The engine that today powers most commercial airliners and military aircraft traces its origins to a 1930 patent filed by a young RAF officer

Captain Monty Burton shut down the engines of British Airways Concorde G-BOAD at Dulles International Airport, outside Washington, D.C., and addressed the passengers: “We have covered the 3,900 miles from London to Washington in 3 hours 37 minutes, an average speed of well over 1,000 miles per hour and a maximum of 1,340. Today we had the great honor of carrying Sir Frank Whittle, who made all this possible.”

Whittle can justifiably be called the “father of the jet.” He was the first to build and run a turbojet aero engine. His 1930 patent application set down the fundamental design for a true turbojet light enough and with sufficient thrust to power an aircraft, and he pioneered features found in engines built 80 years later.

From a working-class family, he entered the Royal Air Force in 1923 the hard way, as an apprentice in a program that trained mechanics to service and repair airplanes. Except for a tiny few it promised a Spartan life under rigid discipline. But by virtue of his outstanding ability and hard work, in 1926 Whittle was one of only five apprentices, out of more than 600 in his class, selected to train as an officer at the RAF College in Cranwell.

Cadet training emphasized aeronautical engineering, and Whittle’s 1928 term thesis, “Future Developments in Aircraft Design,” predicted a rapid increase in speed, but noted that to achieve this aircraft would need to travel at high altitude to take advantage of reduced air resistance. However, piston en gines and propellers lose efficiency with increasing height, and there would inevi tably be a limit to both speed and altitude without a totally new kind of propulsive power.

Only one-fifth of the fuel energy in a piston engine propels the aircraft, the rest going to cooling and mechanical losses. In contrast, wrote Whittle, “the turbine is the most efficient prime mover known, so it is possible that it will be developed for aircraft….” It would convert most of the heat energy into propulsive force in the same way as a rocket, by the kinetic energy of hot gases escaping at high speed from the tailpipe.

The engine would essentially be a duct containing a single moving part: a shaft with a compressor at one end driven by a turbine at the other, itself powered by the energy from fuel burned in a combustion chamber between them. With none of the piston engine’s reciprocating parts, rotational speed and power output could be increased exponentially, and so long as there was even rarified air for the engine to breathe, altitude and speed would increase in quantum leaps. The faster and higher the aircraft went, the better a jet engine would work. “At the time I was working on this thesis the maximum speed of RAF fighters was less than 150 mph and the service ceiling about 20,000 feet,” Whittle said. “I was thinking in terms of a speed of 500 mph in the stratosphere.” And that would just be the beginning.

His thesis was the product of five grueling years in the workshops and study halls as an apprentice and flight cadet, while simultaneously training as a pilot. His tutor at Cranwell, O.S. Sinatt, said, “I couldn’t quite follow everything you have written, Whittle, but I can’t find anything wrong with it,” and awarded him the maximum grade.

Whittle graduated in 1928, just missing the Sword of Honor as top cadet but receiving the Memorial Prize for Aeronautical Sciences, having excelled in every area except contact sports, due to his diminutive size—he was barely 5 feet tall. The only negative note in his evaluation: “Over confidence. He gives aerobatics too much value. Inclined to perform to the gallery and flies too low.”

Wearing his new pilot’s wings, Whittle set out on his motorcycle to report to No. 111 (Fighter) Squadron at Hornchurch. “An ancient car driven by an ancient and deaf man shot out of a side road and I struck him amidships,” he related. “I shot over the car bonnet and landed in the road several yards beyond.” It was the first of several times he would cheat death. A few weeks later another crash ended his two-wheeled career, as his insurance company canceled his policy.

At Hornchurch Whittle demonstrated exceptional skill and performed feats that left his fellow pilots in awe. Soon he was selected to represent his squadron in formation flying and aerobatics. But a misjudged flick-roll at low altitude that came within inches of putting a wingtip into the Thames, and a later midair collision that wrote off his aircraft, sobered him somewhat. His superiors thought they might cool the young daredevil’s ardor by making him an instructor, so they posted him to the training station at RAF Wittering.

Intrigued by Whittle’s ideas, the commanding officer at Wittering arranged for him to report to A.A. Griffith at the Air Ministry research laboratory, who, unknown to Whittle, was working on the turbine as a better way to drive a propeller. It was a daunting experience for a newly commissioned officer of 22, but he felt reasonably confident of mak ing a convincing case for his concept of a potentially revolutionary power plant that could put Britain years ahead of its likely enemies.

