The German engineer generated a steady stream of creative aircraft designs, but his actual production output was more like a trickle.

The German shipbuilding firm of Blohm & Voss, founded in 1877, had built such historic warships as the battle cruiser Scharnhorst and the battleship Bismarck at its shipyards near Hamburg. But its fortunes were at a low ebb in 1932 when, under the burden of a worldwide depression and the lingering impact of World War I, it was obliged to lay off workers. Casting about for a new source of revenue, the firm hit upon the unlikely idea of founding an aircraft-manufacturing subsidiary. Hamburger Flugzeugbau (HFB) consequently came into being in June 1933. Its first product, the Ha-135, was an attractive but entirely conventional biplane trainer that gave no indication of the imaginative designs to follow.

While retrained shipyard workers constructed the first Ha-135 prototype, HFB, having at its disposal a great deal of idle manufacturing capacity, secured a contract from the Reichsluftfahrtministerium (RLM)—the German air ministry—to supply aft fuselage and tail assemblies for the Junkers Ju-52 trimotor, a 17-passenger airliner with corrugated aluminum skin. The company would eventually build assemblies for more than 400 of these surprisingly durable airplanes, a few of which remained in service into the early 1950s and eight of which are still airworthy today.

Similar contracts followed. HFB built parts or entire airframes for 10 different types, including 1,577 tail assemblies for Messerschmitt Me-262 jets. It also built hundreds of trainer versions of several warplanes, such as the Me-109 and Ju-88. Contract work on other firms’ airplanes allowed HFB to rapidly expand its factory space and workforce, the former growing from 80,000 square feet early in 1934 to 260,000 two years later, while the latter swelled from 500 to nearly 2,000.

It was significant that the first outside project HFB undertook was a Junkers design. Junkers specialized in metal construction, and the future of aeronautical design clearly lay with aluminum. HFB accordingly set out to recruit engineering talent familiar with metal airframes. On the RLM’s recommendation, the firm approached German-born engineer Richard Vogt, who at the time was working in Japan. Vogt had been a protégé of German designer and manufacturer Claudius Dornier, one of whose designs had been produced under license by Kawasaki, like B&V originally a shipbuilding firm. In the late summer of 1933, Vogt returned to Germany to head HFB’s design department.

Vogt—talented, energetic, charismatic and above all creative—was a fortunate hire. It was as if a fledgling airplane firm in 1970 had plucked a young engineer out of obscurity and he turned out to be Burt Rutan. Nevertheless, Vogt’s first few projects at B&V were unsuccessful.

The first was a tiny single-seater with an all-up weight of 1,400 pounds. Dubbed the Ha-136 and first flown in the fall of 1934, it was nominally intended for pilots transitioning from primary trainers to fighters. Only two were built. The Ha-136 is noteworthy principally because it was the first Vogt airplane to make use of a tubular wing spar. The tubular spar became a hallmark of his subsequent designs, but few other designers have used it since (see sidebar, P. 45).

In the summer of 1934, the Ha-137, Vogt’s unsolicited entry in an RLM dive-bomber competition, lost out to the Junkers Ju-87 Stuka. Later that year, however, the RLM awarded HFB a contract to develop a marine reconnaissance aircraft powered by three 700-hp Jumo 205 opposed-piston 2-stroke diesels. Vogt’s design, a flying boat with a twin-boom empennage and loaded weight of about 30,000 pounds, placed the third engine on a pylon above the fuselage and used a gull wing with steeply angled inner panels to keep the outer engines as far as possible from the water.

Flight tests of two prototypes, designated Ha-138 V1 and V2, began in July 1936 and revealed that the combination of the gull wing and the central pylon had been an aerodynamic blunder. Vogt was forced to abandon the gull wing entirely, replacing the V-shaped center section with a straight one mounted atop the fuselage. The new version, extensively modified, did not fly for another year.

The airplane’s unusual appearance engendered some mockery. It was nicknamed the “Flying Clog” because of the shoe-like profile of its underslung fuselage, and the British magazine Aeroplane published a caricature with this caption:

Richard Vogt, that original man,

Turns out aeroplanes uglier than

’Most any other designer can.

