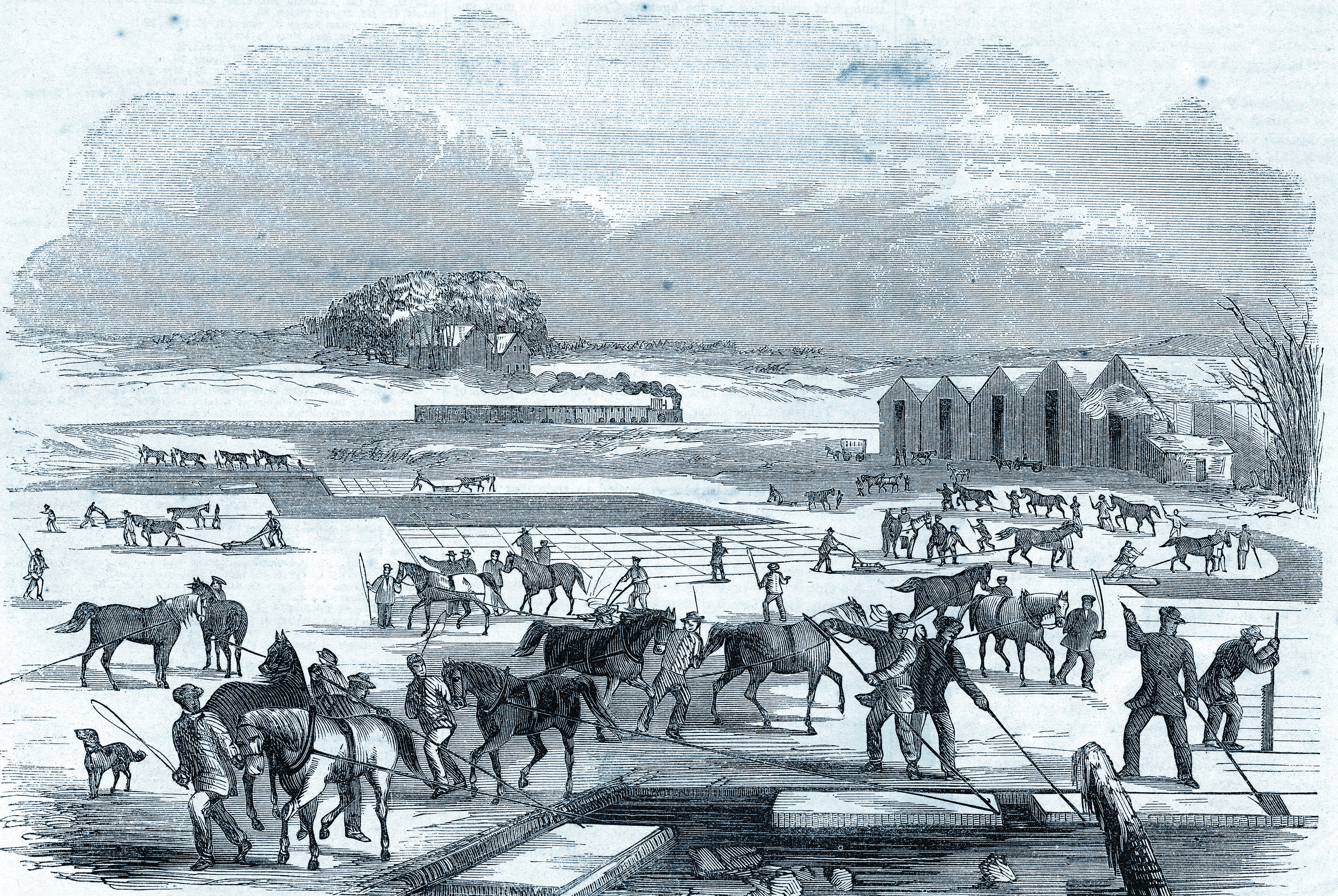

Until the 19th century, ice fit for human consumption was scarce, hacked and sawn by hand, and available only locally in limited, highly prized quantities. Ancient cultures learned to harvest natural ice and, taking advantage of the weather, even to cause ice to form, storing the result in insulated pits and structures. Gentry in England and other European countries built thickly insulated icehouses set in the ground with channels to drain meltwater. Colonists in New England, seeing Indians use caves, springs, and deep wells to retard food spoilage, did the same until they, too, erected icehouses in which to store ice cut from ubiquitous freshwater ponds left across the region by glaciers. Ice harvesting had to wait until deep winter froze fresh water to a depth of 14 to 16 inches, strong enough that crews with tools, horse teams, and sleds could work safely. In January and February, laborers or enslaved workers chopped away, producing uneven slabs. That awkwardness eased with the development of special ice saws, but freehand cutting still left blocks irregularly sized.

