Expectations were high when Burt Rutan teamed up with Beech to produce the Starship business aircraft, but the result was a rare failure for the innovative designer.

In 1955 the Beech Aircraft Company considered marketing the French Morane-Saulnier MS.760 Paris jet in the United States. On learning that it was necessary to step over a side rail in order to enter the aircraft, president and chairwoman Olive Ann Beech, whose relationship to the company founded by her late husband resembled that of a queen to her subjects, decreed that there were to be no Beech aircraft that a lady could not enter with modesty and dignity. Since at the time the Paris was the only jet being offered to private owners, her ukase became known as the “no jets” rule.

In consequence of the no jets rule, Beech Aircraft Corporation went on to become the dominant manufacturer of twin turboprops for business and personal use. Its King Air, which went on the market in the same year as the first Learjets, accounted for about half of all twin-turboprop sales.

By 1979, however, the King Air, then 15 years old, was getting long in the tooth, and Cessna’s light Citation jet was nibbling at its sales. Beech engineers began to contemplate a more modern, higher-performance twin turboprop. The requirement was straightforward: an eight-passenger turboprop that would weigh less than 12,500 pounds—to keep it in a desirable FAA certification category—and do 350 knots, or about 400 mph. The study had not gone far, however, when Mrs. Beech sold the company to defense conglomerate Raytheon.

During the management transition that followed, the design study, called NGBA for Next Generation Business Aircraft, languished. Work on what would become the Beech Starship did not resume until 1981.

But the story of the Starship really began years earlier, and far from Beech’s Wichita headquarters, in a ramshackle ex-Army barracks at Mojave Airport in the southern California desert. There, an unknown aeronautical engineer named Elbert “Burt” Rutan built a two-seat airplane that he called the VariEze. It was a dramatic-looking thing, with raked fins at the tips of slender swept wings and a smaller, straight horizontal surface at the front of a narrow fuselage in which two people sat in tandem. Behind them, a modified Volkswagen engine drove a little wooden propeller. The VariEze was sleek and fast, and when it flew overhead you felt that you were seeing the future.

Rutan sold plans for the VariEze and for a slightly larger successor, the Long-EZ, to amateur builders. For a time they were the best-selling homebuilt types on the market, and they triggered a “canard revolution” during which a good many new designs from all over the world used the same sweptwing, tail-forward, pusher-propeller formula. Rutan, who did not shy away from publicity, became a familiar character in the aviation press, usually introduced as “canard guru Burt Rutan.”

Beech engineers were aware of Rutan’s designs, and one of the configurations discussed for the NGBA was a canard. Pusher propellers mounted at the trailing edge of the swept wing, well behind the cabin, seemed to promise a reduction in cabin noise. The engineers also apparently believed that eliminating the tail cone might yield an airplane with less surface area. Since much of an airplane’s drag is due to the friction of air against its skin, reducing surface area is one avenue to increased performance.

In mid-1982, Beech let a contract to the Rutan Aircraft Factory for a feasibility study and configuration proposals for the NGBA. Rutan delivered at least two proposals. One was a canard very similar in appearance to the VariEze, another a three-surface airplane similar to the Piaggio Avanti, which was under development in Italy at the time and to which the Starship would later be unfavorably compared.