Here is shown on Baltic Sea

A typical Vogt monstrosity—

The One-Three-Eight by B and V.

Various problems and changing requirements led to further delays, and it was not until four years after the original order that HFB began to deliver production airplanes, now designated BV-138s (the company’s two-letter designation changed in September 1937). Between 1940 and 1944, about 270 of the flying boats were built. Despite its ill-starred beginnings, the BV-138 proved to be an excellent reconnaissance aircraft and was the only HFB design manufactured in large numbers.

Concurrently with the 138, HFB launched several new projects. In 1935 Deutsche Lufthansa had requested a four-engine airplane capable of all-weather transatlantic passenger and postal service, with a payload of 1,100 pounds, a range of 3,000 miles and a cruising speed of 150 mph. Water takeoff was required only with sufficient fuel for a range of 600 miles; at maximum weight, the airplane would be launched from a shipboard catapult. Vogt consequently designed the Ha-139 as an aerodynamically clean, slender-bodied floatplane, with floats just large enough to sustain it at diminished weight. Its engines were the same Jumo diesels as were used in the 138.

The Ha-139 was a technical success. Only three were built, but they made more than 100 Atlantic crossings. HFB also built four prototypes of a landplane version, the Ha-142, replacing the floats with retractable landing gear. After brief service with Lufthansa, these were drafted into military service for long-range maritime patrol.

One peculiarity of the 139 was the rectangular planform of its 96-foot wing. Normally, one would expect such a large wing to be tapered, but Vogt’s fondness for the tubular spar, which doubled as a fuel tank, militated against taper, as it would have made fabricating the spars more difficult. About a year after launching the 139 program, however, HFB embarked on a similar but smaller floatplane, the Ha-140 torpedo bomber, equipped with two 900-hp BMW radials. Its outer wing panels were tapered, as were their tubular spars.

The tubular spar made possible an unusual experiment. The third prototype of the Ha-140 was equipped with outer wing panels that were socketed, like variable-pitch propeller blades, in 16-inch ball bearings housed within the engine nacelles. The bearings permitted the angle of the wings with respect to the fuselage to be changed in flight. The purpose of this novel arrangement was both to improve visibility by keeping the fuselage level during the landing approach, and to hold the empennage clear of rough water. The RLM was not impressed; only three Ha-140s were built.

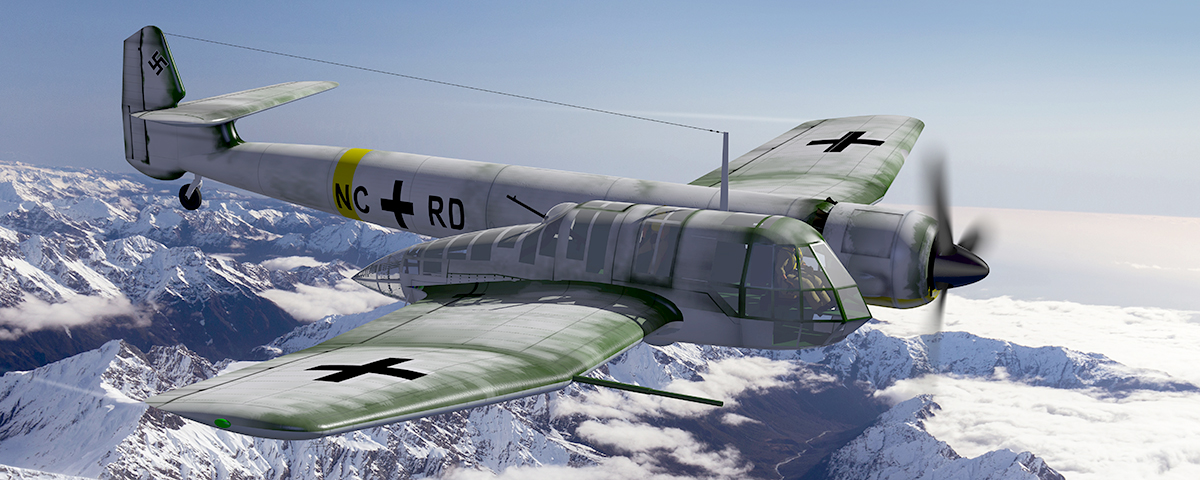

At the same time the Ha-140 was under development, Vogt was designing the airplane for which he is principally remembered and which best displays the originality of his thinking: the famously asymmetrical BV-141.

