The P-51 Mustang was fast. Historian Ray Wagner called its last iteration, the 490-mph P-51H, “probably the fastest prop-driven plane actually used in wartime.” The cautious “probably” and “actually used” are significant; like the Focke-Wulf Ta-152, a high-altitude variant of the Fw-190, the H model Mustang arrived very late in World War II and played scarcely any part in the fighting.

The most common P-51 variant was the bubble-canopy D model, for which a speed of 437 mph is usually reported. Partisans of other fighter types may argue that one or another was faster, but the differences among the very fastest types were tactically insignificant. For that matter, it was never the case that every airplane of a given type performed identically. Paint, wear, engine tuning and pilot technique were among many variables that influenced reported speeds, to say nothing of an impulse to exaggeration shared by manufacturers, pilots and governments alike. Whether all Mustangs were faster than all P-47 Thunderbolts or Fw-190s is not only undecidable but also unimportant. The more interesting question today is not whether the Mustang was fast, but why.

The P-51 was conceived early in 1939, when Britain, anticipating war and having ordered more P-40 Warhawks from Curtiss than the company could rapidly produce, approached North American Aviation, from whom they had been buying the AT-6 trainers they called Harvards, with a proposal that NAA set up a second P-40 production line. NAA offered a counterproposal: They would create a new, superior fighter of their own.

Normally the ordering of any new type was a complicated and protracted process involving competitive bidding and haggling over price, characteristics and performance. In this case, something quite different apparently happened. In a Manhattan hotel room the British Purchasing Commission bought a pig in a poke, trusting the say-so of a few executives from North American.

That small group consisted of North American’s president, James “Dutch” Kindelberger; his assistant general manager and right-hand man for technical affairs, J. Leland Atwood; and chief engineer Raymond Rice and preliminary design specialist Edgar Schmued. The British knew and respected Kindelberger and Atwood, and believed them when they said that they could improve upon the P-40. Why? For one thing, the P-40 was based on a 1936 design; it was not hard to believe that something had been learned since then about how to make airplanes perform better.

But some interpersonal theater was likely involved as well. Dutch Kindelberger’s name is seldom mentioned without the word “charismatic” nearby. Tall, slim “Lee” Atwood was patrician and good-looking, with Robert Young’s candid smile and Leslie Howard’s imposing forehead, and he had a strong grasp of technical detail. The German-born Schmued’s Teutonic accent ballasted his utterances with a specious profundity. The British, desperate for help, wanted to be persuaded, and the men from North American were just the ones to do it.

The purchasing committee asked the Americans to obtain from Curtiss copies of blueprints and other technical documentation on the P-40 and the subsequent but abortive XP-46. Curtiss cannot have been pleased by North American’s end run, but they turned over a box of materials quite graciously, Atwood later said, “considering the competitive aspects.” North American paid Curtiss $56,000 for the papers—not a small sum in 1939—and after giving them a quick once-over put them into storage. According to NAA’s chief aerodynamicist Edward Horkey, they were “obsolete and very amateurish and of no help.”

One of the famous facts about the Mustang is that the prototype was designed and built in 102 days. (The finished airframe had to wait 18 days for an engine, and so the time to first flight was a little longer.) Though four months now seems a very short time in which to create an entirely new airplane, aerodynamicist Irving Ashkenas later recalled the pace as unhurried. NAA designers had naturally been thinking about how they would build a fighter if a contract for one ever materialized. Schmued carried in his head the characteristics of an ideal cockpit. The engine type was preordained: the same mediocre 1,140-hp Allison V-12 that powered the P-40. Semi-monocoque aluminum structures were common at the time, and any experienced shop could make short work of their stress analysis and detail design.

The Mustang’s outer dimensions were nearly identical to those of the P-40. The similarity may have been the result of convergent evolution, or perhaps addressed the more practical consideration that the two types might be sharing hangar space and repair bays.

Still, the P-51 differed from the P-40 in several important respects. One was its squared-off wingtips. This now seems a trivial difference, because hardly any airplanes today have rounded tips and we no longer attach any importance to them. But during the 1930s rounded—or rather modified-elliptical—tips were prevalent, and their aerodynamic superiority was an article of faith.