New World icehouses adhered to the English model: positioned to catch cooling winds, with plank floors set above a foot of drainage-ready sand to facilitate air circulation. Between icehouses’ inner and outer walls, roofs and ceilings, builders packed insulation: tanners bark—oak or hickory bark used to finish leather—charcoal, sawdust, hay, straw, or wood shavings. Workers arranged blocks in tight stacks, insulating them between layers with sawdust or salt hay. “The best ice houses often had a shrinkage of ice from between 10 to 30 percent between cutting and delivery,” a harvester claimed. George Washington, Thomas Jefferson, James Monroe, and other members of the American elite had personal icehouses to conserve that ephemeral luxury.

In 1802, needing to cool goods bound for market, Maryland farmer Thomas Moore invented what he called an “icebox”—a tin container set in a wooden tub, with crushed ice packed tightly into the spaces between. Moore’s 1803 patent for his invention was signed by President Thomas Jefferson, who so admired the device that he bought one. As the century progressed, variations on Moore’s creation wove their way into private and commercial life.

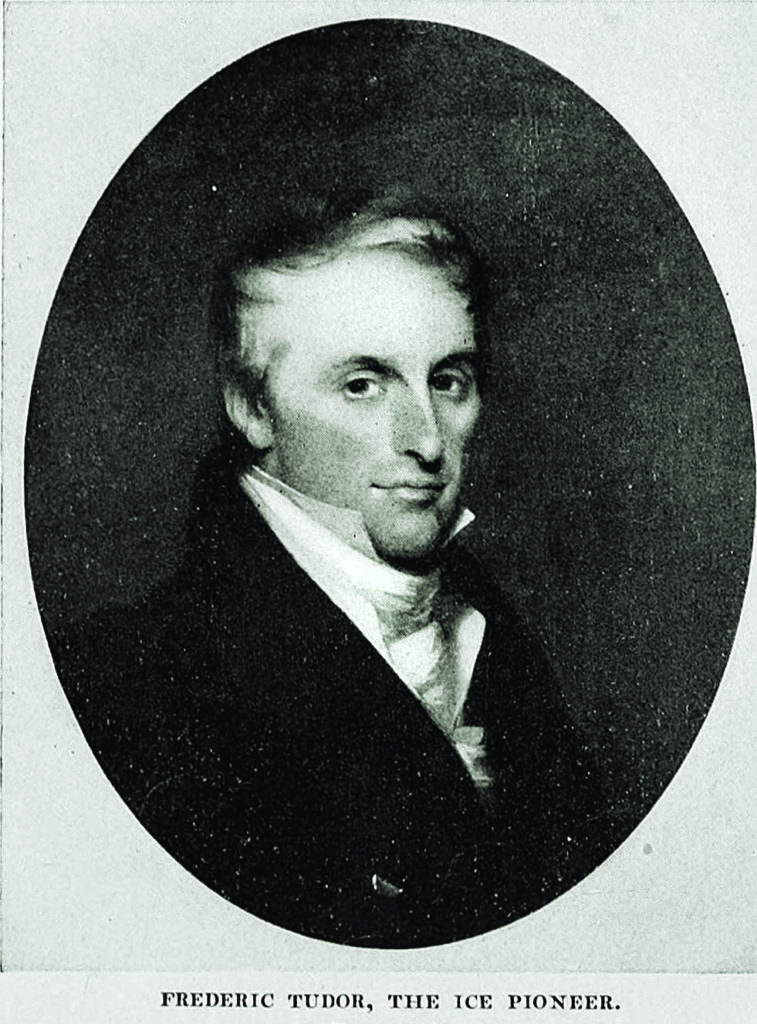

An entrepreneurial New Englander made ice a worldwide commodity. Frederic Tudor, third son of a lawyer with a practice in Boston, was born in that city on September 4, 1783. On a pond outside Saugus, Massachusetts, 10 miles north, the Tudors had an estate, Rockwood, that included an icehouse. Frederic could have attended Harvard College but instead went into accounting. In the late 1700s, his grandfather left him $40,000. Partnering with older brother William, Frederic put his inheritance toward starting a business harvesting and selling ice from the Rockwood pond. In his first entry in what he titled his “Ice House Diary,” Frederic Tudor wrote, “Plan etc for transporting Ice to Tropical Climates. Boston Augst 1st 1805 William and myself have this day determined to get together what property we have and embark in the undertaking of carrying ice to the West Indies the ensuing winter.”

