If you were a hotshot airplane designer at Boeing in 1965, there was only one place you wanted to be. The aerodynamicists, the airframe designers, the systems engineers, the payload specialists, the engine experts…the project they most coveted was the sexiest thing the company had ever dreamed up: the first American supersonic transport (SST), the Boeing 2707. This was the future of commercial aviation—a true world-shrinker, boasting triple the speed of subsonic jets.

There was, however, another jet taking shape at Boeing at the same time. The document that set out the objectives for this airplane described “a high capacity, long range commercial transport…adaptable to passenger-cargo or all-cargo configurations.”

The model number was 747. Compared with the 2707 it seemed so boring that the SST guys would tease the 747 guys that if they proved their chops they might be lucky enough to be promoted to the faster-than-sound realm.

Guess who had the last laugh. Boeing’s SST never materialized beyond a full-size wooden mockup. Its huge cost and thirst for fuel made it commercially unviable, and the project was canceled in 1971. Boeing sold the mockup, which had cost $12 million, to a fairground in Florida for $43,000.

The 747 grew out of a deal made between Boeing chairman Bill Allen and Juan Trippe, the imperious founder and boss of Pan American Airways. Not so much a deal—more of a handshake agreement made on a yacht during a weekend of relaxation.

Trippe believed the future of commercial aviation would be supersonic, but he thought some time would pass before that became a reality. In the meantime he needed a stopgap, an airliner more than double the size of the Boeing 707 that could be operated at a significantly lower cost. He told Allen that when its time was done the airplane could revert to being all-cargo, a Mack truck of the air.

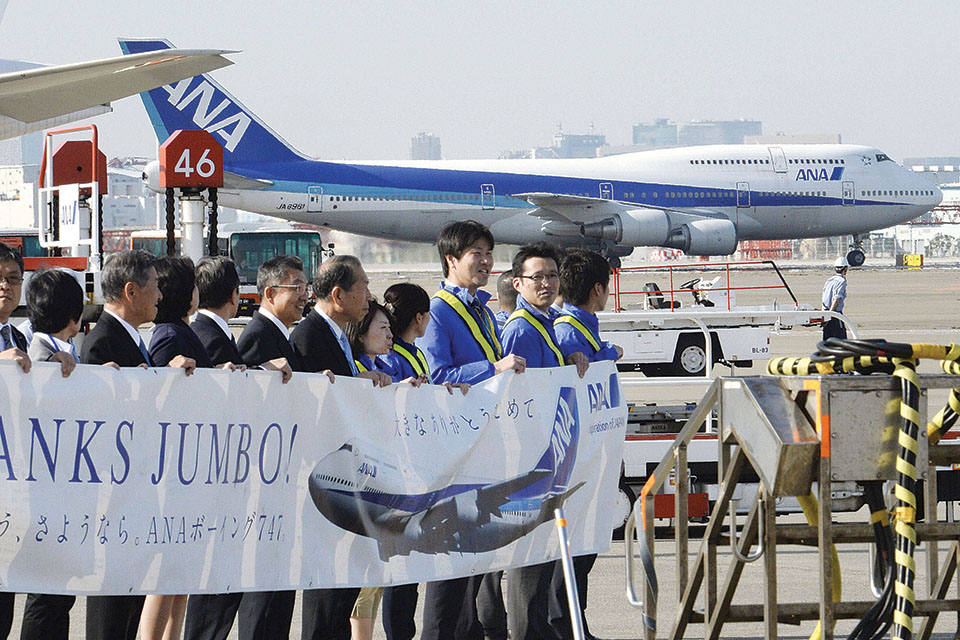

Now, nearly 50 years after the airplane entered service, the last two U.S. airlines to operate 747s have retired them, and elsewhere they are slowly being phased out of passenger service. During that half century no other airplane has had quite the same influence on the world. It was the first jet to truly democratize air travel. Crucially, it inaugurated a universal phenomenon, the enabling of many millions of people to travel around the globe with an ease and economy that was quite new in the human experience.