He was to be bitterly disappointed. Griffith dismissed Whittle’s estimate of the propulsive power potential in the hot gas exiting the engine as foolishly optimistic and based on faulty calculations. Whittle later received an Air Ministry letter (probably written by Griffith) saying that they had no interest in pursuing his proposals, with the condescending “any suggestion submitted by people in the Service is always welcome,” and, “you may rest assured the criticisms of your scheme were made with the full knowledge of the results made by actual experiment.” This was untrue; no experiments had been conducted, or planned, on jet propulsion.

Despite having the door slammed in his face, Whittle was urged by RAF colleagues to apply for a patent, which he filed on January 16, 1930. Among its proposals: “The emission of gas may perhaps be directionally controlled for maneuvering purposes.” He also suggested spraying fuel into the gas flow before it exited the tail pipe to increase thrust, the concept behind today’s afterburner. Thus 82 years ago Frank Whittle had laid down the basis for modern fighters, bombers, helicopters and airliners; vectored-thrust aircraft such as the VTOL Harrier and F-35; and supersonic flight. As a serving officer he notified the Air Ministry, which expressed no interest in his patent and did not even put his invention on the secret list. So when the patent was granted, in October 1932, full specifications were published around the world.

Whittle was by then fully occupied with his RAF duties. To advance in rank and pursue a career, pilots were required to fly—in his case as a test pilot and at air displays—as well as perform the other duties of an officer, study for promotion examinations and be available at any time for overseas posting. While practicing for the 1930 airshow at Hendon, Whittle managed to wreck two airplanes, earning a rebuke from a furious flight commander: “Why don’t you take all my bloody aeroplanes, make a heap of them in the middle of the aerodrome and set fire to them—it’s quicker!”

