The fires of World War II forged many of the technological advances that have transformed our world in the more than half century since. One of the most important was the development of the gas turbine, or jet engine—a development usually associated with Germany. This is largely because various German jet aircraft (along with one almost forgotten British jet fighter) actually flew combat missions during the war. And there is no denying the appeal of many of the German designs, especially the sleek and deadly Messerschmitt Me-262.

Almost unknown by comparison, but arguably more important to the future of aviation, were the jets developed in the United States during the war. Although no American jet actually saw combat in the conflict, the United States was responsible for initiating more jet fighter designs at that time than any other nation save Germany. Unlike the Luftwaffe’s projects, which were usually intended to be futuristic, war-winning “wonder weapons” but frequently fell far short of hoped-for capabilities, American jet projects were almost invariably more practical and effective. The experience gained in their design and production laid the foundation for the creation of today’s most advanced combat aircraft.

American engineers and designers had been aware of the theoretical potential of gas turbine propulsion for some time prior to WWII. But no practical development work on such an engine had been done in America, at first because of the tight budgets of the Depression era and later because there were no resources to spare from the task of building enormous numbers of conventional fighters for the rapidly expanding U.S. Army Air Forces.

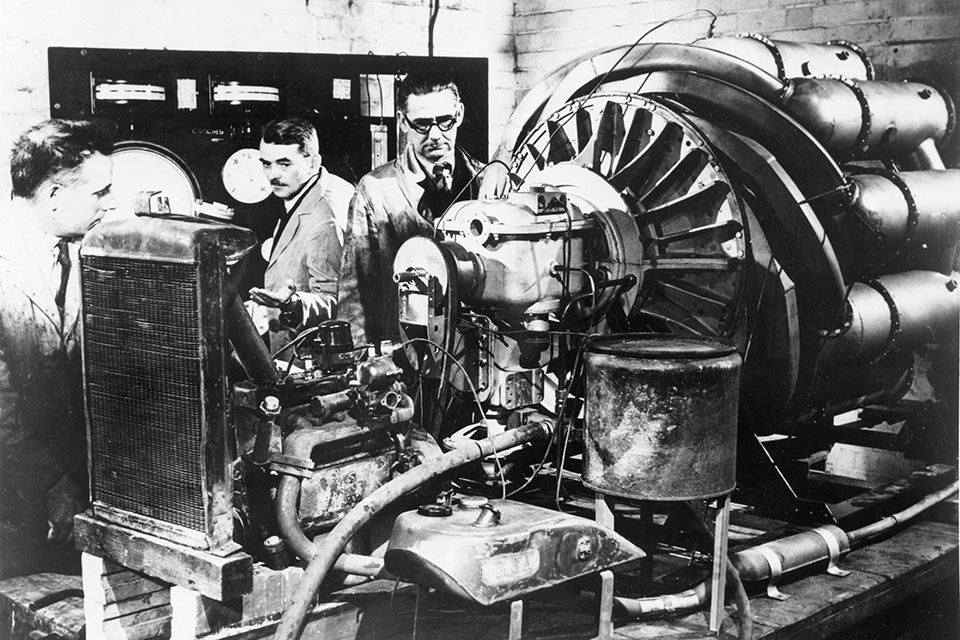

The first practical design for a jet engine came from England. Flying Officer Frank Whittle, a serving officer in the Royal Air Force (RAF), patented his design for a jet engine in 1930, but his invention encountered disbelief and opposition from his government and the British aviation industry. Whittle eventually formed his own design company, Power Jets Ltd., to prove the feasibility of his new engine. Operating on a shoestring budget in an abandoned factory, Whittle succeeded in producing several functional static test models of his engine shortly before the war began. That was enough to overcome at least some of the initial resistance to his ideas, and prompted the RAF to build an experimental aircraft to test Whittle’s engine.

Those developments were unknown in the United States when Maj. Gen. Henry H. “Hap” Arnold, the commanding officer of what at the time was the Army Air Corps, visited England in the spring of 1941 to confer with the British. While there, Arnold was briefed on the new engine and test aircraft, and also inspected the aircraft and witnessed some short test flights. Deeply impressed, he decided that the United States should develop the new engine technology as well. Trading on the desperate need of the British for American support in the war effort, Arnold was able to secure not only the complete plans but also several examples of the top-secret aircraft engine for testing.

The U.S. commitment to developing jet propulsion was not due to any perceived threat. Although the Germans were indeed working on jet fighters at that time, their designs were both highly secret and conducted at a rather leisurely pace. It would be several years before the Allies began to receive information on German jets.

