Inadequate technical information concerning modifications to the fabled F-86 led to a series of major takeoff accidents.

In the spring of 1953, while I was a U.S. Air Force pilot with the 4th Fighter Interceptor Wing (FIW) in South Korea, the new and improved North American F-86F Sabre began to arrive in fighter units. Along with increased engine thrust and certain aerodynamic modifications came the need to follow new techniques and procedures. Unfortunately, a breakdown in the information flow from North American Aviation (NAA) to the pilots resulted in several major avoidable accidents.

One of the first mishaps occurred on June 24 at Kimpo Air Base (K-14) as the Korean War was winding down when a new F-86F overran the runway during a routine test flight after an engine change. Pilot 1st Lt. Sam Jackson, of the 336th Fighter Interceptor Squadron (FIS), later told accident investigators that during his takeoff roll there were no abnormalities in either the exhaust gas temperature or aircraft acceleration. “At one hundred knots I exerted a slight back pressure on the stick, which normally was sufficient to raise the nose to takeoff attitude,” Jackson said. “Yet there was no change in the relative position of the nose of the aircraft.” After several attempts to lift off—and by then with what should have been plenty of ground speed—he aborted the takeoff and elected to catch the newly installed runway overrun barrier cable (which was later improved and designated the BAK-12 Arresting System).

At the time, K-14’s runway was 6,000 feet long—the shortest jet fighter airstrip in South Korea—and U.S. Army engineers were in the process of constructing extensions at both ends. “I was unaware that earth-moving equipment had been preparing the overrun for resurfacing,” Jackson told the Accident Board. “In addition, there had been heavy rains creating mud and potholes….I slowed somewhat and made a good cable pickup near the centerline of the runway. I saw the nylon tapes fly as I engaged the cable and started off the paved end of the runway.”

As the Sabrejet entered the overrun, however, its nose wheel immediately hit a pothole and snapped off. Simultaneously, the barrier cable broke loose from the anchor chain on the right side, causing the aircraft to cartwheel and shed its wings as the burning fuselage rolled almost upside down in the muddy overrun.

“Burning fuel poured down on me and I was burned everywhere except my hands and feet,” the pilot told investigators. Fortunately a field grade officer and a sergeant were just passing the end of the runway. Using an ax and a knife, they were able to break the canopy, cut Jackson loose and pull him to safety.

In November 1953, again at K-14, 334th FIS pilot Lieutenant Donald Showen was unable to rotate his F-86F for takeoff and was forced to make a high-speed abort. His story was familiar: “I was leading a flight of four. Upon brake release my wingman and I accelerated normally to rotation speed. I then eased back on the stick, but the nose wheel seemed stuck to the runway….Then I aimed for the middle of the runway and took the runway overrun barrier in textbook fashion. The barrier cable caught my main landing gear; and, except for some bent landing gear door fairings, there was no damage—other than to my ego.”

Thanks to the newly paved overrun, Showen’s abort was a textbook example of the benefits of the arresting system in preventing rejected-takeoff accidents. Still, the reason why the aircraft failed to rotate to a takeoff attitude could not be explained. Consequently, the newly appointed flight commander was demoted to line pilot.