Tudor’s grand idea was to export ice to climes where no ice existed. When he broached this idea to ship owners, they rebuffed him, reasoning that a cargo of ice could make a vessel unstable at sea and likely would melt before delivery, ruining other goods. During the 1806 ice cutting season, Tudor, 22, bought a brig, Favorite, for $4,750. He hired crews to harvest and store ice from the family pond, hauling 130 tons of blocks to the Boston docks in wagons. Its cargo insulated with hay and sawdust, Favorite departed Boston on February 10, 1806, for St. Pierre, Martinique. “No joke. A vessel with a cargo of 80 tons [sic] of Ice has cleared out from this port for Martinique,” the Boston Gazette reported. “We hope this will not prove a slippery speculation.” Tropical St. Pierre had no icehouse, so Tudor sold such ice as survived the three-week voyage straight from the ship’s hold, losing $4,500 but establishing his concept’s validity. He continued to transport ice to the Caribbean, opening markets around the region and obtaining an exclusive on selling ice on Martinique.

Tudor turned his first profit in 1810, when despite what he called “villainous conduct” by his local agent he cleared $1,000 on tropical sales of $7,400. The 1810s proved volatile. Embargos on American shipping interrupted work, then led to the War of 1812 and cessation of shipping. Debts totaling $38,772 landed Tudor in debtor’s prison. He secured a $2,100 loan to finance an ice harvest and start work on a 150-ton icehouse in Havana, Cuba. He leased a transport, George Washington. On November 1, 1815, dogged by creditors and steps ahead of the sheriff, Tudor sailed from Boston for Havana. His icehouse was unfinished, but he stocked it anyway and by March was nurturing a Cuban ice market. “Drink Spaniards and be cool that I, who have suffered so much in the cause, may be able to go home and keep myself warm,” he wrote in his diary. Soon Tudor was shipping ice from Massachusetts to Cuba efficiently and profitably. Most commerce between the West Indies and Boston was northbound. Ice, handy as ballast, made a convenient southward cargo, so in addition to operating his own fleet Tudor was able to ship ice on vessels that otherwise would have left Boston laden with other ballast.

Thinking to capitalize on his own ships’ return voyages, Tudor decided to try importing produce from Cuba. In August 1816, borrowing $3,000 at 30 percent interest, he sent leased schooner Parago to New York loaded with crates of limes, oranges, plantains, bananas, coconuts, and pears packed in ice. On the month-long voyage, most of the fruit rotted, setting him back $2,000. Again facing time in debtor’s prison, Tudor started building an icehouse in Charleston, South Carolina, where he advertised that customers paying $10 a month in advance would be able to reserve regular supplies of ice. A cargo delivered by his ship Milo sold well, and Tudor expanded that service into Savannah, Georgia.

In New Orleans, Louisiana, Frederic and William Tudor went in on an icehouse with brother-in-law Robert Gardiner, assigning their brother Harry to scout a site and manage the business. Frederic sent carpenters and lumber. Harry at first stocked the facility with ice purchased from a competitor in Marblehead, Massachusetts. The partners were hoping to gross $10 a day; soon the New Orleans icehouse was taking in $40 a day. As the 1820s neared, however, Tudor’s monopoly in Martinique ran out. Falling profits and loss of confidence in his agent there led him to close that venture. His icehouse manager in Cuba was killed in a robbery, and then that man’s successor died. Tudor sank into a depression.

Gardiner, heir to a fortune, advanced Tudor a saving stream of cash. “I can not say what would have become of me but for his stepping in to relieve me,” Frederic Tudor told his mother in a letter. By winter 1822, Tudor had emerged from his funk. Leaving the business in Gardiner’s hands, he sailed to Havana and stayed a year. Up in Boston, Gardiner’s stewardship revived the company. In New Orleans, Harry was continuing to outdo expectations.

Among locales in Tudor’s New England pond network was 155-acre Fresh Pond in Cambridge, Massachusetts. Nathaniel Wyeth, whose father operated the Fresh Pond Hotel, was harvesting ice that he sold to Tudor. An inventive fellow, Wyeth designed tools and systems for removing and handling the cold commodity. In 1824, Tudor hired Nathaniel Wyeth to supervise harvesting for Tudor Ice.