Arnold’s first task was to entrust the development of the new engine to an appropriate manufacturer. He refused to give the job to one of the already established aircraft engine builders such as Allison, Wright or Pratt & Whitney—in part because they were already working at full capacity to fill the demands of a rapidly expanding Army Air Corps, but also because he did not want the project to be bogged down by conventional thinking. Instead he turned to General Electric, which not only had a reputation for innovation but also had considerable experience in producing superchargers, which used technology similar to that of jet engines. “Gentlemen: I give you the Whittle Engine,” he reportedly told GE. “Consult all you wish and arrive at any decision you please—just as long as General Electric accepts a contract to build fifteen of them.”

The decision as to which manufacturer should build the Army’s first jet fighter was complicated by the fact that almost all of the country’s aircraft firms were already working at capacity to fill existing government contracts. There was one that had some unused capacity—Bell Aircraft of Buffalo, N.Y., whose reputation as the designer of the unorthodox P-39 Airacobra was a plus, as was its proximity to GE’s Schenectady facility, where work on the new engine was being done. Lawrence Bell, the company’s president, personally requested the privilege from Arnold, and on October 3, 1941, Bell was given a contract for three prototypes.

The result of that contract was the first of the super-secret design facilities that have since become the norm. The entire project was classified as “special secret,” the highest of the various secret classifications employed by the government. Secret did not necessarily mean well equipped, however. Since government security regulations prevented the company from using its regular facilities for the work, the top floor of a Ford dealership in Buffalo was requisitioned to serve as the design facility. A separate entrance was built, and military guards were detailed to protect the location. The second-floor windows were welded shut and painted black. To work in this rather gloomy space, Bell put together an elite design team that became known as the “Secret Six.”