The BV-141’s single 1,560-hp BMW radial was mounted on the nose of a long boom from whose aft end sprouted a vertical fin and, in later versions, a horizontal stabilizer that extended almost entirely to the left of the fin in order to widen the field of fire for the tail gunner. The boom was set slightly to the left of the 50-foot wing’s centerline; offset to the right was a greenhouse pod housing a pilot, an observer and a defensive gunner. The airplane, which looked like a collection of random parts assembled by a whimsical child, gave rise to much humor and mockery, but also impressed pilots with its unexpectedly fine flying qualities. World War I ace Ernst Udet, then in charge of aircraft acquisition for the Luftwaffe, looped and rolled it on his first flight in April 1938.

The asymmetrical arrangement, although unusual to the point of shocking, was not aerodynamically unreasonable. An airplane is not symmetrical about a horizontal plane either—it uses trim to control unbalanced pitching moments. The same principle applies to asymmetry about a vertical plane: Unbalanced forces were minor and could be neutralized by small deflections of the rudder.

Unfortunately for Blohm & Voss, the Luftwaffe withdrew the observation-plane requirement that had motivated the 141’s daring configuration, and Vogt reconfigured the airplane as a light bomber. In all, 18 of them were built, including the prototypes, and deliveries ended in May 1943.

Early in the war it was assumed, at least in Germany, that the Third Reich would emerge victorious, and so airlines, among others, continued planning for postwar needs. Lufthansa required an airliner of the DC-3 class. Vogt responded with an 18- to 23-seat high-wing, twin-engine design that made use of the variable-incidence wing he had applied to one Ha-140 prototype. Construction of the airplane, the BV-144, was farmed out to the Breguet factory in occupied France, which built one prototype that flew a number of times. With the need for German airliners becoming increasingly remote, it was ultimately scrapped.