That belief had a scientific foundation of sorts in the fact that the lowest induced drag—the drag due to the production of lift, which is greatest at low speed—is achieved when the distribution of lift across the span of a wing is elliptical. Rounded tips also drew a bit of support from the animal kingdom: Birds and bugs have them. But reality did not comport well with theory. Because the difference between pressures below and above the wing—what we call lift—causes leakage around the tip, reducing the lift there, the actual lift distribution does not match the shape of the wing. A squared-off tip on a slightly tapered wing may actually approach an elliptical lift distribution more closely than a rounded one does. It is also easier to manufacture. North American had the squared-off tips tested in the University of Washington’s wind tunnel, where a lot of Mustang development work was done; their drag proved to be slightly lower than that of rounded ones.

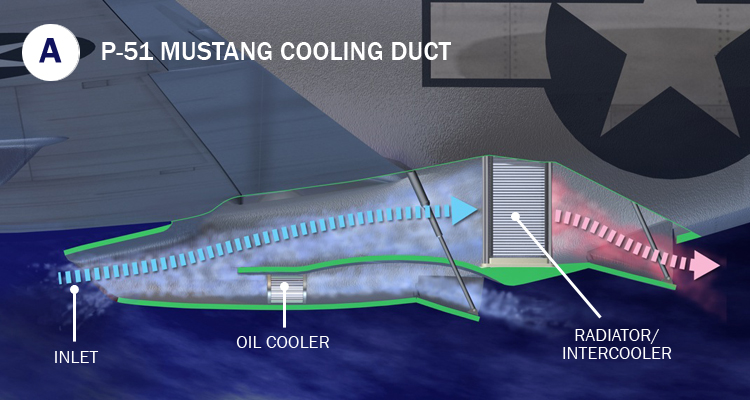

Another difference in the Mustang was the placement of its radiator. Liquid-cooled engines allowed designers to create shapely noses, more aerodynamic and elegant in appearance than the blunt ones of radials, but it was still necessary to get rid of engine heat, and this required a large radiator. The question was, where to put this bulky object without excessively disrupting the aircraft’s aerodynamics?

The P-40’s radiator was slung directly below the engine, where it enjoyed direct blowing from the propeller while on the ground. Spitfires and Me-109s had theirs in the undersides of their wings. P-38s placed them in the tail booms. Mustang designers chose another location, in the fuselage behind the pilot. Bitter controversy would arise about that decision long after the P-51 had retired from active service.

Related to the radiator’s placement was the position of the airscoop that fed it, several feet ahead of the radiator itself. Previous designs had not used such a long entrance duct, nor had they moved the inlet away from the airframe surface, separated by a “boundary layer gutter” whose purpose was to ensure that all the air entering the cooling system was high-energy “free stream” air, uncontaminated by the thin layer of sluggish air that clung to the airplane’s skin.

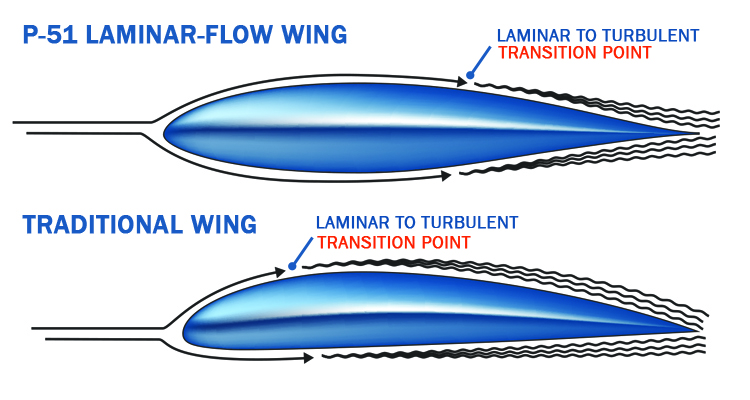

Two other differences were noticeable only to a trained eye. One was the shape of the wing airfoil. Typical airfoils of the time had a relatively blunt, thick leading edge and noticeably more of a bulge on the upper surface than on the lower. The Mustang’s was different. Its leading edge was sharper, and the thickest point was situated almost halfway from the leading to the trailing edge. Behind the thickest point, the surfaces first converged, then subtly changed from convex to concave—an S-shape that came to be called “cusped.”

The lines of the Mustang’s fuselage were more graceful and harmonious than those of most of its contemporaries. The lines were second-degree conics, originally laid out using a graphical method attributed to 17th-century French mathematician and philosopher Blaise Pascal. Schmued said of conics that “this is the kind of shape that air likes to touch,” although he must have known that if that were really the case (even allowing that his language was merely figurative), then the wing profiles should have been developed with conics as well, rather than with the incredibly complex and time-consuming back calculations from desired pressure distributions that NACA computers—at that time a “computer” was a young woman of mathematical bent armed with a Friden electromechanical calculator—in fact used.