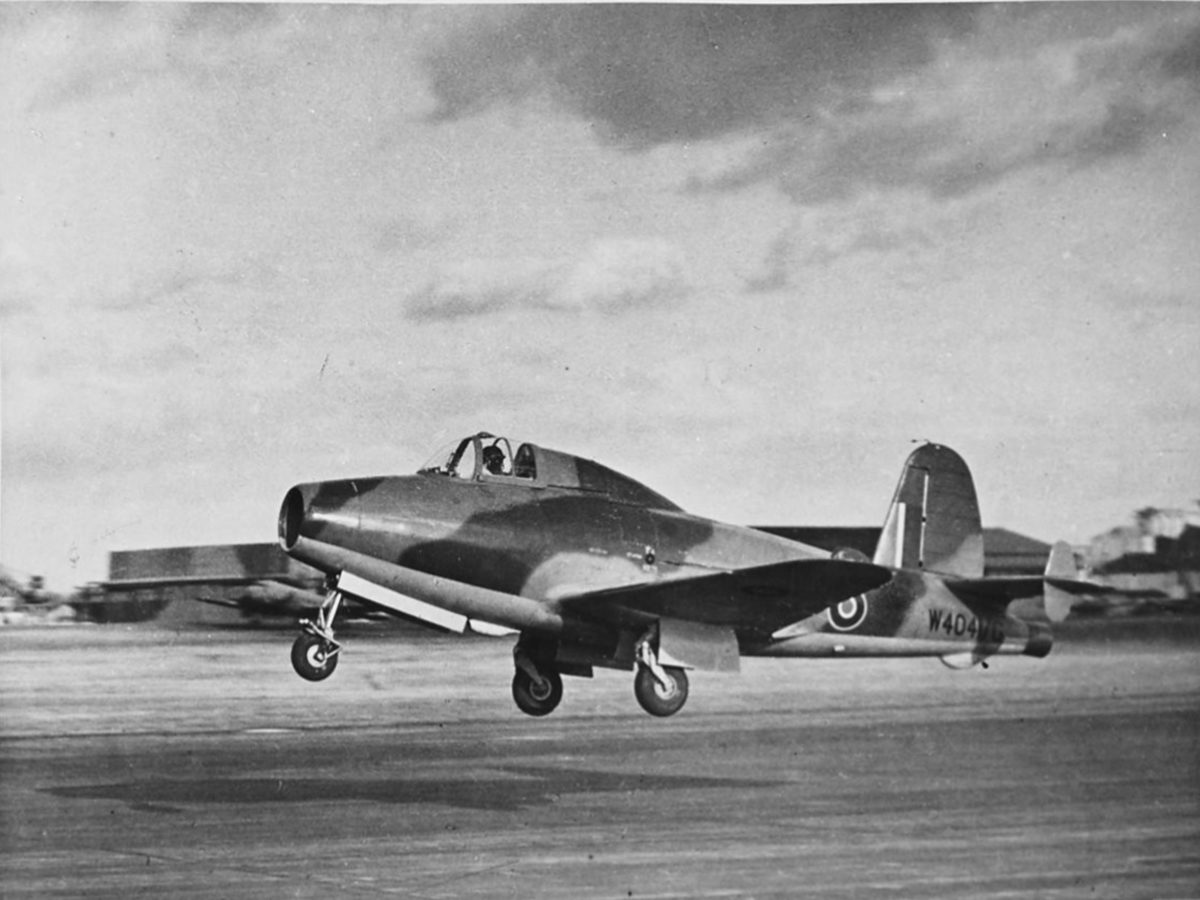

Even the plane’s designation, XP-59A, reflected the secrecy surrounding the whole effort. Bell had earlier worked on a pistonengine ground-attack aircraft, to which the Army had assigned the designation XP-59, but lost interest while it was still in the conceptual stage. When Bell obtained the jet fighter contract, the designation was simply resurrected and modified to shield the project.

The task faced by the Secret Six was daunting in the extreme. First, the team was supposed to produce a fully functional combat aircraft, not simply an experimental test machine, such as the British jet Arnold had observed. That meant including a number of weight-adding features necessary for combat, such as armor protection for the pilot, self-sealing fuel tanks, and weapons and ammunition. Far more serious was the fact that the design team had virtually no information about the power plant around which they were supposed to be designing the airframe. All the designers had were a few outline drawings of the engine, some basic dimensions and a very rough estimate of its hoped-for performance. Those performance estimates suggested that it would produce a very limited amount of power. Even with two engines, they feared the XP-59A could easily end up being seriously underpowered.

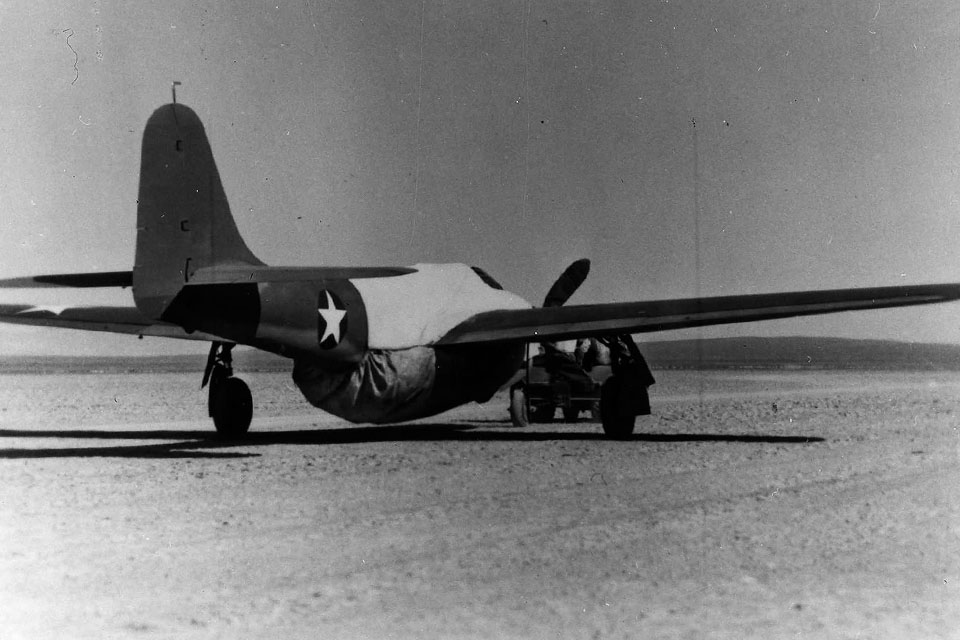

The jet produced by the Bell team was in most respects a conventional and graceful design, although placing the two rather bulky engines on the outside of the bottom of the plane gave it a pot-bellied look. There were several special features intended to allow the plane to function at high altitudes, such as oversized wings and cockpit pressurization. In addition, the new low-drag laminar flow wings were incorporated. GE had not yet finished producing a functional version of the Whittle engine, but with the arrival of a pair of engines from England in August 1942, the XP-59A, christened the Airacomet, was ready to take to the air.

The Airacomet was first tested at the Muroc Bombing and Gunnery Range, at Muroc Dry Lake and Rogers Dry Lake, Calif. This was an ideal testing arena with the enormous, flat, dry lakebeds providing excellent landing for a plane with unexpected problems. Located in the heart of the Mojave Desert, far from potentially unfriendly eyes, the site would eventually become Edwards Air Force Base.