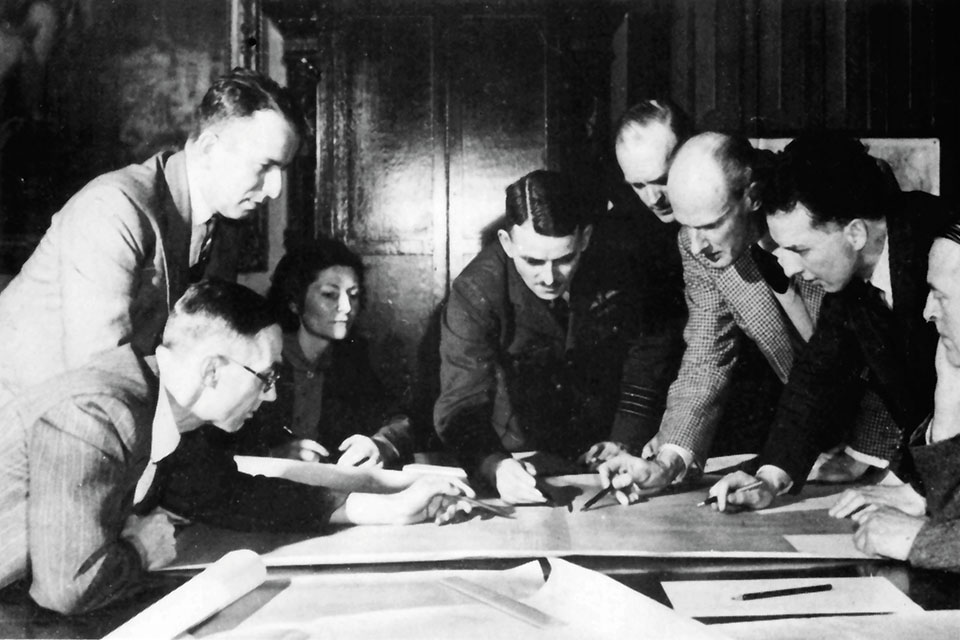

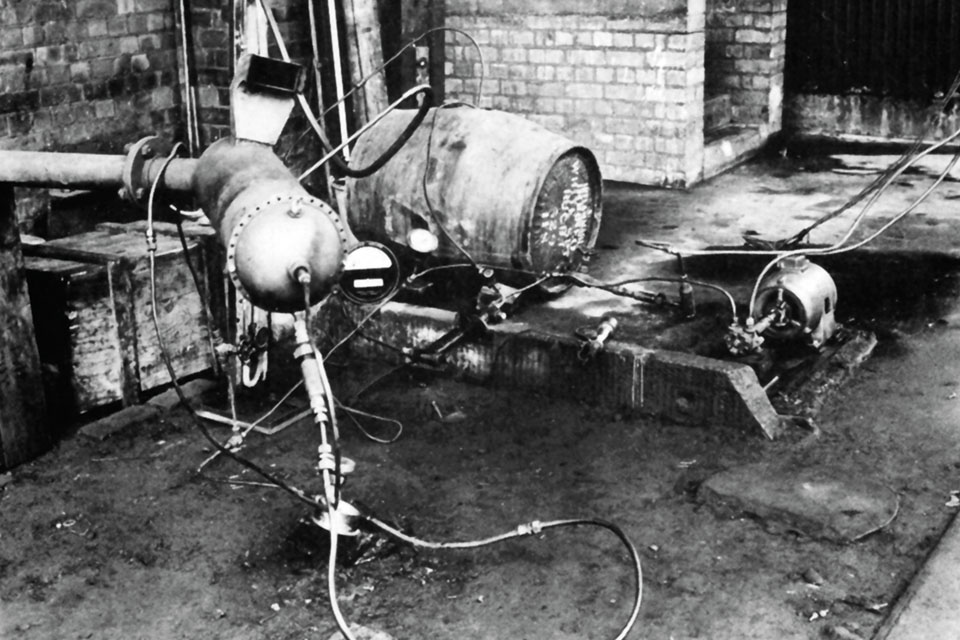

Whittle’s patent expired in 1935 because the Air Ministry refused to pay for its renewal, and he couldn’t afford to do so, but some ex-RAF friends obtained sufficient funding from investment bankers for the formation, in March 1936, of a tiny company called Power Jets. Whittle began work on a prototype engine, the WU (Whittle Unit), in an old, disused foundry building near Coventry. The RAF made a rare exception to the rule forbidding serving officers from involvement in commercial enterprises, provided it did not take him away from his regular duties for more than six hours per week, regarding it essentially as a spare-time hobby.

The same year, Hans von Ohain, a young physics and aerodynamics student at Germany’s University of Göttingen, applied for a patent for a “Process and Apparatus for Producing airstreams for Propelling Airplanes.” In contrast to Whittle’s humble origins, von Ohain’s family was of the Prussian military aristocracy. His design was not a true turbojet—a self-contained engine using the energy from its own power turbine to turn the intake air compressor. It used an electric motor to power the compressor, a technological dead end that was tried in several other countries, including Japan and Italy. When he attempted to run a prototype, he could not control the combustion process. Flame shot out in the reverse direction and destroyed the electric motor.

Richard Pohl, director of the university’s Physics Institute, discussed von Ohain’s idea with his friend Ernst Heinkel, whose company was designing aircraft for the reemergent Luftwaffe but had no experience with engine building. Heinkel was obsessed with fast aircraft, and the jet might afford him both an entry into the aero engine industry and put his firm well ahead of its competitors in performance. He arranged for von Ohain to present his ideas to the company’s engineers, who determined that, while his design would never work, the concept itself was interesting. On that basis, von Ohain was given Heinkel’s full backing.

The race was on to develop the first practical turbojet aero engine, though the odds were stacked. One contestant was operating on a shoestring in a decrepit foundry, without either government or industrial backing, in whatever time he could spare from his air force commitments. The other had the resources of a giant industrial concern, with its engineers and scientists, and could devote full time to the project. And while Whittle had no inkling of what was going on in Germany, Heinkel would soon be monitoring his progress.

Whittle’s original funding, plus another £100 from a lady who ran a corner shop near his parents, was almost gone by this time. The Air Ministry’s response to his request for a research grant came from D.R. Pye, deputy director of scientific research: “It is hardly likely you will be successful where so many better-equipped people have failed”—a bureaucratic Catch-22: Because of your lack of equipment you won’t succeed, but we won’t give you money to buy any.