Perhaps even more important than the putative benefit of conics was another novelty: extremely careful attention to surface smoothness. The surface quality of the entirely flush-riveted Mustang, demanded by Schmued, was noticeably better than that of previous airplanes.

All these innovations would have remained footnotes in the vast saga of a century’s aeronautical progress but for an article Lee Atwood wrote in 1993.

A civil engineer by education, Atwood had been working for Douglas Aircraft in Los Angeles when he met Kindelberger, who subsequently left Douglas for North American, then located in Maryland, and hired Atwood away from Douglas as well. As Kindelberger’s right-hand man, Atwood provided a bridge between top management and the engineering staff.

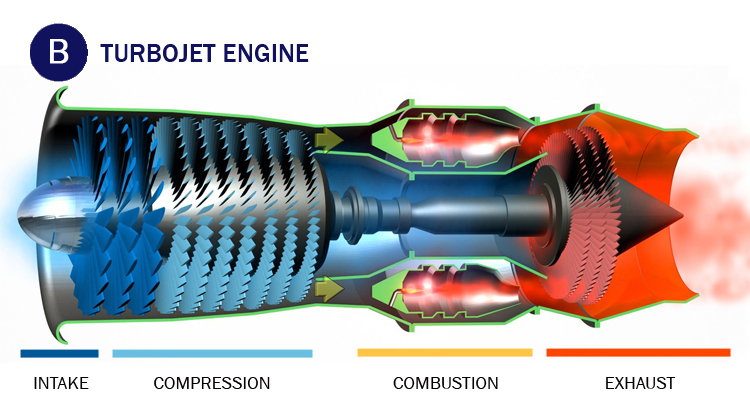

According to Atwood, during those fateful meetings with the British in 1939 he had argued persuasively that cooling drag, a significant portion of the total drag of any piston-engine airplane, could be practically eliminated by astute design of the radiator and its surrounding ducting. Atwood adduced theoretical support from a 1936 paper by F.W. Meredith, a British researcher at the Royal Aircraft Establishment at Farnborough. Meredith’s proposition was essentially that heat energy added to the cooling air by the radiator could be used at high flight speeds to drive the air out through a nozzle-shaped exit at high velocity, producing thrust. In effect, the cooling system would behave like a sort of low-temperature, low-compression jet engine. While Meredith did not claim that a net thrust could be generated, he did assert that at high speeds (considerable ram pressure was needed for the system to work) cooling drag could be greatly reduced, if not altogether eliminated, provided that ducts were correctly designed to minimize losses due to internal friction and turbulence.

Atwood referred to this phenomenon as the “Meredith effect.” Putting it into practice required a rather long duct. The only place you could put such a duct, and even then it would not be ideal, was inside the fuselage. In his article, Atwood in effect claimed credit for the design features most characteristic of the Mustang: the under-fuselage airscoop and the aft location of the radiator.

Atwood’s claim brought a rebuttal from Ed Horkey, who had been chief of the aerodynamic section during the Mustang’s development, in the form of a 1996 article in AAHS Journal titled “The P-51: The Real Story.” The NAA aerodynamicists, Horkey said, knew nothing of the Meredith paper; besides, the thermodynamic principle it described was obvious to anyone versed in the art. The radiator was placed in the aft fuselage because that was the best, and in fact the only, place to put it. In any case, Horkey said, the Mustang’s performance was not due solely to its superior cooling arrangements but at least equally to its laminar-flow wing, smooth surfaces and clean overall shape.

Some sources now give Atwood ultimate credit for the Mustang. Horkey thought otherwise. He believed that Atwood was belatedly trying to burnish his reputation by claiming credit for something that he really had nothing to do with. In a rebuttal to Horkey’s rebuttal, Atwood insisted that “The proposal was…based on the Meredith principle and the cooling system in the fuselage back of the pilot….My instructions to the preliminary design group on this were followed in the very first layout drawing and mockup.” Atwood later conceded, however, in a 1996 letter to George Larson, then editor of Air & Space magazine, that Horkey may “not even have seen [Meredith’s analysis] before the Mustang design work was done.”

Over the years, various myths concerning the Mustang have arisen. One is that Edgar Schmued had previously worked in Germany for Messerschmitt; he had not. Another is that the P-51 cooling system actually did produce a net thrust, a claim that even Schmued himself seems to have made. Neither Atwood nor Horkey went farther than to claim a reduction in cooling drag to only 3 percent of the total drag as opposed to the expected 6 to 10 percent. A 1991 retrospective computational study by David Lednicer and Ian Gilchrist of Analytical Methods Inc. arrived at a similar number, but found that reliable data about the Mustang’s total drag, as well as about its shape and precise dimensions, was extremely hard to come by.