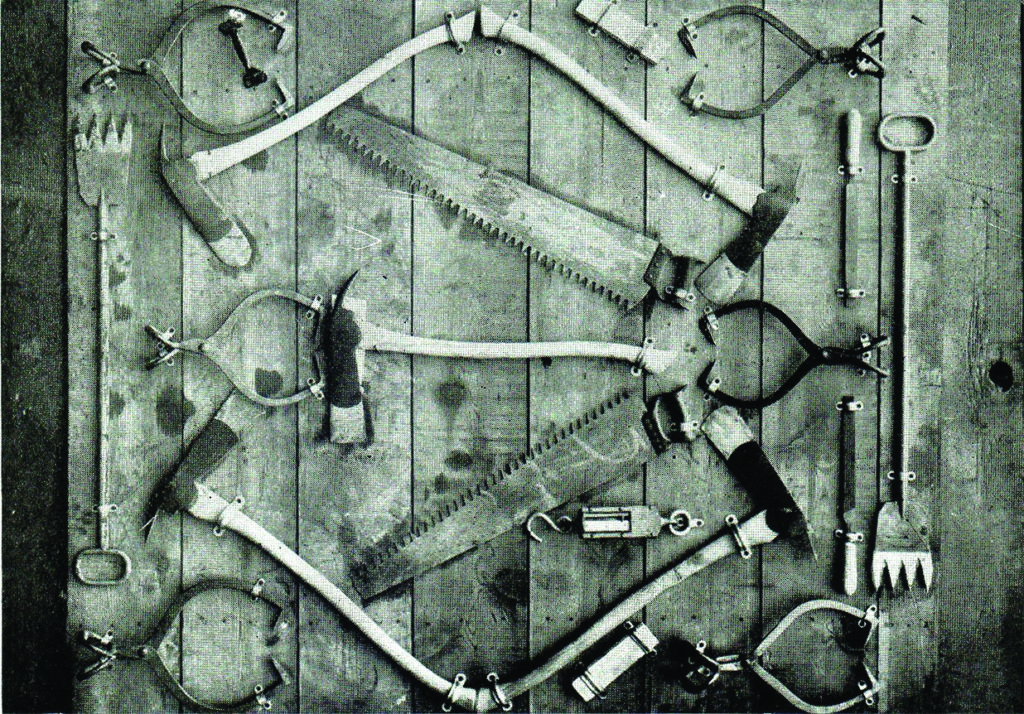

Convinced standardization would enhance efficiency and market appeal, Wyeth devised weighted ice-cutting sleds with serrated runners. First making a series of parallel straight cuts deepened with multiple passes, the driver repositioned his blades to the perpendicular, outlining blocks sized by the distance between runners.

Workers with long-handled chisels broke the blocks loose. The smallest, sold locally, were 22 inches square. Blocks to be shipped farther were cut larger to account for melting in storage and transport. Wyeth designed oversized tongs for muscling blocks and a means of top-loading an icehouse. Using two counterweighted horse-drawn platforms, workers hoisted blocks to a rooftop hatch. While that load was sliding inside on a chute, a second crew was below, stacking the other platform with blocks to be hoisted next pass. Though intensely manual, Wyeth’s innovative systems and tools brought natural ice closer to mass production. He and others also developed steam-powered conveyors to move blocks from pond to icehouse.

In 1826, Tudor Ice Company owned several vessels, including Iceland, Iceberg, and Ice King. From Tudor Wharves in Boston’s Charlestown harbor, the company was shipping 4,000 tons annually, a tally that reached 12,000 tons in 1836 and 65,000 tons in 1846. In 1833, Tudor shipped 180 tons of ice 16,000 miles from Boston to Calcutta, India. The transport Tuscany arrived with about two-thirds of its cargo intact, stirring great excitement, especially among resident Britons. “The first transport of Ice, from the shores of the United States to the banks of the Ganges, is an event of no mean importance; and the names of those who planned and have successfully carried through the adventure at their own cost, deserve to be handed down to posterity with the names of other benefactors of mankind,” wrote the Calcutta Courier. Within three days, Calcuttans were planning to build an icehouse—thus Henry David Thoreau’s comment in Walden that “The pure Walden water is mingled with the sacred water of the Ganges.”

Tudor’s success inspired competition. In 1842, Jacob Hittinger of Gage, Hittinger & Co., also harvesting at Fresh Pond, sent ice to London, where his representatives taught barmen to use it in drinks, American style. Losing $1,200, Hittinger quit the English market. Up stepped Charles Lander and Henry Ropes. They had been harvesting ice at Wenham Lake near Salem, Massachusetts, and hyperbolically touting their product, Wenham Ice, as longer-lasting thanks to being free of salts and bubbles. Queen Victoria awarded Wenham Ice a royal warrant, briefly endearing the brand to Britons.