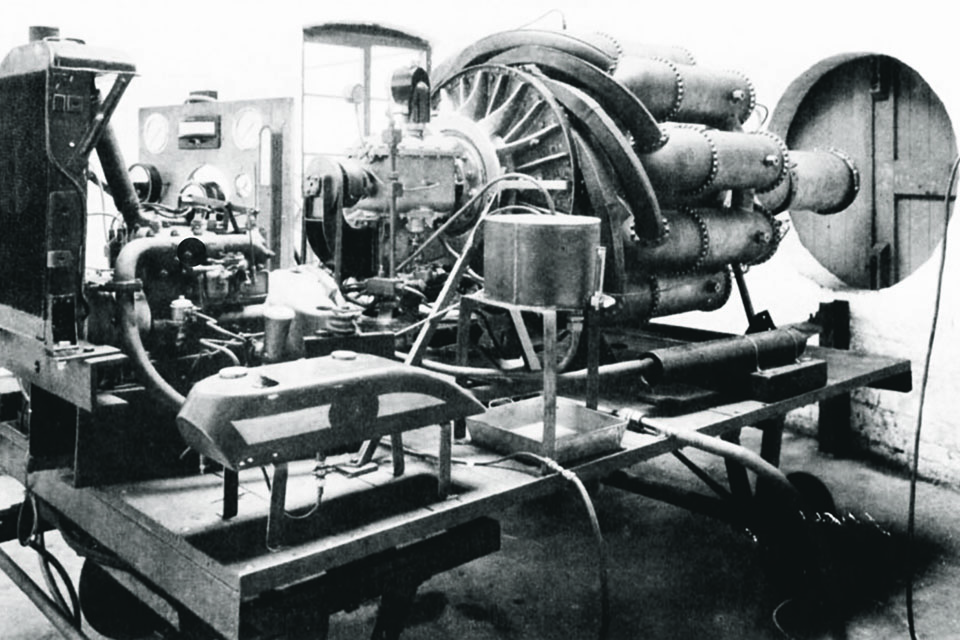

There was just sufficient cash for apprentices at British Thomson-Houston (BTH), a large engineering firm in Rugby, to assemble a prototype engine. It was revolutionary, unlike anything previously seen. Whittle calculated that each minute the 19-inch compressor would deliver 13,000 cubic feet of air to the combustion chamber while burning four gallons of fuel, with the power turbine supplying more than 3,000 hp to the compressor. Stanley Hooker, the genius largely responsible for doubling the power of the Rolls-Royce Merlin piston engine, wrote: “For the preceding 30 years the performance of piston engines in flight was only known to a very rough approximation based on inaccurate formulae, yet Whittle predicted what a jet engine would do before he had ever made one….40 years later, his formulae [were] used unchanged.”

On April 12, 1937, the engine was started. It was notable both historically and for what happened next. Whittle recorded: “I opened the control valve which admitted fuel….For a second or two the speed increased slowly. Then, with a rising shriek like an air-raid siren, the speed began to rise rapidly and large patches of red heat became visible on the combustion chamber casing. The engine was obviously out of control.” Sheets of flame shot out the tail pipe and escaped from joints in the casing, soon encasing the whole rig in flames. As the others took to their heels, “I remained rooted to the spot, not because I was particularly brave but because I seemed to be paralyzed with fright. I screwed down the control valve immediately, but this had no effect and speed continued to rise. Fortunately the acceleration stopped at about 8,000 rpm, and slowly the revs dropped again.”

The same thing happened on the second run. Fuel was pooling in the combustion chamber when the fuel pump was tested prior to start-up, and continued to power the turbine even with the fuel supply turned off. A simple drain cock solved the problem. The jet age had begun.

That same month Heinkel built a completely new design with many changes from von Ohain’s, called the HeS2. In September von Ohain had the satisfaction of seeing his first turbojet run, unaware that Whittle had beaten him by five months.

After the runaway engine experience, BTH forbade any more test runs inside their factory, so subsequent tests were conducted in the yard or back at Power Jets’ old foundry building. Luckily for the future of British jet engines, the Air Ministry placed Whittle on the Special Duty List, allowing him to work on the engine full time. And Sir Henry Tizard, chairman of the Aeronautical Research Committee, arranged for a government contract worth £10,000, the original merchant bankers contributed another £3,000 and even BTH, seeing possible future manufacturing potential, added £2,500.

By April 1938, the modified engine was ready. Ironically, the previously uninterested government now put the project under the Official Secrets Act. The September Munich crisis added urgency, but funding was again drying up and tests on new designs at Power Jets resulted in a series of breakdowns. The strain was affecting Whittle’s health. While the Reichsluftfahrtministerium (RLM) in Germany had more than 2,000 engineers working on 12 jet projects, he—with a running engine—was still finding it difficult to get proper backing.

