Penicillin helped win World War II. Peoria made it possible

SERENDIPITY has long been one of medicine’s most steadfast collaborators. Arguably, the most potent example of an influential accident was when Dr. Alexander Fleming returned to his London laboratory after a summer break in 1928 and noticed that mold growing in a petri dish containing Staphylococcus aureus was inhibiting the bacteria’s growth. Fleming wondered if the furry, blue-green lump, later identified as Penicillium notatum, could possibly be a new germicide, and, after further testing, he determined that it was, in fact, an extremely effective antibiotic. None of his colleagues showed much interest, so Fleming immersed himself in other projects.

Almost a decade later, England was bracing for war and British scientists urgently sought new treatments for battlefield infections, which often killed more troops than bombs and bullets combined. Dr. Ernst Chain, a Jewish refugee from Hitler’s Germany who resembled a young Albert Einstein, stumbled by “sheer luck,” he later said, across an article Fleming had published in 1929 and showed it to his boss at Oxford University’s School of Pathology, Dr. Howard Florey. Florey agreed that it warranted more study, and the two men, along with Dr. Norman Heatley and Dr. Margaret Jennings, secured a Rockefeller Foundation grant to research penicillin’s medical applications.

Unable to persuade the British government or private companies to underwrite their efforts, Florey decided he would have to look for a partner outside of war-torn Europe with the resources, manpower and scientific wherewithal to produce this new wonder drug on a massive scale. He knew just who to call—the U.S. Department of Agriculture’s research lab in Peoria, Ill., a Depression-era institute that devised new ways of putting surplus crops to good use. Today it’s known as the National Center for Agricultural Utilization Research (NCAUR), and when I contact them, I’m greeted on the phone by the lovely Scottish voice of Jackie Shepherd: “Good morning, USDA, how may I help you?”

I tell her I am researching NCAUR’s role in manufacturing penicillin after English doctors had discovered it. Jackie verified that, yes, I had the right place, and she then connected me to communications officer Katherine O’Hara to schedule a visit. But before patching me through, Jackie playfully admonished me. “I don’t believe that Fleming was English,” she said, her native lilt sounding stronger than before. “He was a Scotsman.”

When I arrive weeks later at 1815 North University Street, Katherine gives me a packet of penicillin-related materials from NCAUR’s archives. “Here’s what started it all,” she says, pulling out a July 9, 1941, telegram. It’s from Department of Agriculture administrator Dr. Percy Wells to NCAUR director Dr. Orville E. May: “Heatley and Florey of Oxford, England, [are] here to investigate pilot scale production of bacteriostatic material from Fleming’s penicillium in connection with medical defense plans. Can you arrange immediately for shallow pan setup to establish laboratory results in metal [containers].”

Heatley and Florey had landed at LaGuardia Field on July 2 wearing thick wool suits more appropriate for England’s cooler climate than Manhattan’s sweltering heat. But neither man let go of his jacket; smeared into their coat pockets were the “backup” spores they would use in the event that Florey’s briefcase—packed with notebooks and carefully wrapped vials of freeze-dried penicillin—was heisted.