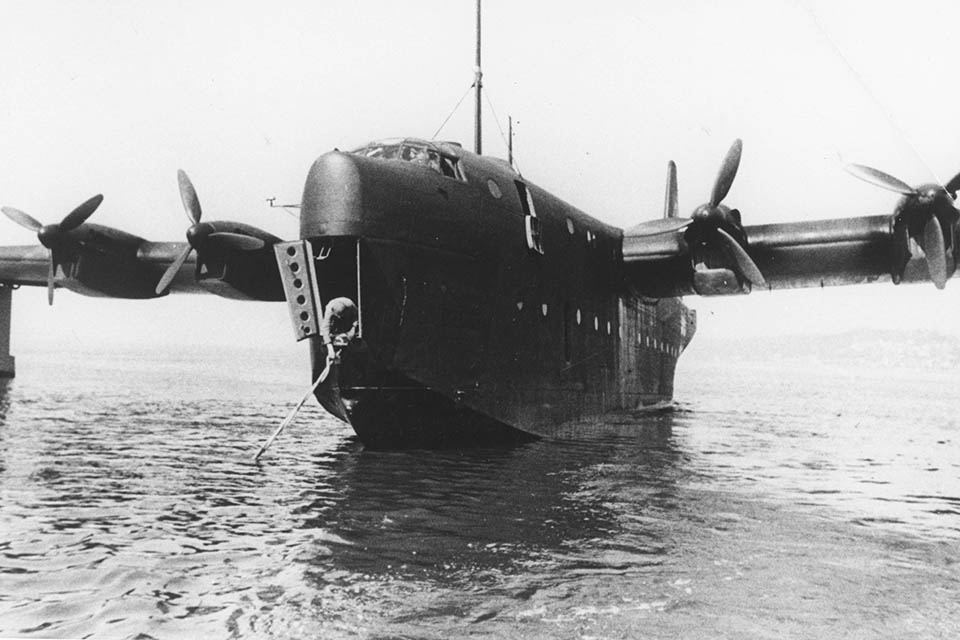

Another Lufthansa requirement, issued before hostilities began, was for a large transatlantic flying boat for cargo and passenger service to the United States and Brazil. In 1938 HFB began work on a conventionally configured flying boat of 150-foot span and a gross weight of 100,000 pounds. Vogt considered the then-standard complement of four engines, as used on the Sikorsky and Martin “Clippers” that Pan Am flew on its Pacific routes, inadequate for future development, so he elected to use six 1,000-hp BMW-Bramo radials. Designated the BV-222 Wiking (Viking), the first prototype rolled out in August 1940.

At that point, the war had been going on for almost a year. Instead of Lufthansa, the Luftwaffe took delivery of the production airplanes, beginning in May 1941. Thirteen were built, of which the last six, starting in May 1943, were equipped with Jumo opposed-piston diesels, which, because of their excellent fuel economy, were the logical choice for long-range oceanic patrols. Several, bristling with defensive armament that reduced their maximum speed from 240 to 188 mph, served over the Atlantic as target spotters for U-boats. By the end of the war, however, only three remained. One was taken to England and two to the United States; all were eventually scrapped.

At the beginning of 1941, HFB’s operations encompassed some 900,000 square feet of factory space and employed 4,400 workers. This was the period of peak production of the BV-222, and also of the launch of a new project, the BV-238, in response to an RLM request. A flying boat generally similar to the 222 in appearance, the 238 would at the time be the world’s largest airplane, with a wingspan of 197 feet and a takeoff weight of more than 200,000 pounds. It was powered by six 2,000-hp Jumo 223 diesels with methanol injection, supplemented, for heavy takeoffs, by four jettisonable rocket boosters producing 1,500 pounds’ thrust each. It had a cruising range of 4,000 miles at 200 mph. One of the schemes envisioned for the BV-238 was to attack New York with bombs taken aboard from a U-boat at a midocean rendezvous.

Shortly after the launch of the 238 project, Vogt sketched a landplane version, the BV-250. The scheme did not advance far. Neither did that of a still larger craft, the P (for Project) 200, which Vogt sketched in 1941 with the expectation that it could be built for Lufthansa after the war. It featured luxurious steamship-like accommodations for 120 passengers on three decks, with a “dancing bar and view room” surrounded by panoramic windows (the airplane was unpressurized) on the top level. With a wingspan of 280 feet, a takeoff weight of 460,000 pounds and eight engines driving contrarotating propellers, it was similar in scale and conception to the Hughes H-4 “Spruce Goose.” Both remain curiosities, because the era of the flying boat ended with the war, when intercontinental travel became the province of fast Douglas and Lockheed landplanes. As Stuka designer Hermann Pohlmann later remarked, “Speed made comfort superfluous.”

In March 1944, the first—and only—BV-238 lifted off from the Elbe River beside the B&V plant. By that time, Allied fighters had secured air superiority over Germany, and flight testing had become a more than usually perilous business. Some B&V facilities had been heavily bombed, and the rest were under constant threat. Nevertheless, the gigantic airplane, sheltering between flights under heavy camouflage on a nearby lake, managed to survive until the following spring, when it was detected by Allied fighters, strafed and sunk.

Two other, smaller projects were begun late in the war, but never progressed beyond early flight tests. One, the BV-40, was a glider intended to be towed to altitude by an Me-109 to attack Allied bomber formations from above. Oddly, considering the cultural differences between Japan and Germany, Vogt initially envisioned kamikaze-style ramming tactics. The RLM rejected this idea, demanding a nose cannon instead. Tiny, with a wingspan of 25 feet, a diving speed of 550 mph and its pilot lying prone in a pencil-thin fuselage behind a 5-inch-thick tank window, the BV-40 would have been a difficult target for Allied escort fighters. Several were built and test-flown in the spring of 1944, but the RLM viewed them with little enthusiasm and, as luck would have it, all examples, both finished and incomplete, were destroyed in their factory in an October 1944 bombing raid.