As for the laminar-flow wing, it probably never achieved in practice the very low drag—half that of conventional airfoils of the time—that wind tunnel tests promised. It was simply impossible for a practical-construction metal wing with seams, access panels, gun ports and a factory paint job to be smooth enough to maintain the large areas of laminar flow that appeared on polished wind tunnel models.

It is, in fact, all but impossible to arbitrate competing claims about drag reduction, because it’s so difficult to measure drag precisely in the first place. Even after careful measurements are made there is no way to know exactly how much of the drag is due to which part of the airplane, since they cannot be isolated from one another. The Mustang exceeded performance expectations from the outset, and it was only human nature for different contributors to the design to suppose that their part was responsible.

Different people commonly give different accounts of events that take place within large organizations. Atwood’s and Horkey’s versions of the Mustang’s origins are not strictly incompatible, but the dueling articles and letters generated by their disagreements, decades after the facts in question, hint at more than mere differences of viewpoint. It appears likely that Horkey, Irv Ashkenas and Edgar Schmued liked one another and liked Kindelberger, but were perhaps not so fond of Ray Rice and even less fond of Atwood. Atwood himself spoke of Schmued, who is now generally called the “designer” of the Mustang, with undisguised condescension.

On the other hand, Horkey’s “Real Story” article named a great many people who made significant contributions to the P-51—many of them former students, as Horkey and Ashkenas were, of the great aerodynamicist Theodore von Kármán at Caltech—but conspicuously omitted Atwood, who, Ashkenas recalled, was “off selling things” with Kindelberger while the P-51 prototype was being built. In fact, speaking of the aerodynamically hideous 75-gallon underwing tanks that were later added “by Wright Field and someone at NAA” to extend the Mustang’s range, Horkey reported that he, Schmued and Rice “fought their use but were overruled by someone higher at NAA.” That antagonistic and anonymous “someone” can only have been Atwood.

After the death of Dutch Kindelberger in 1962, Lee Atwood became head of North American. In contrast to the amiable Kindelberger, Atwood was perceived as stiff and distant, and by some even less kindly. His position, to be sure, was difficult; he was enough of an engineer himself, and an intelligent one, to be torn between his technical instincts and his murkier obligations as a salesman and the head of a major aerospace and defense contractor. He presided over North American at the time when its reputation was sullied by the dreadful Apollo 1 fire that incinerated three astronauts during a routine ground test in January 1967. A year later, Rockwell acquired NAA, and Atwood became CEO of the merged firm. He relinquished that post in 1970, becoming chairman of the board until his retirement in 1978.

Atwood died in 1999 at the age of 94. Horkey, Ashkenas, Schmued and all the long list of contributors to the Mustang—they are gone now as well. The airplane, on the other hand, seems immortal. Practically given away at the end of the war, surviving P-51s now trade for millions of dollars among museums, wealthy sporting pilots and air racers. With souped-up engines and stripped-down airframes, they achieve low-altitude speeds exceeding 500 mph at the annual Reno Air Races.

The mystique of the Mustang is due to many things: its performance, its classically elegant shape, its starring role in the war. For Lee Atwood, there was something else about it that appealed to his instincts as an engineer-turned-businessman. Though Atwood led North American through the jet age and into the space age, he wrote nostalgically at the end of his life about what sounds more like a golden age: “I doubt I shall ever see again such a degree of product improvement, employee participation, relative product value, economic production, and generally superior results as I experienced in Dutch Kindelberger’s airplane production complex during the period 1939 to 1945.”

The Mustang came into being before the individual engineer or craftsman, as a recognizable, nameable human being, was supplanted by the anonymous myrmidons of the giant defense contractors. It is understandable, in the context of Atwood’s nostalgia for that time, that he and others fought 50 years later to be remembered among the Mustang’s creators.

Peter Garrison, a lifelong aviation writer and amateur designer and builder, loves the P-51 and the Jaguar XK120 roadster equally, but has never been able to possess either. Further reading: Mustang Designer: Edgar Schmued and the Development of the P-51, by Ray Wagner; The Real Stuff: The Story Behind the P-51 Mustang, by Edward J. Horkey; and Building the P-51 Mustang, by Michael O’Leary.

This feature originally appeared in the September 2015 issue of Aviation History. Subscribe here!