GET HISTORY’S GREATEST TALES—RIGHT IN YOUR INBOX

Subscribe to our HistoryNet Now! newsletter for the best of the past, delivered every Monday and Thursday.

Of course, the fact that the Airacomet had been built in New York meant that the entire plane had to be disassembled and shipped by rail across the country before it could be tested. The aircraft and those traveling with it endured a journey worthy of a Three Stooges film. Highlights included leaving various members of the team behind at different stops, having one of the cars carrying part of the aircraft go missing in a switching yard, and nearly being hijacked by a small group of armed men. The armed men turned out not to be enemy saboteurs but U.S. Marines, assigned to guard a car carrying explosives that was connected to the cars carrying the new jet fighter. Eventually the Airacomet and its weary guardians reached their destination, the aircraft was reassembled and testing began.

The Airacomet prototypes experienced the usual various minor problems and glitches that are inevitable with any new aircraft, but the jet engines proved to be especially troublesome. The untried and unfamiliar jet engine technology meant that everyone involved in the testing process had to learn a new set of rules, such as not getting too close to the exhaust stream of an operating jet engine.

According to one accident report: “Bell Inspector E.F. Fisher, weighing 200 pounds, walked into the jet approximately four feet behind the nozzle while the aircraft was operating at rated power. It lifted him approximately 3 feet in the air, tumbled him end over end approximately 3 times, and he made a facedown landing on the concrete approximately 25 feet behind the nozzle exit. No substantial injuries were sustained other than brush burns obtained upon contact with the concrete surface.”

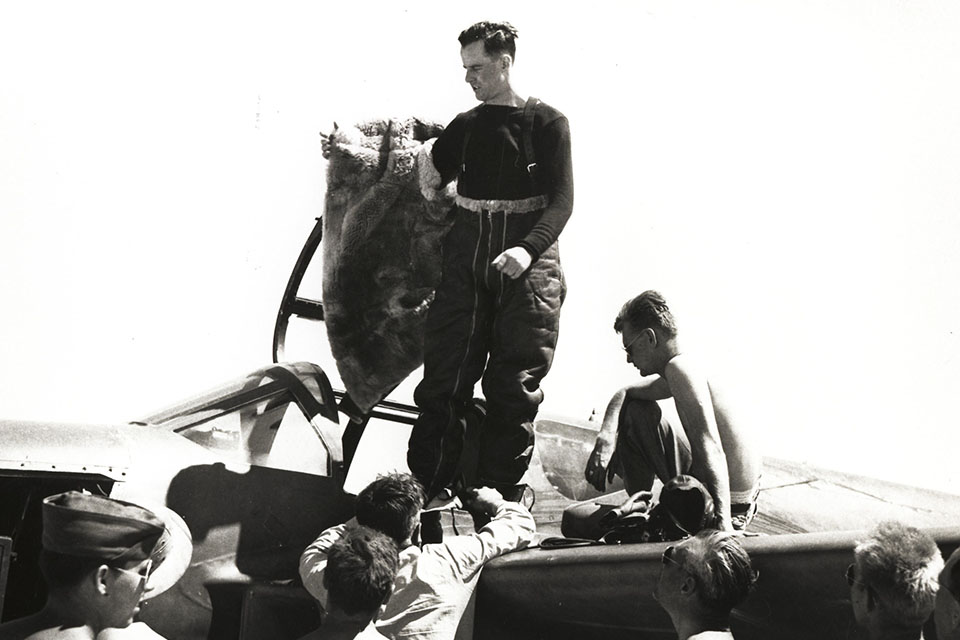

Testing of the Airacomet was conducted under the same security blanket that had covered the entire project. The consequences varied from nearly lethal to ridiculous. During one test flight, a sudden sandstorm blew up, and visibility instantly dropped to zero. Forbidden from flying to a public airfield, Jack Woolams circled the test site, hoping for the storm to lift. When he ran out of fuel, however, Woolams showed why test pilots are the best in the business by making a perfect dead stick landing in zero visibility.

On another occasion, when the Airacomet had to be towed through an area where civilians might see it, security was ramped up to new heights. The plane was covered with tarpaulins, and an enormous wooden, fake four-blade propeller was fitted to the jet’s nose. In addition to looking more than a little ridiculous, such measures may actually have piqued the interest of observers, who would probably have otherwise ignored the transfer of another military airplane.

Flight-testing of the P-59 prototypes revealed that the plane had generally acceptable, even pleasant handling characteristics. One of the few performance flaws was potentially serious, however. The nose of the aircraft “snaked” from side to side at high speeds, making it impossible to hold the guns on a target. This problem, while significant, could probably have been overcome, if not for another even more serious flaw.