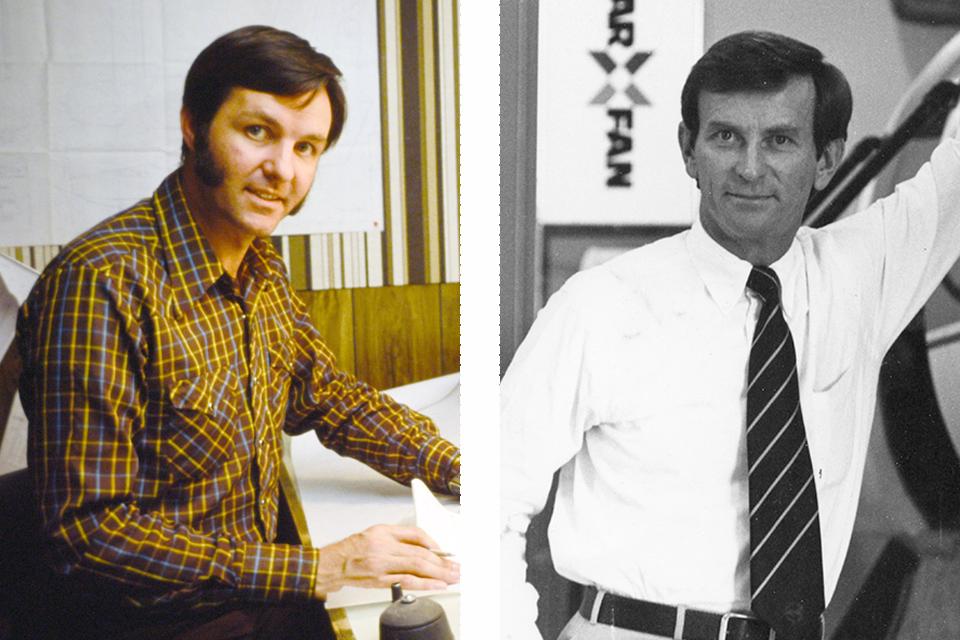

In the meantime, Raytheon had hired Linden Blue, a businessman with ample aeronautical experience, as president and CEO of Beech. Before his hiring had been publicly announced, Blue called Rutan, whom he knew, and asked him about the NGBA, which Rutan had been instructed to keep in extreme secrecy.

“How do I know you’re really with Beech?” Rutan coyly replied.

Shortly afterward, Blue called a meeting that has come to be known as the “beauty pageant.” Beech engineers expected the Rutan proposals to be one part of a wide-ranging discussion, but it didn’t turn out that way. Beech’s new president pounced on the VariEze-like design, and before the meeting ended he signed a contract for a second phase that required Rutan’s newly formed company, Scaled Composites, to deliver an 85-percent-scale flying prototype for aerodynamic evaluation.

A week after the beauty pageant, Blue announced the schedule for the program: The scaled-down proof of concept (POC) airplane, together with a full-scale fuselage mockup, would be presented at the National Business Aviation Association (NBAA) convention in Dallas in the summer of 1984. In the meantime, design work would proceed on the full-scale airplane, with a two-year target for first flight. Not only that: Blue wanted it to have every feature that future airplanes were expected to have, including a three-phase electrical system, carbon composite structure and “glass panel” instruments and avionics. “With all the improvements coming, along with Moore’s Law,” he later said, “I felt we needed to go with the latest and greatest.” (Moore’s Law states that computer processing speeds double every two years.)

Beech engineers, habitually conservative and familiar with the inevitable pitfalls and delays, were aghast. Normally, they would have started with a wind tunnel model. They would not have bothered with a scaled-down POC—that was a novel approach, pioneered by Rutan—but if there was going to be a POC they would expect its design to await wind tunnel results, and once it was built they would carefully evaluate it before proceeding with the final article. As it turned out, Beech engineers did get their wind tunnel model, but Blue’s breakneck timetable telescoped the development process so that what would logically have been successive phases of design and testing instead overlapped one another.

But the Beech team’s feelings were not altogether negative. As project engineer Bill Brown recalled, “In Beech engineering we saw the whole Starship thing as a chance to get something going, as opposed to the usual study it to death and never get a go-ahead.”

Blue had one beef with the design that he had ostensibly chosen on the basis of its looks. Like the VariEze, it had a swept wing but an unswept foreplane. Blue thought the foreplane ought to be swept as well. But sweep would create an aerodynamic problem, compromising the foreplane’s ability to balance the airplane when its flaps were extended for landing.