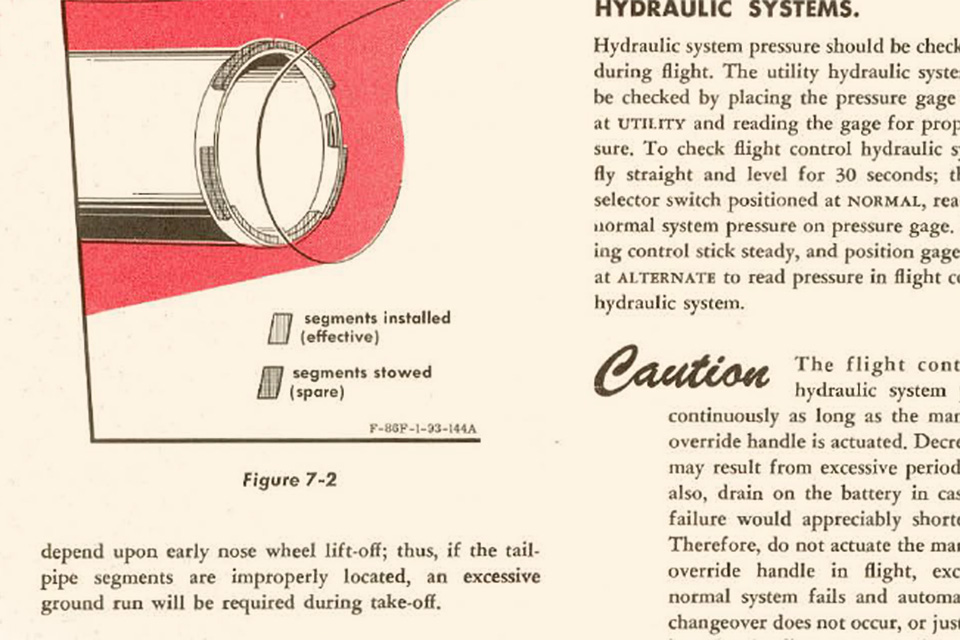

Because the upgraded General Electric J47 turbojet installed on new F-86Fs was equipped with a fixed-area tail pipe, the combination of engine RPM and exhaust gas temperature (EGT) was used to provide a direct indication of thrust output. At 100 percent RPM, the tail-pipe temperature had to be 690 degrees Celsius for the engine to produce maximum rated thrust. If the EGT was low, the tail-pipe diameter needed to be slightly reduced. This was accomplished by an Air Force engine technician installing one or more metal segments—universally referred to as “rats”—on the inside lip of the tail pipe. Each segment would slightly increase the turbine discharge pressure, which in turn increased the EGT. Still, what the technicians and pilots often didn’t realize was that the precise location of the segments on the tail-pipe lip was critical to a successful takeoff.

North American later had an explanation added to the pilot’s Dash-1 (operator’s manual). It stated that the tail-pipe segments were needed to “adjust the exhaust outlet area to produce as near as possible a stabilized exhaust gas temperature of 690 degrees C at 100% rpm during ground run-up….The initial segments are installed at the bottom of the tail pipe. As additional segments are needed, they are installed as symmetrically as possible, starting from the bottom of the tail pipe [emphasis added]. Initial segment installation beginning at the top of the tail pipe is not recommended, because it will reduce the down-tail load. Down-tail loading aids nose wheel lift-off and is a reaction caused from the tendency of the jet exhaust stream to cling to the upper fairing shelf aft of the tail pipe….Whenever this down-tail loading is reduced or lost, nose wheel lift-off speed will increase substantially….[T]hus, if the tail-pipe segments are improperly located, an excessive ground run will be required for take-off.” Although clearly an understatement considering that experienced pilots had been unable to get their F-86F to rotate for takeoff at any speed, this information resolved the problem and the accidents stopped.

The Accident Board investigating Lieutenant Jackson’s crash had at first blamed it on pilot error, but with the new information provided by NAA regarding improper placement of the engine tail-pipe segments, the reason for his mishap was changed to “cause unknown.”

A second modification that caused several accidents involved the new extended-leading-edge wing on the F-86F-30. Although the Sabre’s aerodynamically operated leading-edge wing slats had proved beneficial in the takeoff and landing phase, during high-altitude encounters with MiG-15s they were problematic, as they caused early pre-stall buffet with an accompanying instant loss of airspeed. To correct this deficiency, NAA test pilots suggested replacing the leading-edge slats with fixed extensions. This, they theorized, would lower the pre-stall buffet boundary at high altitudes and concurrently decrease the airplane’s turning radius. Thus, in August 1952, project engineers removed the leading-edge slats from three Sabres and perfected the extended-leading-edge modification (also installing a wing fence).

Total wing area was increased from 287.9 to 302.3 square feet, with the aerodynamic slats replaced by 6-inch extensions at the wing root, tapering to 3 inches at the wing tip—the so-called “6-3” extended wing. At high altitude the new wing design worked perfectly. Now pilots could cruise comfortably at 49,000 feet and .9 Mach.

Yet the new 6-3 extended-wing Sabres were quickly plagued by takeoff accidents. And, as with the tail-pipe mods, the problem was traced to a lack of information.

During the early spring of 1953, when the first 6-3 wing Sabres began to arrive at K-14, onsite NAA technical representatives had verbally advised the 4th FIW pilots of an increase in the new aircraft’s stall speed. This required an approximate 20-knot increase in the aircraft’s takeoff and landing airspeeds.

On the west side of K-14, the 67th Tactical Reconnaissance Wing had received its first camera-equipped RF-86A in late 1952. Because the 67th TRW was equipped with Lockheed RF-80s, its lone Sabrejet was temporarily based with the 334th FIS for logistic support. The airplane’s sole pilot, 1st Lt. Elliott B. “Jack” Sartain, even bunked with us 334th pilots.