The apprehensions of Bell and his design team about the relatively low power of the new engines turned out to have been well founded. Although efforts were made to increase the power output, the plane’s design limited the size of engine that could be used. Even with the most powerful engines available, the Airacomet was barely able to exceed 400 mph in level flight. Since a number of the most recent piston-engine fighter planes were already faster than that, there was little point in producing it for combat.

Testing of the P-59 would continue for a considerable time, largely to gain knowledge about jet engines and aircraft. Later testing was conducted under much more relaxed security, which gave test pilots an opportunity to indulge their sense of humor. One day, for example, a pilot returned to the nearby Army Air Forces training base with an incredible story: Another aircraft, one with no propeller, had flown next to his, piloted by a gorilla wearing a derby hat and smoking a cigar. The hapless pilot was soundly denounced as a shameless liar, but the “bogey” turned out to have been a P-59 flown by Woolams, wearing a Halloween costume and indulging in his passion for cigars.

The P-59 was an ambitious design and the Bell engineers did a commendable job in producing America’s first jet fighter. Bell ultimately produced 50 Airacomets, used primarily for jet transition training. From its earliest flight-testing of the P-59 in the fall of 1942, however, the aircraft clearly lacked the performance advantage the Army was hoping for in a jet fighter. That prompted the Army to select another company to build its breakthrough jet fighter: Lockheed Aircraft Corp.

Based in Los Angeles, Lockheed had a reputation for both innovation and high performance in its designs. In addition, Lockheed—and especially chief aircraft designer Clarence “Kelly” Johnson—had previously demonstrated an interest in jet aircraft. Johnson had produced a design in 1940 for a radical and extremely advanced jet fighter aircraft, as well as the engine to power it. The Army rightly decided that the design was too complex and would require too much development time to be worthwhile (the estimate was four years), but when a successor to the P-59 was needed, Army leaders remembered Johnson’s interest in building a jet fighter.

While Johnson was observing armament trials for his P-38 Lightning design in May 1943, he was approached by Army representatives about producing a fighter to be powered by the latest British jet engine. He was so excited about the prospect that he began preliminary design work during his flight home, and even began making arrangements for the construction of a prototype.

Johnson demanded and received permission to recruit anyone he wanted in the company to work on the new fighter. Like the members of Bell’s design team, they needed to work in secrecy. The Lockheed jet project was housed in a crude structure hurriedly constructed of two-by-fours, plywood and tar paper, and located next to the company’s wind tunnel facilities.

The hurried and highly secret nature of the project left some issues unaddressed—for example, what to call the whole thing. When one of the project’s engineers, Irving Culver, was assigned to answer the telephone one day, he realized that he could hardly say, “This is Culver at the super-secret jet fighter project.” Culver was a fan of Al Capp’s comic strip “Li’l Abner,” set in the tiny mountain town of Dogpatch, which had a moonshine still. The still’s proprietors jealously prevented anyone else from entering, in order to guard their secret formula. The still was known, in Capp’s idiosyncratic spelling, as the “Skonk Works,” after at least one of the ingredients in the brew. Making a natural connection, and in the absence of any other instructions, Culver decided to answer the phone with “Culver, Skonk Works.” Thus was born the most famous of the supersecret aircraft design bureaus, Lockheed’s Skunk Works, which would go on to produce many highly successful and influential aircraft. Johnson hated the nickname, but he was unable to prevent people from using it. He eventually gave in to the inevitable and formalized the name.

Only a month after being approached by the Army, Johnson and his team had a detailed enough proposal to present. The design promised to be simple and sturdy, yet have the performance the Army was looking for. To further sweeten the deal, Johnson promised to have a flyable prototype ready for testing in the almost unheard-of time of 180 days. Impressed, the Army told him to proceed. Johnson returned to California and went to work.

The new prototype fighter, which would be designated the XP-80, was to be powered by a British-built Halford Goblin engine. Production models would have a more powerful, American-built version of that engine. Like the XP-59A, the XP-80 was to be a fully functional fighter, designed from the outset with armament, armor and self-sealing fuel tanks. Unlike Johnson’s earlier radical experiment with jet fighter design, the P-80 broke little new ground. A low-drag laminar flow wing was incorporated, but it had few other innovative features. The engine was mounted in the center of the fuselage, and the intake ducts were located on either side of the nose. One new feature, added in anticipation of the forces from the airflow at high speeds, was hydraulic assist for the control surfaces, as already successfully introduced in the P-38J and P-38L.