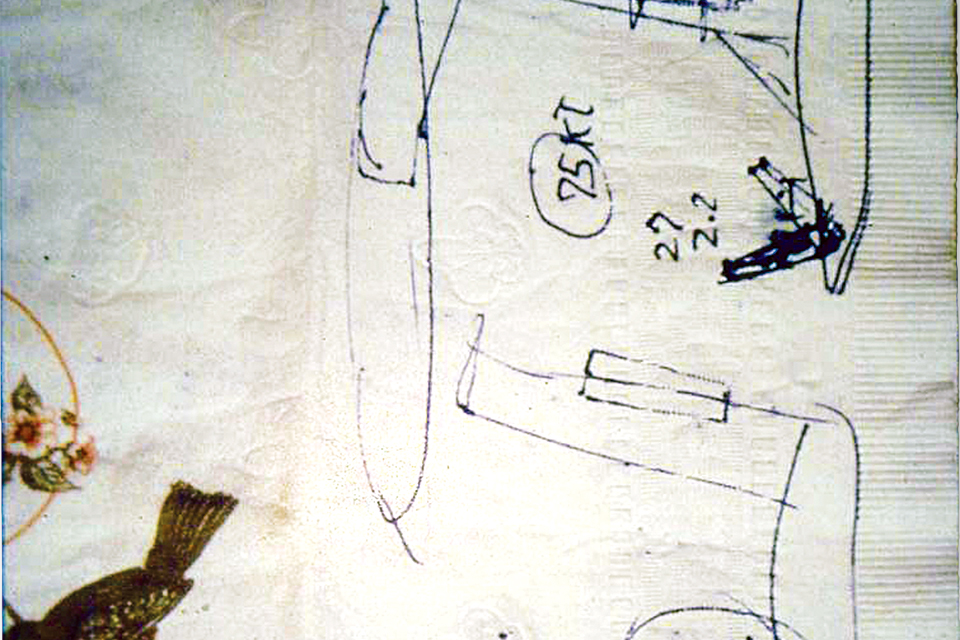

In the summer of 1983, during the annual Experimental Aircraft Association convention, Rutan, Scaled aeronautical engineer Doug Shane and freelance aerodynamicist John Roncz, who had designed airfoil sections for previous Rutan projects, got together over a pitcher of beer at Robbins Restaurant in Oshkosh to discuss the problem. Rutan sketched two solutions on a napkin. In one, the entire foreplane would move fore and aft on rails to balance the flaps. The other was more daring and more elegant: a variable-geometry foreplane that would cruise with jet-like sweepback, but swing forward as the flaps went down for landing. The variable-sweep solution won out, and so, at the expense of some increased weight, cost and complexity, Linden Blue’s aesthetic difficulty with the unswept foreplane was resolved.

Beech, in consultation with Rutan and Roncz, developed the loft lines, which define the precise size and shape of the airplane, and delivered them to Rutan late in 1983. The POC was by far the largest airplane Rutan’s shop had ever built using the foam-and-fiberglass construction techniques that he had developed for his homebuilts, but it rapidly took shape. Shortly before its first flight, however, word came from Beech that wind tunnel analysis had shown that it would not get off the ground. At that time, the Rutan Aircraft Factory was running crude aerodynamics software on an Apple II; Beech had much more sophisticated resources.

“Holy s—!” Rutan recalls thinking. “They’re probably right!”

Rutan’s brother Dick, a former F-100 jock and now test pilot, wasn’t buying it. “Let’s fly it,” he said. And they did. It flew beautifully. The ominous Beech analysis turned out to have suffered from a GIGO error—“garbage in, garbage out”—arising from the misapplication of methods that had been developed for airplanes whose flying surfaces were arranged in the conventional way.

As planned, the POC swooped into the NBAA convention in Dallas in 1984, creating the expected sensation. It brought tears to some eyes. To think that this beautiful vision of the future had come from stodgy, conservative Beech, of all places!

As flight tests with the POC proceeded, the full-scale article was being engineered and tooled. Despite their identical shape, they were entirely different airplanes. The carbon-fiber structure, a pioneering choice that was expected to result in a 15 percent weight savings, had to be designed, tested and certified by the FAA, which had no experience with composite structures. Neither did Beech.