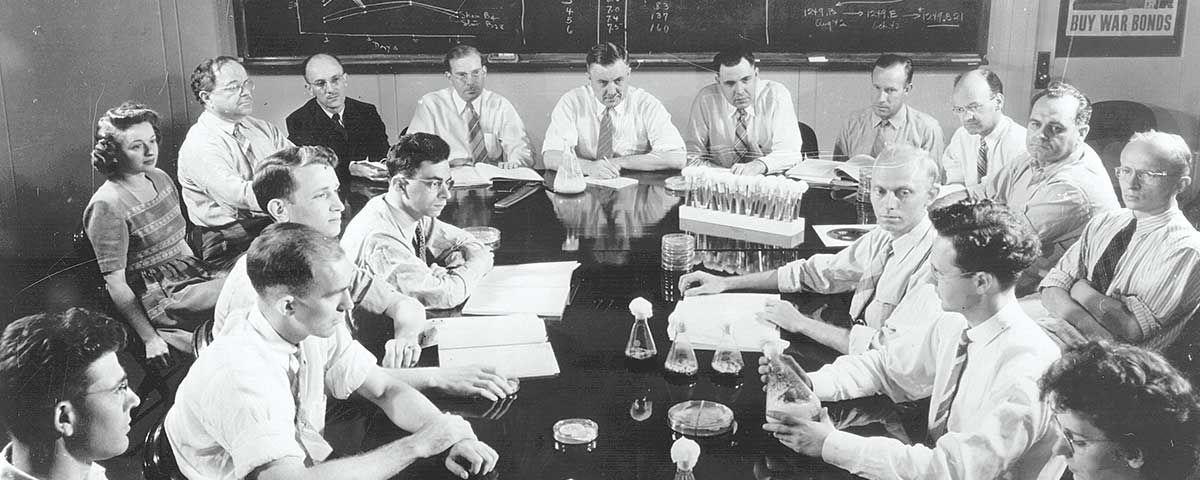

The doctors made their way to Peoria, and on July 14 they met with Dr. Robert Coghill, director of NCAUR’s fermentation division, and Dr. Andrew Moyer, an expert on the nutrition of molds. Within 48 hours, Moyer and his team were hard at work cultivating the samples smuggled over from Oxford. After an initial scare, when the spores that had blossomed so quickly in England didn’t take to the research center’s balmy, 80-plus-degree temperatures (the new air conditioning system wasn’t operational until that September), the Peoria scientists were finally able to grow the first tiny batch of mold by July’s end.

To mass produce penicillin, Moyer first suggested utilizing corn steep liquor in the fermentation process. The idea was as much practical as it was scientific: The thick, syrupy liquid was rich in nitrogen, and it could be acquired easily because nobody wanted the stuff. A byproduct of cornstarch, it was often just dumped by local corn mills into the Illinois River. Adding corn steep liquor alone upped the yield a stunning 1,000 percent. The Peoria crew then experimented with brewing up penicillin in 10,000-gallon vats. Moyer recommended adding lactose to the corn steep liquor and aerating the broth with a constant supply of sterile oxygen to produce penicillin not just on the surface but throughout the culture. This, too, increased yields substantially.

Moyer realized, however, that to maximize results they needed a more resilient mold. Leading the hunt for this new, tougher strain was NCAUR mycologist Kenneth Raper, who instructed members of the U.S. Army Transport Command to bring him mold extracts and soil samples from wherever they traveled around the world.

After working 70-hour weeks sifting through a malodorous array of decaying fruits, old cheeses, breads, meats and clumps of dirt, Raper finally isolated the “super” mold he’d been searching for. Approximately 50 times more potent than anything previously tested, the strain eventually became the primogenitor for almost all of the world’s penicillin. And it was found, by chance, on an overripe cantaloupe purchased at a Peoria grocery store. (The exact location, alas, isn’t recorded. Robert Coghill only noted the source as a “fruit market” near the lab.) The miracle melon itself was neither preserved for posterity nor disposed of with any kind of ceremonial pomp befitting its significance. After cutting the mold off the rind, staff members sliced up the cantaloupe and ate it.

By June 1944, right in time for the D-Day landings at Normandy, drug companies were churning out an estimated 100 billion units of penicillin per month, enough for an estimated 40,000 U.S. and British combatants. Hitler’s forces had to rely on less effective sulfa drugs and, consequently, experienced higher fatality rates, more amputations and longer recovery times for injuries, diminishing their overall troop strength. On and off the battlefield, penicillin cured an ever-expanding range of afflictions—pneumonia, strep throat, gas gangrene, septicemia, spinal meningitis, scarlet fever, puerperal sepsis, to name just a few—and with virtually no side effects, the new drug became as indispensable to the Allied war effort as any weapon.

One of Dr. Moyer’s successors, Dr. Cletus “Clete” Kurtzman, took me on a tour of the laboratories. Clete’s been working at NCAUR for 42 years and oversees a collection of 100,000 different microbes. He opens the stairwell door to the third floor and we walk into a bright, fluorescent-lit hallway. “All of this has been newly renovated since the 1940s, and even the walls have been offset by the new construction, but Moyer’s lab would have been around here,” he says in front of Room 3118.

We peek inside, and Clete explains that this is where they now store NCAUR’s cultures. “About 80,000 of the microbes are fungi,” he says, “and the other 20,000 are bacteria.” Large, double-door steel refrigerators, like those found in any modern household kitchen, line both sides of the laboratory, and down the middle are liquid nitrogen containers the size of industrial drum barrels.

Clete starts talking about another medical innovation developed during the early 1950s by Dr. Allene Jeanes in the lab right across from Room 3118: dextran, the blood plasma substitute originally intended for U.S. troops fighting on the front lines in Korea. It’s commonly used in hospitals today and has prevented countless patients from bleeding to death.

The lifesaving blood extender was created out of a “slimy bacterium,” Clete tells me, that wasn’t exactly drawn from the lab’s official collection of microbes. Another NCAUR scientist had shown the mold to Dr. Jeanes after spotting it inside a half-empty bottle of old root beer that someone, fortuitously, had neglected to throw away.

If you would like to share a little-known site where history happened, please visit www.HereIsWhere.org.