In the summer of 1965, there was no such arching vision in the mind of Joe Sutter when Allen assigned him to be the chief engineer on the 747 program. Sutter had missed being drafted to the SST team because he was fixing early problems on the 737, an airplane he had partly fathered with a more senior designer, Jack Steiner.

Sutter, an aerodynamicist, was left to scrounge what talent he could to create an airliner whose only innovation was its size. Otherwise, so the theory went, it would be capable of safely flying within the subsonic envelope already familiar to Boeing through its experience with the 707. Sutter, however, saw that size was going to be the real challenge—in the mastery of structure, payload, control and the engines, the first high-bypass turbines, which were at that point completely untested.

In any program of the 747’s size and complexity, there are always critical points where if the wrong call is made the whole project can unravel. In the case of the 747 there were three fateful moments when, as much by instinct as by science, the right calls were made, and all by different people.

The first was by a low-profile engineer, Rowland “Row” Brown, head of the configuration group, who should by rights be credited as the true father of the world’s first widebody airplane.

Trippe had assumed that the most efficient way of seating 400 passengers was simply to stack one single-aisle cabin on top of another, creating a double-decker. The first Boeing drawings for the 747 did just that, but Sutter instinctively resisted the idea. One of his main concerns was the evacuation of passengers from the top deck in an emergency; another was that the cargo hold was too small in relation to the airplane’s size.

In one stroke Brown solved both issues for Sutter. After looking at scores of configurations, he placed two standard cargo pallets side by side and drew a circle around them. This produced a cavernous cargo hold and a main deck nearly 20 feet wide. To handle the evacuation problem he drew two aisles. Like many flashes of genius, Brown’s widebody cabin looked obviously right once it was conceived.

The hump of the upper deck that became so much an expression of the 747’s profile was created to anticipate its final role as an all-cargo transport, with a nose that opened for loading and a flight deck above. With successive models that upper deck has been extended to cover almost half the length of the lower deck.

In 1990, while researching the airplane’s history for a book, I interviewed more than a score of the engineers who led the 747 program. Brown was the only one of them who declined my request to talk. He was, Sutter explained, an innately private man. Sutter himself was no shrinking violet, but he never tried to obscure the importance of Brown to the team he led.

The other two consequential decisions came from interventions made from outside the team.

The first was by Trippe himself. Once he accepted that he wasn’t going to get the double-decker, he told Sutter that every airplane he had ever bought from Boeing had turned out to be too small in its first iteration. Even though the 747 drawings were close to being finalized by then, he demanded that the fuselage be extended by 80 inches, adding three rows of seats in the cabin. Despite the fact that this added 7,500 pounds to the airplane when weight had become critical, Sutter obliged.

The second was by the man most revered by the Boeing engineers, the company’s legendary Ed Wells. As a young prodigy, Wells had designed the B-17 and later conceived the idea, decisive in settling the form of the sweptwing jet, of hanging the engines on pylons beneath the wings. Like Trippe he sensed that the 747 could later be stretched, so he told Sutter to increase the wing area from 5,200 square feet to 5,500 square feet. Lightening the wing loading not only allowed the stretch, it made the 747 a notably easy airplane to land without sacrificing its high cruise speed of Mach 0.855.

Nonetheless, the most serious structural problem to surface was in the wing. An old maxim at Boeing was “the wing is where you’re going to fail.” This was, as Sutter told me, “a big, limber airplane,” and in the wind tunnel the wing turned out to be a bit too limber when, at high speed, the nose suddenly pitched upward.

Sutter called in W.T. Hamilton, Boeing’s doyen of wing design. Hamilton confirmed Sutter’s fear that the only cure was to redesign the wing with a decreasing angle of attack on the outboard section. A complete redesign at that stage would have set back the program by as much as a year. Hamilton came up with a much easier solution: Make a barely perceptible break in the leading edge at the outboard engine pylon and “twist” the wing from there to the tip. It was not an elegant solution, but wind tunnel tests confirmed it cured the problem.