Lockheed had a mockup to present to the Army in July 1943. Work proceeded so rapidly, in fact, that by late August it could progress no further without the actual engine, scheduled to arrive from England at the beginning of September. Various delays prevented the engine from reaching Lockheed’s factory until the beginning of November. These delays, plus a desire to test various components left off the initial prototype to hasten its completion, prompted Lockheed to ask for permission to construct two additional prototypes, designated as XP-80As, to be powered by the larger and more powerful American version of the engine, General Electric’s I-40. Showing the progress made by GE with jet engines in less than two years, the I-40 was rated at 4,000 pounds of thrust, compared to the 1,200 pounds of the I-A used in the first XP-59A.

Despite the delays with the Goblin engine, the first P-80 prototype, nicknamed Lulu-Belle and painted a nonstandard glossy dark green, was ready to fly within the specified 180 days. The Army showered praise on Lockheed for its accomplishments and eagerly awaited the results of the flight-testing.

Recommended for you

Like the Airacomet, Lulu-Belle was to be tested at Muroc. Delays ensued, including one that was the result of a very serious problem. During a final preflight engine check, the engine was run up to full power. This caused the intake ducts to collapse inward, and almost sucked Johnson into the engine as well. The collapsing ducts had shed bits of metal into the engine, so it was decided to disassemble it to check for damage. Although no damage from the ingested metal was found, another serious problem was discovered. The impeller vane, which drew air into the compressor to begin the power cycle, had a large crack in it, resulting from problems in its forging. That flaw could have led to a catastrophic inflight failure with lethal consequences, so the accident turned out to be a blessing in disguise. Since the impeller was a single unit and could not be repaired, a new engine was shipped from England, and the intake ducts were repaired and strengthened.

Lulu-Belle was finally ready for its first flight on January 8, 1944. A small crowd of engineers, mechanics and government representatives gathered under cold, gray skies. Johnson had some final instructions for Lockheed’s chief test pilot, Milo Burcham: “Just fly her Milo. Treat her nice—and find out if she’s a lady or a witch.” Burcham gradually eased in the throttle, and Lulu-Belle sped across the lakebed. As the plane reached 110 mph, Burcham gently took off, but minutes later, to the disappointment of all present, Lulu-Belle was back on the ground. Burcham had been unable to get the landing gear to retract. The problem was simple enough—a safety lock had recently been installed to prevent the accidental raising of the landing gear, but Burcham had not been told about it.

With the problem resolved, Burcham gently lifted Lulu-Belle from the lakebed once again. The landing gear retracted with no problems, but as Burcham climbed away to perform some preliminary tests, the crowd’s anxiety was palpable.

Suddenly, Lulu-Belle dived out of the gray desert sky toward the crowd. Reaching speeds of up to 490 mph during his descent, Burcham pulled out of his dive scant feet above the desert floor. He leveled off and pushed the throttle to the wall, and made a screaming high-speed pass over the crowd. Flashing over the stunned observers at 475 mph, Burcham pulled up into a steep climb, doing a series of dazzling aileron rolls. As the crowd erupted into joyous bedlam, there was no longer any doubt in the minds of those watching—Lulu-Belle was every inch a lady!

The Army was thrilled with Lulu-Belle’s performance and lack of obvious handling problems, and immediately placed an order for 500 production aircraft with Lockheed. It was expected that the P-80 would begin entering squadron service in the summer of 1945. In fact, the Army was so excited by the demonstration that by May 1944 it was holding talks with Lockheed about the expectation of producing 450 P-80s per month by the summer of 1946.

Lulu-Belle continued its flight-testing, and was soon joined by the two additional XP-80A prototypes. The more powerful American-built engines required somewhat larger and heavier aircraft, although they looked very similar to Lulu-Belle. The first was painted light gray overall and given the name Gray Ghost. The second was left in bare metal and dubbed Silver Ghost. In it an additional seat was installed behind the pilot’s seat, so that an engineer could ride along and record test data that the pilot was too busy to handle.

Following the three prototypes, 13 additional preproduction YP-80s were built. While undergoing testing, four YP-80As were selected to participate in Project Extraversion, a response to the increasing presence of German jet fighters in the skies over Europe. Two YP-80s were sent to the Mediterranean theater and two to England, where they traveled to various air bases, made demonstration flights and proved to the troops that the United States had some of its own new high-performance jet aircraft.

As testing of the various P-80 prototypes continued, serious problems developed. All new aircraft have their share of problems, and the purpose of flight-testing is to identify and fix them. But the high speeds of the P-80—even more so with its new American-built jet engines—would produce lethal problems that demanded solutions before the program could continue.

