James “Crash” Ryan’s research laid the foundation for the modern flight data recorder, contributing greatly to aviation safety.

Aircraft flight data recorders were around even before the beginning of manned, powered flight. Early lighter-than-air data was described by word of mouth or recorded via sketchy handwritten notes on altitude and wind direction. The Wright brothers used a crude instrument that measured time, distance and engine rpms on their Wright Flyers. Small barographs with a rotating paper drum and ink stylus were installed on many airplanes of the 1920s, including Charles Lindbergh’s Spirit of St. Louis. But up to the post–World War II era, as recorders became more sophisticated and commonplace, they all shared a common flaw: None could survive a catastrophic crash, resulting in the loss of important data just when it could have been most useful.

It was not for lack of trying. During WWII, the U.S. Army Air Corps and Civil Aeronautics Board had teamed up to encourage the development of survivable flight data recorders. There were two main reasons for this. First, with the growing numbers of training aircraft and flights, there were many more crashes resulting in crew casualties and extensive damage to aircraft. Training methods and structural designs were constantly revised in an attempt to decrease losses, so flight data was increasingly seen as helpful. Second, both military and civilian maintenance officers were frantically looking for ways to avoid the necessity for extensive visual inspections following erratic flight maneuvers and hard landings. They hoped that a reliable flight data recorder might sometimes take the place of a crew of mechanics spending hours inspecting an airplane for potentially dangerous damage. Several companies that were already doing war work started looking into recorder designs, but since that research tended to take a back seat to other more pressing needs, very little progress was made until after war’s end.

General Mills had been involved in the development of precision equipment for the Air Corps, as well as other military branches, since early in the war. Some of that work continued into the following decade. The company’s mechanical division started searching for an experienced engineer who could join its program to develop a new flight data recorder, known as the “FDR” project.

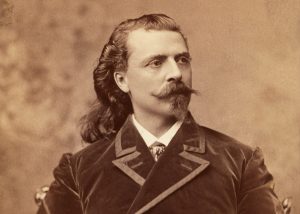

They selected Professor James J. Ryan, a graduate of the University of Iowa and University of Pittsburgh engineering schools. After working for Westinghouse during the early days of the Great Depression, Ryan had joined the University of Minnesota faculty in 1931. No stranger to military problem-solving, he had helped design precision recording altimeters, accelerometers and tensiometers during the war. With the onset of the jet age, Ryan became the lead researcher on a project for the U.S. Air Force aimed at determining at what altitude and speed it was safe for an ejecting pilot to deploy his parachute—or for an automatic release device to deploy the parachute if the pilot could not do so. His work on that project provided a good foundation for developing an accurate and survivable flight data recorder.

The General Mills team wasn’t alone in the attempt to create a new FDR. The French had tried variants of photographic recording equipment, but couldn’t solve the flammability issue related to film chemicals. General Electric had come up with what it called “selsyns,” small transmitters attached to every instrument, but which required a cumbersome loom of wiring and tubing that sent signals to the recording device. Other companies had tried to perfect a paper drum and ink system, but at high altitudes and low pressures the ink stylus clogged, froze or dried up. A few firms had also experimented with using white-lacquer-coated black paper, which was incised by a sharp stylus. The only thing all the developers seemed to agree on was that the safest place to locate the recording equipment was in the tail of the aircraft, since that was usually the last section to hit the ground in a crash. As one designer noted, “I never saw an airplane back into a mountain.”

Ryan’s approach was to make the device as simple as possible in terms of design, installation and service requirements. His team worked long hours, thoroughly testing every element and idea. He achieved his goals with the very first design. Ryan’s recording mechanism used a tiny electric motor to move a thin sheet of 2-inch-wide aluminum foil horizontally an average of 4 inches per hour. A small pointed stylus scratched an arc that created a timeline along the foil. The foil could survive temperatures of 1,000 degrees (2,000 degrees in subsequent designs) for 30 minutes and could withstand 20Gs.

To measure altitude, a precision aneroid bellows was connected with tubing to the aircraft’s pitot-static system. Airspeed was determined with a diaphragm that measured static and dynamic pressure at airspeeds up to 500 mph. A small weight on a cantilever balance beam measured acceleration (G forces from -3 to +12). Each of these three precision instruments was connected to its own separate pointed stylus that poked tiny holes in the foil as it moved along its track.

The 16-pound hatbox-sized “black box” was divided into two compartments, with the recording equipment positioned above and measuring instruments below. The only exterior parts were the wire supplying power to the electric motor, tubing attached to the aircraft’s pitot-static system and a line to the compass for directional headings. The container was sealed against humidity and moisture. In keeping with his promise of ease of serviceability, Ryan’s recorder, which he dubbed the Ryan VGA (for velocity, G-forces and altitude), could operate for 300 hours without servicing. Because of its minimal exterior attachments, the unit could be easily mounted in any aircraft’s tail section.

Initial tests of the new FDR were highly successful, but Ryan kept working on refinements. Subsequent designs incorporated a spherical casing in 1953, still with the two separate chambers, but better able to survive higher impact forces and temperatures. Modifications made the unit stronger, lighter and more convenient for installation and service. Of course all of this was long before microchips and electronic circuit boards, but for its time the Ryan VGA was state of the art.

General Mills eventually sold the design to Lockheed, which made slight adjustments but kept the same basic features. By 1957, the Civil Aeronautics Board (soon to become part of the FAA) had ruled that all aircraft over 12,500 pounds were required to have FDRs. Well into the 1970s, the units installed in all aircraft were based on the Ryan VGA.

Even though Ryan had completed his work on the FDR project, he was far from done with developing and testing transportation safety equipment. From his laboratory at the University of Minnesota, Ryan and his students launched an all-out war against automobile fatalities. During the 1950s and early 1960s, they crashed hundreds of cars in parking lots, on rural country roads, on laboratory “sleds”—even dropping them from 80-foot cranes to simulate a 40-mph crash. Because Ryan himself often strapped on a football helmet and sat behind the wheel during impact tests, he acquired the nickname “Crash.” He frequently appeared at county fairs and auto shows and on TV to campaign for automobile safety. He was a tireless crusader, using the media to urge Congress to enact legislation requiring manufacturers to make cars safer. “It’s such a silly thing,” he opined, “to allow people to become a statistic, by reason of death due to an automobile accident.”

Ryan and his students developed the first retractable seat belts, shock-absorbing hydraulic bumpers, swing-away steering columns and recessed dashboards, long before Detroit automakers made such safety features a priority. Only when the National Traffic and Motor Vehicle Safety Act and the Highway Safety Act were signed into law in 1966 did safety become a required part of automobile design.

By that time, due to ill health (and perhaps too many research crashes), Ryan had retired from the university. He died in 1973 at age 69, having given away many of his patent rights to help save lives. Before his death, he donated all of his research documents, drawings, photographs, films, teaching materials and FDR prototypes to the Buffalo Bill Museum in his hometown of LeClaire, Iowa. The museum now has a re-creation of Ryan’s University of Minnesota office on display, along with several prototype models of his VGA flight data recorder.

Today when we hear about accident investigators analyzing the data recovered from an aircraft’s black box, few remember the pioneering efforts that made it possible. James J. Ryan and other researchers and innovators like him got the ball rolling, to ensure that aviation safety continues to improve.

Scott M. Fisher, a former A&P instructor, writes from Davenport, Iowa. To learn more about Crash Ryan, he suggests contacting or visiting the Buffalo Bill Museum in Iowa (buffalobillmuseumleclaire.com).

Originally published in the January 2013 issue of Aviation History. To subscribe, click here.