Early flight testing encountered another serious wing defect: flutter. Chief test pilot Jack Waddell reported in his laconic way “low damping.” The wing shook and would not settle. Again the fix was inelegant but simple: 700 pounds of spent uranium ballast added to the outer engine nacelles effectively damped the flutter.

But the most troublesome innovation throughout the 747’s development and its early airline service was the Pratt & Whitney JT-9 engine. General Electric pioneered the high-bypass turbine with its signature big fan, but Boeing had a long and happy history with Pratt and went with them, even though the JT-9 had no military background behind it, as had all the jet engines previously chosen for new airliners. The first engines were plagued with reliability issues and fell short of the promised 40,000-pound thrust. For the 747’s first flight, on February 9, 1969, Boeing went through 30 engines before they found four that were deemed fit.

The troubles continued. As the first production models rolled out, people joked that Boeing was assembling a fleet of the largest gliders in the world because so many were parked awaiting engines. Altogether, 87 engines were used in flight testing and 60 of them were destroyed. There were so many changes to the JT-9 specifications that some test airplanes flew with several different versions. After a short time in flight the turbine casings were susceptible to ovalization, jeopardizing the clearances for the turbine blades. As a desperate temporary fix for the shortfall in power, the engines on the first batch of 747s delivered to Pan Am were equipped with water injection to boost thrust for takeoff.

In January 1970, the first flight of a Pan Am 747 took place when Clipper Constitution departed from New York’s Kennedy Airport for London with 324 passengers…after a seven-hour delay and an airplane switch because of engine problems. (I made my first flight on a 747 operated by TWA in the summer of 1970, from London to Los Angeles. It was two hours late departing, and we had an unplanned four-hour stopover in Seattle for engine maintenance.)

Once those problems were resolved, however, the 747 met Trippe’s target of drastically reducing the number on which the whole project was based, the cost per available seat mile (calculated by multiplying the number of available seats on a flight by the miles flown, and then dividing the operating costs by that number). Pan Am told Boeing that its 747s were achieving a cost of 6.6 cents per seat mile—one third of the 707’s cost.

It was a game-changing achievement that first foretold, for the airlines, the transformative economic impact of widebody jets. And all this had been done while up against a deadline that today seems extraordinary. The 747 program was given the green light on April 12, 1966, when Pan Am signed up for the first 25 airplanes. Sutter issued the detailed specification to the heads of manufacturing that September. In little more than four years a radically new airplane, with equally innovative engines, had gone from paper to regular airline service.

But, in truth, Boeing had bet its future on creating a market that had not previously existed. And doing so brought it to the brink of bankruptcy. At the peak of the program, Sutter had been spending $5 million a day. By Christmas 1969 the company was so deeply in the red that $100 million had to be slashed from the operating costs. Over the next 18 months, 60,000 jobs were cut. Seattle’s unemployment rate jumped to 17 percent, leading to a billboard that became legendary: “Will the last person leaving Seattle turn out the lights.”

Yet Boeing came out of the crisis a leaner and smarter company. It had the jumbo jet market to itself until the arrival of the Airbus A380 in 2005. When the latest model, the 747-8, comes to the end of its production run (it has sold slowly), Boeing will have produced more than 1,550 747s, way beyond what its creators imagined possible.

Sutter was only 44 when he took charge of the program. Many of his team were at least 10 years older. I first met him 20 years later when he had become, as Ed Wells had been, a revered company elder who was asked to cast his eye over all the later iterations of the 747 and any other program that would benefit from his wisdom. He revealed that there had been a critical moment during the 747’s development when his whole career hung in the balance. The corporate cost-cutters descended on him in the middle of the design process and demanded that he cut several hundred engineers from his staff. Sutter refused and defiantly said he needed 800 more. He went home and told his wife he expected to be fired the next day.

He got the additional engineers. From that moment on, nobody doubted that Sutter, a compact and implacable man, ran the show. In 2011, when I saw him again during a visit to see the 747-8 being produced, he quipped, “I had a lot of fun spending all that Boeing money.”