Then, he noted, “on the 26th June 1939 we ran up to 16,000 [rpm]. We did several runs up to this speed.” After observing a 20-minute run at full power, the same D.R. Pye who had been so dismissive three years earlier asked Whittle if he was willing to proceed, at the risk of damaging his RAF career. The Air Ministry would buy the experimental engine but leave it with Power Jets for further development, and arrange for an airplane to be built for it.

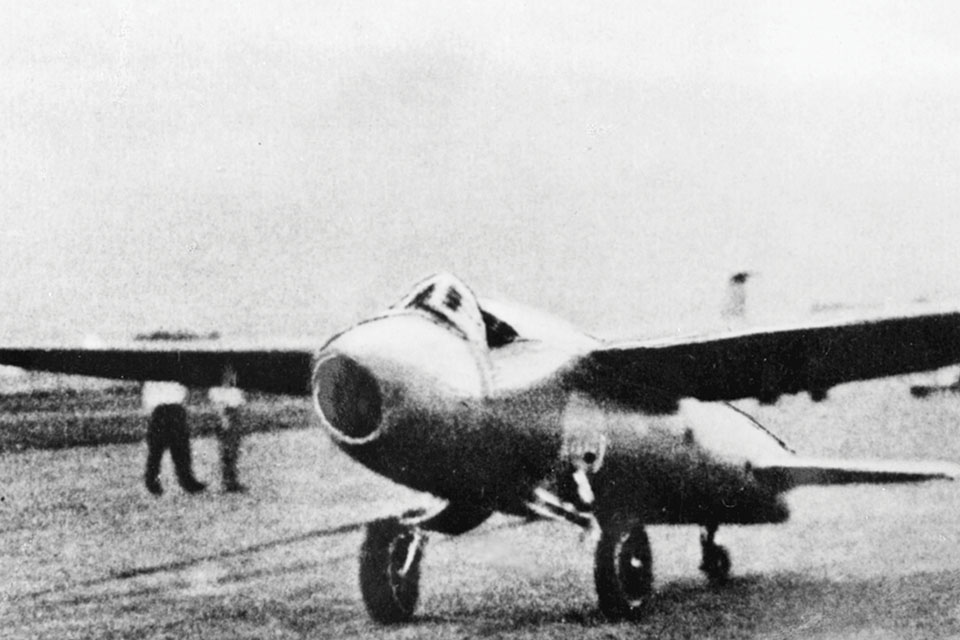

On August 27, as Adolf Hitler’s troops moved up to the Polish border, the HeS3B, in the Heinkel He-178 V1, made the world’s first jet flight, and Whittle’s first production engine, the W1, ran successfully at 94 percent of full design speed. One week later the panzers crashed into Poland, igniting a second world conflagration. The race now developed into which country could produce the first combat jet aircraft.

The He-178 V1’s historic flight proved little beyond the feasibility of jet aircraft. Its engine design was abandoned and, luckily for Britain, Heinkel encountered his own share of official indifference. Luftwaffe and RLM officials who witnessed the plane flying told him: “Your turbojet is not needed. We will win the war on piston engines.” Helmut Schelp, the RLM’s director of jet development, gave full details of the latest research to BMW and Junkers, who began developing their own engines. By now von Ohain was becoming increasingly sidelined. Heinkel’s turbojets retained little of his original concept, and none of his designs went into production.

Frank Whittle was still testing his W1 in the same derelict foundry, achieving 1,240 pounds of thrust, although several failures were caused by fine foundry sand falling from the ceiling when the engine was run. Nevertheless, design progressed to the W2, with a projected 30-percent power increase.

Air Chief Marshal Sir Hugh Dowding, commander in chief of Fighter Command, was a keen advocate of technical development (he was mainly responsible for the chain of radar stations that would be crucial in the Battle of Britain). He was interested in this new invention by one of his junior officers, and in 1940 paid Whittle a visit. It was a near disaster.

“I was sure something was bound to go wrong,” Whittle wrote. “It did….While the experimental engine was running, I pointed to the nozzle, meaning to imply ‘that’s the business end of the engine.’ Misunderstanding my gesture, he walked rapidly in the direction indicated. Suddenly a mighty invisible force sent him staggering across the concrete.” The unflappable Dowding, recovering his hat, jokingly asked the horrified Whittle “if I wasn’t going to show him something.”