Then, in April 1953, a new extended-wing RF-86F-30 arrived, and Lieutenant Sartain and the two camera-equipped Sabres were relocated across the field to the 15th Tactical Reconnaissance Squadron. However, lacking a factory technical representative, the 15th TRS was out of the NAA information loop. Because the pilot’s Dash-1 showed no airspeed changes, the squadron’s pilots and leadership were unaware of their new Sabre’s increased takeoff and landing speeds. Thus, on June 3, they had the dubious distinction of suffering one of the first extended-wing Sabrejet takeoff accidents.

It was the first photorecon combat mission for the new RF-86F, and Sartain was scheduled as wingman to flight leader Captain James H. Howell Jr., who would fly the squadron’s wing-slat-equipped RF-86A. Captain Howell’s Sabre had two 120-gallon wing pylon tanks, while Sartain’s RF-86F was fitted with 200-gallon tanks. In an effort to keep the fuel load equal, the squadron’s maintenance officer had serviced Sartain’s airplane with a partial load of 120 gallons in each of the two pylon tanks.

At 1555 hours Howell and Sartain taxied for takeoff. Both pilots lined up on the runway, increased power to 100 percent RPM and simultaneously released brakes and began their takeoff roll. As he accelerated through 100 knots, Howell rotated the nose of his aircraft for liftoff and shortly thereafter became airborne.

Those of us who witnessed the incident saw Sartain become airborne approximately halfway down the runway, in an extremely nose-high attitude. The Air Force accident report stated, “The aircraft climbed to approximately five feet in the air and continued down the runway without gaining altitude or an appreciable increase in airspeed.” The problem was referred to as “getting behind the power curve”—lifting off too close to the airplane’s stall speed, which created aerodynamic drag that exceeded the available engine thrust.

At the far end of the runway, Army engineers were busily extending K-14’s 6,000-foot airstrip to a more usable 12,000 feet. Consequently, the work area was congested with heavy equipment, and numerous Army and some Air Force civil engineering personnel were pouring concrete into the framed outline of the runway extension.

Upon reaching the end of the runway, the struggling Sabre clipped the right overrun barrier stanchion. Then, still in an extreme nose-high attitude, it continued for another 1,000 feet, hit the blade of a 13.5-ton “Tourneaudozer” and exploded like a giant napalm bomb. Sartain and four Army engineers were killed, and several soldiers were severely burned.

Meanwhile, on the east side of the field, in the 4th FIW combat operations auditorium, a meeting was in progress. NAA chief test pilot Bob Hoover was explaining to a gathering of F-86 pilots the abnormal takeoff characteristics of the extended-wing Sabrejet. At 1540, just 15 minutes prior to Sartain’s conflagration, the 67th TRW had received notification of this critically important meeting.

Worse yet, tests showed that on takeoff roll with the 200-gallon wing pylon tanks only partially filled, the fuel pooled in the back of the tanks as the aircraft accelerated. The weight of that fuel put the airplane aft of its center-of-gravity limitation. This exacerbated the Sabre’s abnormally nose-high attitude and contributed directly to Sartain’s inability to recover. That information had also been omitted from both the maintenance manual and the pilot’s Dash-1.

In the ensuing investigation, the Accident Board was blunt in its findings and recommendations, placing the cause squarely on Air Material Command. The board noted that the pilot’s manual had been published without any information on the changed characteristics of the extended-wing airplanes. This had led the 15th TRS to schedule an extended-wing Sabre to fly the wing of a slat-equipped aircraft. Meanwhile, the same type of accidents began occurring throughout the Air Force—and pilots became afraid of the airplane.

Yet, with the information finally published, the pilots now fully understood the modified Sabre’s characteristics. The accidents stopped and the aircraft went on to become the most widely used Western-produced jet fighter in the world. Ultimately it was adopted by 25 nations, five of which—Canada, Japan, Spain, Italy and Australia—manufactured their own aircraft. Once the Sabrejet’s secrets were uncovered, it became one of the few jet fighters with no bad habits, and was revered by everyone who flew it.

John Lowery served with the 334th Fighter Interceptor Squadron at K-14 in 1953. He finished his Air Force career as a lieutenant colonel with 1,000 hours in the F-86A, E and F. Since retiring he has authored 13 books, including Life in the Wild Blue Yonder, which is recommended for further reading, along with The North American Sabre, by Ray Wagner.

This feature originally appeared in the May 2019 issue of Aviation History. Subscribe here!