One of the 747’s characteristics that Sutter did not anticipate was its self-cushioning float to the runway in the final seconds of landing. Ground effect, with the downdraft compressed between the machine and the tarmac, was pronounced and benign. Even with a new wing, the 747-8 behaves the same way. “It still has that characteristic of landing itself,” Sutter said. “I didn’t know it was going to turn out that way.”

Designed before fly-by-wire took the visceral contact out of the cockpit, the 747 has always been a pilot’s airplane. Boeing pilot Tom Imrich, who has flown versions of the 747 from the very first one, test airplane RA001, through the 400 series and then as co-captain on the first flight of the 747-8, told me: “Every time I had the chance to take one airborne, or to test it to its limits, and often beyond, it was uniquely special. It will always stand alone for its grace, beauty, agility, strength, speed and faithful response.

“It rode out the worst of turbulence exceedingly well, coped with hellacious winds, safely negotiated the worst of monsoons, edges of typhoons, blizzards, icing, fog and thunderstorms. Forced to fly against its will at very low airspeeds approaching a stall, it would clearly talk back to you, with unmistakable feedback, warning you not to go any further. Forced to fly beyond its Mach limits it was steady as a rock.”

Until the 400 series, launched in 1989, the 747 had a “clockwork” analog cockpit with more than 360 instruments and a third flight crew member, the engineer who sat at a side console. The 400 introduced the glass cockpit, two pilots and far greater fuel efficiency. The 747-100 had a range of 5,300 miles. The 400 has a range of 7,670 miles and was by far the largest seller, with 694 delivered before production ended in 2005.

At the peak of its use, there were about 350 747s in the air around the world at any given moment, carrying some 150,000 passengers. Even though U.S. airlines are no longer flying 747s, about 45 of the 747-8 passenger version will be flying well into the 2030s, and British Airways is not retiring its 747-400s until 2024.

Ironically, the seeds of the 747’s obsolescence were of its own making. Its economic efficiency fundamentally changed the way airlines scrutinize the numbers on a newly offered airplane. In the first decade of the jet age, following the introduction of the 707, the payload calculation was simple. The sheer leap in speed and the thrill of the ride were enough. Boeing, Douglas and Lockheed, the principal players, just put into the cabin as many seats as were comfortably possible. The early passengers, the jet set, were mostly well-heeled and prepared to pay premium prices for the privilege.

As flying opened up to millions, the economic equation changed. It involved a more sophisticated combination of seats, range, cargo capacity and fuel efficiency. To an airline executive today, the management of capacity is everything. It is now a refined art that uses a highly complex algorithm and includes price points spread from first class to coach. These numbers virtually design the airplane, single-aisle or widebody, and demand optimal efficiency. As a result the new Boeing 777X, for example, can carry 414 passengers, as many as the 747-400, with only two engines. It can fly as far as 7,600 miles and is 12 percent more fuel efficient than earlier 777s.

But the 777 has been refined to the point where it is so efficient that it is anodyne. It has none of the 747’s character, that great friendly bulbous nose sitting at the gate. When I wrote my first book about the 747, I realized I wasn’t just writing about a machine, but the biography of the machine and its creators: The machine was, in fact, an extension of those men and their core beliefs about airplane design. The first page of Sutter’s specification for the 747, which became known at Boeing as “the Bible,” opened with: “Safety is the prime design objective of the 747 design program; it shall be given first priority in all design decisions. The designer shall insure attainment of this safety objective.”

To this day, when I board a 747 and think about all its details, visible and invisible, I also hear the voices of those who worked on it, performing under relentless pressure and with a vision of what commercial aviation then stood on the threshold of achieving. As Tom Imrich said to me: “It safely and reliably carried millions of people and tons of cargo to all corners of the earth, over all the oceans and both poles. It made the world smaller, affordably brought cultures together and likely fostered the world’s movement toward global peace and stability.”