Linden Blue, on the other hand, did have such experience. He had been involved with the Lear Fan, a novel design with two turbines buried in the aft fuselage and geared to a single pusher propeller. The Lear Fan, he would later say, was really a “black metal” airplane; it was built using construction techniques appropriate to aluminum, including rivets, but out of parts made of carbon-epoxy composite. Proper composite construction required a fresh start. Blue was convinced that the right approach for building the fuselage, at the very least, was filament winding, a highly automated but as yet untried approach in which epoxy-soaked carbon fibers are wrapped around a rotating fuselage-shaped mold by a computer-controlled moving spool. Beech engineers, knowing that they were already way out on a limb building a large composite airplane, preferred a simpler and more intuitive method, in which sheets of carbon cloth, pre-impregnated with epoxy, were cut to shape and laid down in molds, then baked under a partial vacuum. The engineers won, and Blue left after a short two-year tenure. “I was unwilling to preside over an airplane that was going to be fundamentally flawed,” he said.

Blue’s legacy, however, remained. As Max Bleck, who became president of Beech in 1987, would later relate, the schedule for certification by the end of 1985 had been exceedingly optimistic. Repeated schedule slippages, extending over years, created the widespread impression of a failing project.

Not that the Starship didn’t have plenty of problems of its own.

The POC uncovered a major aerodynamic issue: If the airplane slowed excessively with the canard in its swept position, as might happen when cruising at very high altitude, the main wing would stall and the nose would pitch up. To the pilot, it would appear to be in level flight, but perplexingly descending at 6,000 feet per minute. The wing could be unstalled by extending the flaps and swinging the foreplane forward—the two actions were interconnected—but the situation was unacceptable in a production airplane.

“Burt had a different safety philosophy than the FAA,” explained Bill Brown. “Burt would restrict the airplane to avoid any potential scenarios; the FAA requires no unsafe scenarios.” Various tricks to prevent the pitch-up were tried. One approach would have been to increase the “washout,” or twist, of the wing, so that its outer panels would remain unstalled. Since they were farther aft, this would result in the airplane pitching down rather than up—the desired behavior. But the wing could not be changed, because, under the compressed schedule, the master plugs—huge aluminum castings machined to the proper shape—had already been made.

Finally, small vertical blades below the leading edge, dubbed “vortilons,” did the trick on the POC. But the solution did not work on the first full-scale prototype, which was ready to fly early in 1986. It was equipped with an ejection seat, just in case. Running out of aerodynamic tricks, engineers were finally obliged to resort to the traditional solution for bad low-speed behavior: an electromechanical “stick pusher” that would sense the impending stall and push the control stick forward, overpowering the pilot.

Stalling behavior was not the only respect in which the full-scale airplane failed to duplicate the characteristics of the POC. It was also much slower—50 knots shy of the predicted airspeed. This was mysterious: It was the same shape, just bigger, and ought to have had about the same drag coefficient.

The usual suspect in such cases is propeller efficiency, that is, the percentage of power put into the props by the engines that actually ends up propelling the airplane. Typically, nose-mounted (“tractor”) propellers achieve 85 percent efficiency, more or less. As Brown recalled aerodynamicist David Bernstorf saying, you could scale up tongue depressors and get 85 percent. In theory a pusher propeller ought to be a little more efficient, in part because its slipstream is not partially blocked by a fuselage or nacelle. But that is true only when the fuselage or nacelle ahead of the pusher propeller is smooth and symmetrical, like a blimp or torpedo. Rotating through the wing’s wake, the Starship’s propeller blades encountered a constantly changing inflow stream. It was impossible to design a blade that was optimal for all conditions.

Another problem was the orientation of the engine nacelles. With engine-out handling and power-related pitch changes in mind, Beech engineers had canted the engines two degrees nose-down and three degrees nose-in. Both cants proved aerodynamically unfavorable; the upward tilt of the engine meant that the propeller plane was misaligned with the wake of the wing, while the pigeon-toed stance of the nacelles created a drag-producing divergent channel between them and the sides of the fuselage. Eventually, with the missing knots proving extremely difficult to find, the nacelles were sawed off and re-installed with cants exactly opposite to the original ones. The airplane immediately picked up 10 knots.