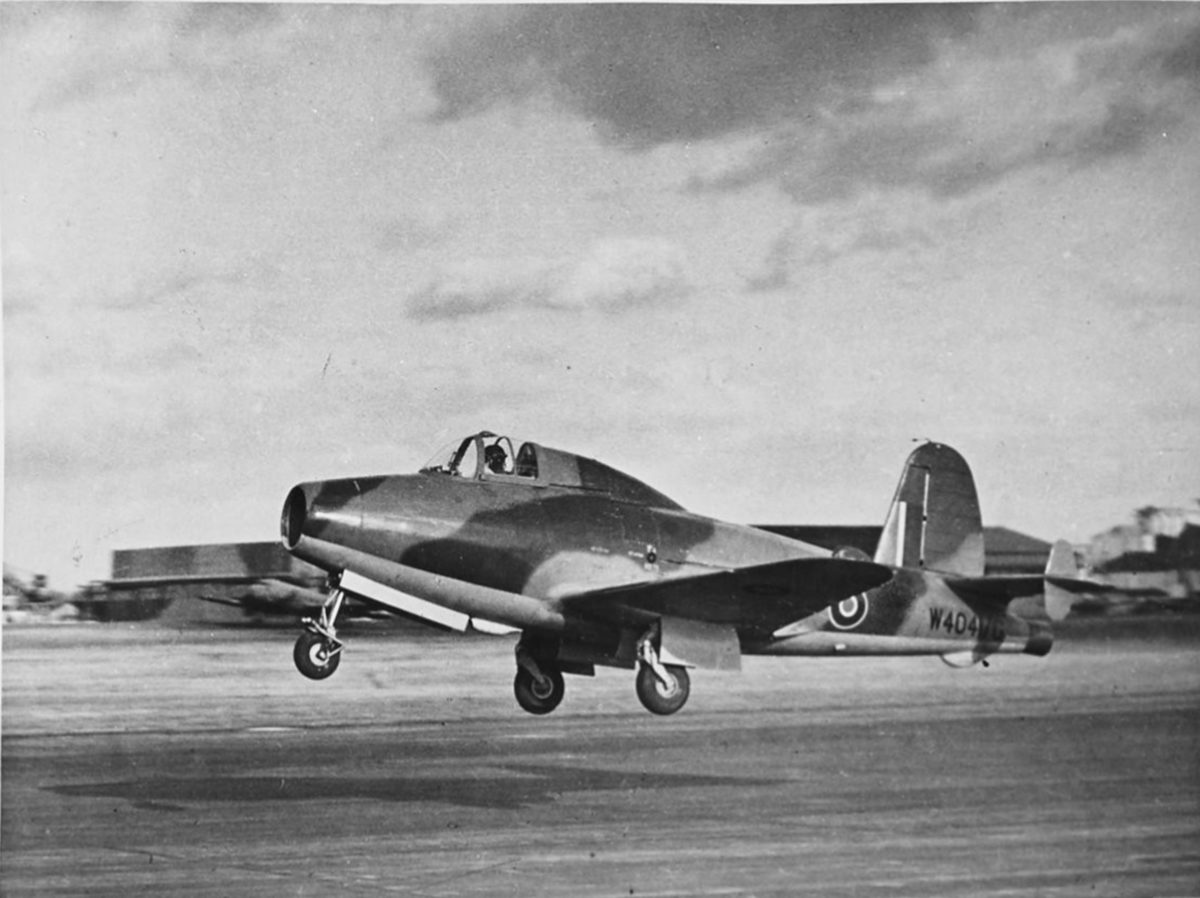

On a mission to Britain in March 1941, General Henry “Hap” Arnold, U.S. Army Air Corps chief of staff, was amazed to learn that Whittle’s engine would soon fly. On May 15, Gerry Sayer took off in the little W1-powered Gloster E.28/39 Pioneer—history’s second jet aircraft. With the W2 it would later hit 488 mph. Arnold arranged for a Whittle W.1X, engineering drawings and some Power Jets engineers to be flown to the U.S. to help jump-start America’s jet program.

The Air Ministry meanwhile told Whittle that the Rover car company would manufacture the W1, with Power Jets restricted to research. Incredibly, despite Britain being at war, almost two vital years were then lost because of bureaucratic inertia and professional jealousy. By late 1942, Rover had made fundamental changes to Whittle’s pioneering design, his suggestions were largely ignored and virtually no progress had been made on the W2.