A fuel pump failure shortly after takeoff on October 20, 1944, led to an engine flameout that resulted in a crash, killing Burcham. This prompted the installation of backup electric fuel pumps in the other aircraft. Burcham’s replacement as chief test pilot, Tony LaVier, was also involved in a disastrous accident. While he was flying a highspeed test in Gray Ghost, there was a loud noise, and the entire plane began to pitch and roll violently through the sky. Taking to his parachute, LaVier observed Gray Ghost falling through the sky near him—missing its entire tail section.

It was determined that the turbine wheel in the engine had come apart, shedding blades that had literally sawed off the tail. The problem was traced to flaws in the steel used to manufacture the wheel, leading to much more stringent quality control measures in the engine manufacturing process.

Other fatal crashes stemmed from a variety of causes. Many factors contributed, from the need for more exacting production standards for the high-performance aircraft to inexperience on the part of the pilots, most of whom were accustomed to the very different performance of piston engines. The first production models of the P-80, now known as the Shooting Star, were eventually all recalled for various fixes. What would become the most notorious crash came on August 6, 1945, when one of the early production Shooting Stars was taken up for its initial acceptance flight by Major Richard I. Bong, the American ace of aces, with 40 kills—all scored in the Pacific while flying another Lockheed aircraft, the P-38 Lightning. On takeoff, the P-80 lost power and crashed, killing Bong instantly.

Bong’s death—occurring on the same day as the dropping of the atomic bomb on Hiroshima—emphasized the fact that for all its remarkable performance, the P-80 still needed time to work all the bugs out, and that its pilots needed to become familiar with a power plant that was very different from the big piston engines they were used to. Had the United States been in the same desperate straits as Nazi Germany, the P-80 would have undoubtedly been rushed into combat, bugs and all. But since the Allies were well on their way to total victory, there was no need to push the P-80 into service prematurely. Given plenty of time to finish its development, the P-80 went on to a very respectable career in the Air Force, and also gave outstanding service in another conflict, the Korean War.

Although the P-59 and the P-80 were the only American jet fighters to attain production in the 1940s, others were built for testing, and several would continue development after the war.

The first of the various prototypes built during the war was not primarily a jet, but made use of jet propulsion to enhance performance. Newcomer McDonnell Aircraft produced a sleek twin-engine propeller-driven bomber interceptor, the XP-67 Moonbat, which used two small jet engines in the rear of the piston engine nacelles to give additional thrust. Although the Moonbat never achieved production, it was an interesting attempt to enhance traditional propeller-driven performance with jet propulsion.

As soon as actual flight testing began, it became apparent that jet engines consumed fuel in staggering amounts, even using their most economical fuel settings. That dilemma of jet fighter design— higher speed versus shorter range—has confronted designers ever since. During the war, this range factor presented the Army with a serious difficulty. The core of the Army Air Forces’ doctrine was using long-range heavy bombers to attack the enemy’s resources and production, an effort largely made possible by the timely arrival of the superb North American P-51 Mustang fighter, which had the range to accompany the bombers all the way to their targets.

With the Germans beginning to deploy their jets to attack Allied bombers, however, a new problem became evident. Tests with P-59s and P-80s quickly proved that the only practical way to combat a jet was with another jet. So the Army laid out a new requirement: Come up with a jet design that had the range of a piston-engine plane like the P-51 but could fight at jet speeds.

The first company to take up that challenge was Bell Aircraft, eager to redeem itself after the failure of the P-59. Drawing on its experience with the earlier design, the Bell team used much more powerful engines to produce what became known as the P-59’s “big brother,” the XP-83. With a fuselage carrying more than 1,000 gallons of fuel, and even more in external drop tanks, the XP-83 did indeed have the range to accompany the bombers. But the plane’s huge size meant that its performance was only marginally better than piston-engine fighters, and inferior to other jet designs.

The other entry into the long-range jet competition came from Consolidated Vultee, which took a different approach to the range versus speed issue. While the XP-83 had used two large jet engines, the XP-81 used a small jet engine in the nose to drive a propeller, and a larger jet engine in the tail. The rear engine was supposed to give extra power and speed for takeoff and combat, with the turboprop in the nose used for long-distance cruising.

A sleek and graceful plane despite its size, the XP-81 was tested extensively. While it achieved the basic performance its designers had hoped for—long range and high combat speeds—like the XP-83, its performance was again only marginally superior to piston fighters, and therefore insufficient to justify production. In addition, both the XP-81 and XP-83 reached the testing stage very late in WWII, when the urgent need for a long-range jet escort had essentially vanished.

Most American wartime jet fighters were very conventional compared to such innovative and futuristic German jet concepts as fixed and variable sweptwings, forward-sweptwings, delta wings, flying wings, pulse jets, ram jets and rocket propulsion. The most notable exception was conceived by John K. “Jack” Northrop.