In the 1840s, with railroads stitching the United States, Tudor Ice took to the rails. Trains extended the market for ice, and access to ice extended markets for dairy products, meat, seafood, and other perishables. With home iceboxes proliferating, the iceman with his wagon, tongs, and icepick became familiar along American streets, trailed on summer days by children trying to scrounge ice chips. The promotion-minded Tudor distributed handbills explaining how to use ice to preserve food, enliven the taste of carbonated water, and make ice cream and other frozen treats. Tudor’s salesmen went saloon to saloon giving away samples of ice and teaching cocktail-making. Tudor worked similar advertising magic in markets abroad.

Journalists likened the natural ice trade to the California gold rush. According to Hunt’s Merchant’s Magazine, Boston was leading the ice export league, by the 1850s annually shipping 110,000 tons to southern American cities and nearly 50,000 tons to the East and West Indies and other foreign locales. Mid-Atlantic states could harvest locally when winters were cold enough, with ice from Boston as a fallback. In 1855, New York City used 120,000 tons from Rockland Lake, 30 miles upstate. Harvests around Cincinnati, Ohio, and Chicago, Illinois, could not meet demand from area beer and food processors, leading to imports from the larger Great Lakes region. The biggest market for frozen water from Boston was the Deep South, with 520 vessels shipping out of Boston harbor in 1855 and ice comprising the largest tonnage of cargos from that port. Hunt’s estimated investment in the American ice trade at $6 million to $7 million, crediting the industry with generating 8,000 to 10,000 jobs. Ice had become a pillar of the economies of Maine, meteorologically more reliable than Massachusetts; Wisconsin, home to many food and beer companies; and Pennsylvania, a distribution center for perishables that served the Middle Atlantic states. “Ice is an American institution—the use of it an American luxury—the abuse of it an American failing,” De Bow’s Review wrote. “In workshops, composing rooms, counting houses, workmen, printers, clerks have their daily supply of ice. . .. We use it seven or eight months of the year—all the year in the south . . ..”

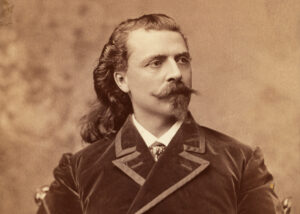

When Frederic Tudor died in Boston on February 6, 1864, age 80, he was a millionaire known as “The Ice King of the World.”

From 1857 until 1910, the annual American ice harvest enlarged. Winter 1879-80 produced a bumper yield. That season, the Census Bureau estimated, 113 million tons were cut, almost a million of which the producers shipped south. On a short stretch of Maine’s Kennebec River, the report noted, “[T]here is now more capital concentrated in the cutting and storage of ice than in any other locality of equal extent in the world.” Household consumption remained strong, but by the 1880s, the largest harvesters and users of natural ice had become brewers around Milwaukee, Wisconsin, and the fresh food industries based in Chicago, Illinois. Mechanically frozen ice was making inroads into the marketplace but seemed unlikely to replace natural ice, according to the Census Bureau.

The Census Bureau was wrong. The natural ice industry foundered amid a sea of troubles: industrial pollution of water sources, “ice famines” caused by climate shifts, labor turmoil, and monopolistic practices by American Ice, the largest natural ice dealer.

Within decades, the market was tilting toward mechanical refrigeration, which had improved dramatically since its introduction in the early 1800s. In 1801, engineer Oliver Evans, 46, had built the first high-pressure steam engine in the United States, opening a path toward artificial refrigeration. Evans went on to use steam engines to compress and expand gases. These advances led to vapor compression, which puts chemicals under pressure to cool air and is the basis for mechanical refrigeration. Building on Evans’s work, in 1835 Londoner Jacob Perkins patented a machine able to freeze small amounts of water. Perkins’s device inspired two American innovators. Alexander Twining built an ice plant in Cleveland, Ohio, able to make half a ton of ice a day. Floridian John Gorrie received the first patent for refrigeration issued by the United States. His system was not cost-effective, but by interweaving extant principles and designs James Harrison, a Scottish journalist living in Australia, in 1851 built the world’s first functional refrigerator, a two-story behemoth.

In 1873, German professor of thermodynamics Carl Linde developed a practicable refrigerator. The Linde Ice Machine Company soon was licensing manufacture of commercial and industrial equipment in the United States and Europe. In 1895, Cistercian monk and physics teacher Marcel Audiffren, of Grasse, France, received a patent in the United States for a home refrigerator. Within 40 years, with the development of small electric motors to drive compressors, home refrigerators were nearly everywhere, making clear, clean ice and leaving America’s natural ice industry in a puddle.

This story was originally published in the August 2021 issue of American History. To subscribe, click here.