Another project, technically more ambitious, was the BV-155, which B&V took over from Messerschmitt. The original plan, for a fighter called the Me-155A intended to operate at 50,000 feet, had been conceived by Messerschmitt as a simple modification of the 109, with an extended wingspan and a more effective supercharger. Vogt insisted on starting more or less from scratch. The result, built in just nine months, was a striking airplane with a wingspan of 67 feet, a turbocharged 1,800-hp engine and two large radiators located midspan on the wings. It took fewer than a dozen test flights to reveal that keeping a reciprocating engine happy at 50,000 feet was not as easy as it looked.

In addition to manned aircraft, B&V developed several Flugkörper, or unmanned aircraft, of which hundreds of examples were built. These were personal projects of Vogt’s in which the RLM evinced little interest. The first of them, begun in 1939 and eventually abandoned in 1943, was an anti-ship missile carrying a 1,100-pound warhead. It was designed to be launched from an airplane, accelerated to 450 mph by a small rocket motor and then to glide to its target.

The second, the BV-950, was a glider airframe designed to be attached to a conventional marine torpedo. This contraption—made entirely of steel—arrived too late to be of use; 584 were built in 1944-45, but the destruction of the factory and the imminent collapse of the German military brought the project to an end.

The third, a pure glider bomb, was a very simple and aerodynamically elegant design, similar in appearance to a modern sailplane, with a clean, shoulder-mounted 21-foot wing of very high aspect ratio and a teardrop-shaped round fuselage. With a glide ratio of 25-to-1, it could fly 100 miles from a launch altitude of 21,000 feet. Like the torpedo carrier, this design, a potential competitor to the V-1 buzz bomb, arrived too late in the war to have any practical application.

With the exception of the asymmetrical BV-141, the aircraft actually manufactured by B&V did not reflect the real inventiveness of Richard Vogt. During the war’s final years, he developed many “project” designs. One, the P.163, carried the idea of the 141’s view-improving offset nacelle to the extreme—placing pilot, observer and gunners in nacelles at the tips of the wings. Another, the P.170 high-speed bomber, mounted three radial engines, one in the center and one at each wingtip, and placed the cockpit behind the bomb bay, at the very tail.

Vogt greeted the arrival of the jet engine with several novel designs, including a four-engine bomber and several single-seat fighters, one of them featuring a steeply forward-swept wing. He understood the value of wing sweep for transonic drag reduction, which had originally been described at an aerodynamics conference in Italy in 1935 but which eluded the Allies until the U.S. began importing German scientists and engineers after the war. Remarkably, Vogt also proposed a variable-geometry “scissors wing” design, the P.202, in which the entire wing rotated into an X-shape with respect to the fuselage. Half a century later, a NASA study of exactly this concept led, through the construction of a scaled-down test model at Mojave, to the founding of Burt Rutan’s now famous prototype shop, Scaled Composites.

B&V and HFB—always the same firm, under two names—survived the war. Today Blohm+Voss, its quaint ampersand replaced by a hip-looking plus sign, continues to produce ships and private yachts. HFB remained in the hands of the Blohm family until 1969, continuing to produce various airframes, including its own Hansa business jet, remarkable for the use of a swept-forward wing. HFB was then merged into Messerschmitt-Bölkow-Blohm, and, most recently, has formed part of the Airbus Consortium.

At the end of the war, Richard Vogt became one of the “Operation Paperclip” immigrants from Germany to the United States. He worked initially for the Air Force and later for Boeing, eventually retiring to Santa Barbara, Calif., where he died in 1979.

Los Angeles–based aviation writer Peter Garrison has built two airplanes of his own design. Further reading: Blohm & Voss Bv 138, by Heinz J. Nowarra; Blohm & Voss Bv 141, by David Myhra; and Blohm & Voss Bv 222 Wiking, by Rudolf Hofling.

This story was published in the May 2017 issue of Aviation History magazine. Subscribe here.