Northrop’s design, the XP-79B, was originally intended to be rocket-propelled, much like the German Messerschmitt Me-163 Komet. Problems with development of the rocket engines led to a switch to jet propulsion instead. Northrop then crammed as many innovations as he could into the aircraft.

The most obvious was the use of the “flying wing” concept as a basis for the design. Studies had indicated that an all-wing surface would be the most efficient possible aircraft design, and this design concept fascinated Northrop. The Germans produced a jet flying wing, the Horten/Gotha Go-229, which made limited test flights before the end of the war. But Northrop took the flying wing concept even further. Unlike the German design, which had no vertical tail surfaces, the XP-79B had two fixed vertical stabilizers. Instead of rudders, however, the XP-79B had a pair of hollow tubes located on the wingtips. Movable vanes inside the tubes, or bellows, would alter the airflow and move the nose from side to side.

Most aircraft had begun to use a tricycle landing gear design—two main wheels under the wings and a wheel at either the nose or tail. The XP-79B had four wheels, two outboard each of the pair of jet engines, intended to give the plane stable handling on the ground.

Even the plane’s construction was unorthodox. By WWII, aluminum was the standard construction material for combat aircraft, although a few designers also used wood composites. The XP-79B, however, was built of magnesium, which is both lighter and much stronger than aluminum. Its durability even led the Army to consider using the XP-79B as a flying ram, to literally cut enemy aircraft out of the sky, until common sense prevailed and that idea was dropped. The magnesium added greatly to the difficulty of building the airplane, however, as no one had ever used the metal in such a fashion before, and techniques for shaping and welding it had to be developed.

If all that was not enough, the XP-79’s design specified that the pilot would lie on his stomach, looking out of a small bubble canopy located between the two engine intakes. This prone position was intended to give the pilot greater ability to tolerate the high G forces encountered in high-speed maneuvers. Studies had shown that a seated pilot could tolerate no more than 5 or 6 Gs before blacking out, while a prone pilot could handle 9 or 10 Gs before losing consciousness.

Combining all those design elements into a single package, the XP-79B was a graceful if rather odd-looking craft. Unfortunately, during its first flight, pilot Harry Crosby lost control of the aircraft, ironically due to what was reportedly a jammed aileron rather than any of its novel features. Crosby bailed out but was killed by the plane hurtling to the ground. Since magnesium is highly flammable, the XP-79B was consumed in flames after it crashed. It was the only prototype, and no further work was done with the project.

Design work was begun on two more jets during the war. In 1944 the Army asked Republic Aviation to develop a new fighter design using a new type of jet power plant, an axial flow engine. All previous American jet engines had been, like Whittle’s first designs, centrifugal flow. In a centrifugal flow engine, the air entered through a large central compressor, was channeled outward into a ring of several small combustion chambers, and then channeled inward again to exit through a central exhaust chamber. The airflow pattern was essentially a double “S” flow, and as a result those engines were short and compact, but quite wide and therefore very bulky for their length.

An axial flow engine used a number of smaller sequential compressors and a central combustion chamber, resulting in a linear airflow. This design produced an engine longer and much more slender and streamlined than a centrifugal flow engine. Republic’s P-84 Thunderjet, built around this new engine, was not ready for flight-testing until January 1946, but it would eventually become a mainstay of the postwar Air Force as well as the premier fighter-bomber in the Korean War.

One other aircraft company decided to try its hand at jet design late in World War II. North American Aviation’s initial results produced a design quite similar to Republic’s P-84, and so were of little interest to the Army. So the designers of the legendary P-51 Mustang went back to the drawing board, inspired by data from captured German records. It took a couple of years to get everything working properly, but when North American’s engineers finished their design, they had a real winner. The Air Force enthusiastically tested and accepted the last of the American WWII jet fighter designs—the F-86 Sabre, which would find fame in the skies over Korea a few years later.

The United States, far from being left behind in the field of jet propulsion, was in fact out in the forefront of its development during World War II. Lacking the glamour of many of the German jet designs, American jets tended instead to be practical and functional aircraft. And while the many exotic German jet designs seemed to point to the future of aviation, it was the solid and dependable American designs that laid the real foundation for the jet revolution.

Thomas J. Goetz, who writes from Stafford,Va., recommends for further reading: Flame Powered: The Bell XP-59A Airacomet, by David M. Carpenter; and E.T. Wooldridge’s The P-80 Shooting Star: Evolution of a Jet Fighter.

Originally published in the September 2006 issue of Aviation History. To subscribe, click here.