Several knots were lost when smooth “weeping wing” de-icers were replaced with old-fashioned rubber boots. The reason for the change was far from aerodynamic: It was feared that traces of the ice-resistant slime that oozes from the low-drag de-icers might stain the clothes of someone who carelessly brushed past the wing while boarding. Some speed, but not enough, was regained when different engines—a last resort—brought the power up from 1,500 to 2,400 horsepower. Eventually, the Starship hit a wall at 335 knots. That became its official maximum speed; it cruised at around 310.

At the same time that Beech aerodynamicists were fighting a losing battle against drag, structural engineers were in retreat before ever-increasing weight. The carbon composite structure had only a slight effect, because so much of the airplane was made of something else. Eventually, the Starship exceeded the 12,500-pound limit of its intended certification category by 2,400 pounds.

The first production airplane finally reached the market in 1989. To call its reception lukewarm would be kind. Lots of explanations for its commercial failure have been proposed, but the simplest is that it cost as much as a jet and was 100 knots slower. The Starship, as Richard Collins wrote in AOPA Pilot magazine in October 1990, was not only a runway hog, requiring more distance to get airborne than some jets, but was also “over on weight, short on cruise speed, noisy in the cabin, and a bit truck-like to fly.” This from a writer who normally tucked his unflattering opinions away between the lines. Beech advertised in Pilot, however, and so Collins had to find something good to say: “Where the Starship is perfect is in sizzle….I looked down at the shadow streaking across the ground and was struck with the feeling that, finally, after 39 years of flying, I had found a next-generation general aviation airplane.”

Sizzle was not enough; for $4 million, customers wanted some steak as well. Beech built only 50 production Starships. When it could not sell them, it tried leasing them instead. Finally giving up, Raytheon bought back as many as it could and destroyed them. A few are still in private hands; not too surprisingly, human nature being what it is, their owners love them. Raytheon admitted to having spent $350 million on the Starship, though insiders say the amount was more like $1 billion.

Proverbially, success has many fathers, but failure is an orphan. Perhaps it would be more accurate to say that failure is always someone else’s baby. Drew Steketee, a former head of Beech corporate communications, later hinted at the internal frictions that arose after Linden Blue bypassed Beech’s own engineering staff in virtually turning over the Starship’s aerodynamic design to Burt Rutan, and alluded darkly to “detested Raytheon corporate types.” Rutan, who became a Beech vice president for a time and was briefly married to the daughter of one of the old guard executives, blamed the Starship’s faults on decisions made by Beech engineers, who, in turn, pointed out that Rutan had never taken one of his designs through the FAA certification process.

Unfortunately for the hundreds of people who worked on the project, the Starship’s commercial failure eclipsed the fact that they had actually accomplished something quite remarkable. They had created a revolutionary airplane, developed and validated manufacturing and certification procedures for a new method of construction, and created the first glass panel in a general aviation airplane. They had done much of this the old fashioned way, without the help of powerful digital tools. Linden Blue had demanded the almost-impossible, and Beech had almost delivered it. Only someone who has designed, built and certificated an airplane could appreciate how much Beech actually achieved. But commercial failure upstaged technical success. The rest of the world saw the Starship just as a Fortune magazine article, dripping with schadenfreude, did: “It’s a dud,” the author gloated. “A fiasco. A Little Bighorn with wings.”

L.A.-based writer Peter Garrison has designed, built and flown a couple of airplanes of his own, but has never exposed them to the merciless scrutiny of the marketplace. Further reading: Burt Rutan: Aeronautical and Space Legend, by Daniel Alef; and Beechcraft: Staggerwing to Starship, by Edward H. Phillips.

This feature originally appeared in the March 2019 issue of Aviation History. Subscribe here!