Ernest Hives, head of Rolls-Royce’s aero engine division, saved Britain’s jet program from disaster. He took Rover’s chief engineer to dinner and did some horse-trading: “Give us this jet job and we’ll give you our tank-engine factory in Nottingham.” Rover had done only 24 hours of testing; the next month Rolls logged nearly 400, armed with a letter in red ink from Sir Stafford Cripps, minister of aircraft production: “Nothing, repeat nothing, is to stand in the way of the jet engine.”

De Havilland also began to manu facture an engine similar to Whittle’s original 1930 patent, achieving a record 3,100 pounds of thrust. (A modified version, called the Ghost, would power the de Havilland Vampire, Britain’s second jet fighter, and the later Comet airliner.)

In 1936 Whittle had also patented the turbo fan engine (used on almost every airliner today), promising quieter operation and greater fuel economy. In 1943 Power Jets was close to completing a prototype, the LR.1, when the company was nationalized and told that it must never build another engine.

In Germany, RLM Director Schelp refused further funding for Heinkel’s jet engine work, effectively ending that pioneer company’s involvement. When the Luftwaffe’s chief test pilot was killed flying the Messerschmitt Me-262 V3, official interest in jet aircraft again waned. The production version Junkers Jumo 004B-1 engine would not go into full-scale production, together with the Me-262, until mid-1944.

The Rolls-Royce Welland I, a development of the Whittle W2B, powered the new Gloster Meteor fighter. The first Meteors were delivered to No. 616 Squadron on July 12, 1944, and two weeks later it became the first Allied jet to enter operational service, the Me-262 having already flown combat missions. One Meteor was sent to the U.S. for evaluation. The Meteor and Me-262 were destined never to meet in combat. History’s first jet-versus-jet encounters involved Meteors shooting down the world’s first cruise missiles, the pulse-jet-powered V-1 flying bombs.

In October 1945, Frank Whittle piloted a jet for the first time, a Meteor F.4 powered by a later version of the Welland, the Derwent V. A few days later it set a world record at 606 mph. A modified version of the Derwent originally developed by General Electric, the Allison J33, would power the United States’ first production jet fighter, the Lockheed P-80 Shooting Star.

In the end, the jet engine played no significant role in the war. By the time jets were in operational use it was “too little, too late” for both nations. Hans von Ohain later said: “If the British experts had had the vision to back Whittle, World War II would probably never have happened. Hitler would have doubted the Luftwaffe’s ability to win.”

Toward the war’s end, a series of increasingly powerful engines emerged from Rolls-Royce, which went on to become arguably the preeminent manufacturer of turbojets. By 1944 the Rolls-Royce Nene was producing 5,000 pounds of thrust. Britain’s postwar socialist government sold 25 Nenes and 35 Derwents to the Soviets, who reverse-engineered them and made 39,000 without a license, passing the design to China, where they were still being produced in 1979. The Soviet version of the Nene, the Klimov VK-1, was used in the MiG-15 fighter in Korea, with the bizarre result that in 1950 jet aircraft of all the combatant nations were powered by developments of British designs.

Frank Whittle, who retired from the RAF as an air commodore, was knighted by the Queen and received many other honors. Emigrating to the U.S. in 1976, he accepted the position of NAVAIR research professor at the U.S. Naval Academy. Whittle died at his home in Columbia, Md., in August 1996.

Whittle’s 1928 thesis and 1930 patent had led to a true revolution in military and civilian air travel. Thirty years after fighters and bombers had been hard-pressed to exceed 200 mph, their successors were traveling at 10 times that speed, and long-distance travel times were halved. Whittle’s original WU produced about 800 pounds of thrust, while today the Rolls-Royce Trent, working on the same principle, achieves more than 100,000. WWII’s mightiest bomber, the B-29, was powered by piston engines totaling some 10,000 hp, while the Olympus engines on the Concorde that flew Whittle to Washington developed the equivalent of 144,000.

Nicholas O’Dell served with the RAF as a navigation and bombing radar equipment technician from 1958 to 1962, working on nuclear bombers powered by descendants of Whittle’s original engine. For further reading, he suggests: Whittle: The True Story, by John Golley; The Development of Jet and Turbine Engines, by Bill Gunston; and Hans von Ohain: Elegance in Flight, by Margaret Connor.

This feature originally appeared in the March 2012 issue of Aviation History. Subscribe here!