly shorted out internally, and it took both props right through the redline. They sounded like turbines, and the engines were bouncing around in the cowlings.”

The captain—Ed Johnson, a fabled Mohawk pilot and Block’s mentor—who was desperately trying to hand-fly the runaway plane back around for a landing, turned to Tom and yelled, “Kid, do somethin’!” Block finally managed to uncouple one engine from the shorted master motor and feathered it while the other engine’s prop slowly calmed. “We’d gone over every temperature and pressure limit,” Block says. “It was a double-engine, double-prop replacement when we got back on the ground.”

But it was a grand time to be an airline pilot if, like Block, you savored the craft rather than simply the salary. “The R-2800 days were the highlight of my career, in a sense,” Block reminisces—and this is a man who ended his airline days flying Boeing 767 widebodies across the Atlantic. “That’s when flying was fun, and there was a whole lot to engine management—a whole lot. You’d spend hours sitting at the feet of the masters, like Ed Johnson, who understood how to keep these things running, how to get them started and shut down. You might find a cryptic note here and there about operating technique or how to effectively reduce fuel flow, but you couldn’t learn by reading about it, you learned by watching somebody do it, and you passed it on to somebody else.”

Looking back, Block muses: “I enjoyed the art of flying, and a lot of the art was taken away by going from R-2800s to turbines. It was like going from hand-painting to Etch-a-Sketch. If your object was to never have any problems, that was great. I was in the game for the game. Those who were in it for the money all welcomed the change, because it made their work much easier.”

The R-2800s “were good engines, and they were fun to operate, but they did take a lot of technique. But it was technique that made you feel you actually were contributing something rather than being just a name and number on a trip bid. You had to really know what you were doing, or in short order bad things started happening.

“It was not an engine that you could hurt, though. You couldn’t make it fall apart. It fell apart on its own. It didn’t need any help. It would just fall apart when it was time to fall apart. Parts would fall off, but the engine itself would keep going.”

Who could ask anything more of an aircraft engine? R-2800s ruled.

Frequent contributor Stephan Wilkinson is a former executive editor of Flying magazine. For further reading, he recommends Graham White’s R-2800 and Allied Aircraft Piston Engines of World War II, as well as Bill Gunston’s Development of Piston Aero Engines. Also see the Aircraft Engine Historical Society Web site, enginehistory.org.

Originally published in the March 2009 issue of Aviation History. To subscribe, click here.