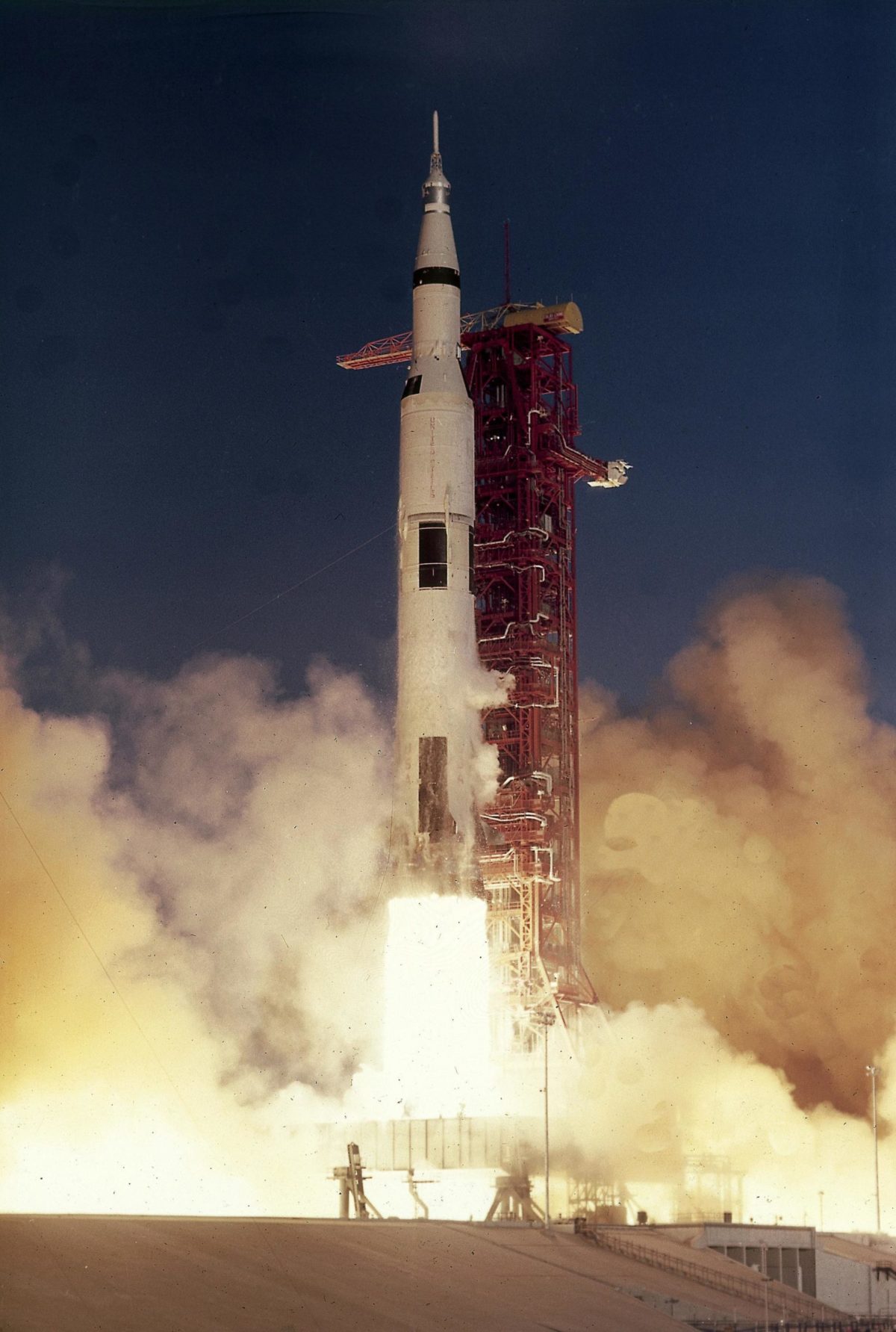

One of the defining images of the 20th century is of Apollo 11 ascending on a pillar of incandescent fire from Pad 39A at Kennedy Space Center on July 16, 1969. Far atop the huge Saturn V launch vehicle, three men began a journey that has been unmatched since the end of the Apollo program. Their flight to the moon took two days, but it was the first 165 seconds that made it all possible. At the very base of the mighty Saturn rocket were five massive engines, each of which produced a little over 1.5 million pounds of thrust. Together, their 7.6 million pounds of thrust lifted that huge 3,000-ton vehicle away from Earth’s gravity and into the boundaries of space itself.

The Rocketdyne F-1 was, quite literally, the driving force that took mankind to the moon. It represented a quantum leap in size and power from anything built before. Prior to the F-1, the largest and most powerful liquid-fueled rocket engine in development was the E-1, with 188,000 pounds of thrust. This was woefully inadequate for the task that lay before NASA in early 1961.

How the F-1 was conceived, designed, built and tested is a saga worthy of the Wright brothers or Charles Lindbergh, but on a far grander scale.

Rocketdyne was founded by North American Aviation with a team of skilled rocket engineers from the U.S. Army’s Redstone Arsenal in Huntsville, Ala. In 1958, the Air Force contracted with Rocketdyne for an engine that would become the F-1. Based in Canoga Park, Calif., the company built and first tested components at its facility in the Santa Susanna Mountains north of Los Angeles.

Jerry Butsko, who joined Rocketdyne right after graduating from the University of Washington, described the tests as impressive.

“You really felt it when that thing went off,” he said with a laugh. Butsko worked on the nozzle, the bell-shaped cone from which the rocket’s force was expelled.

“We called that nozzle ‘King Kong.’ It was huge. During one test, that thing just exploded. Everybody in the entire region heard it.”

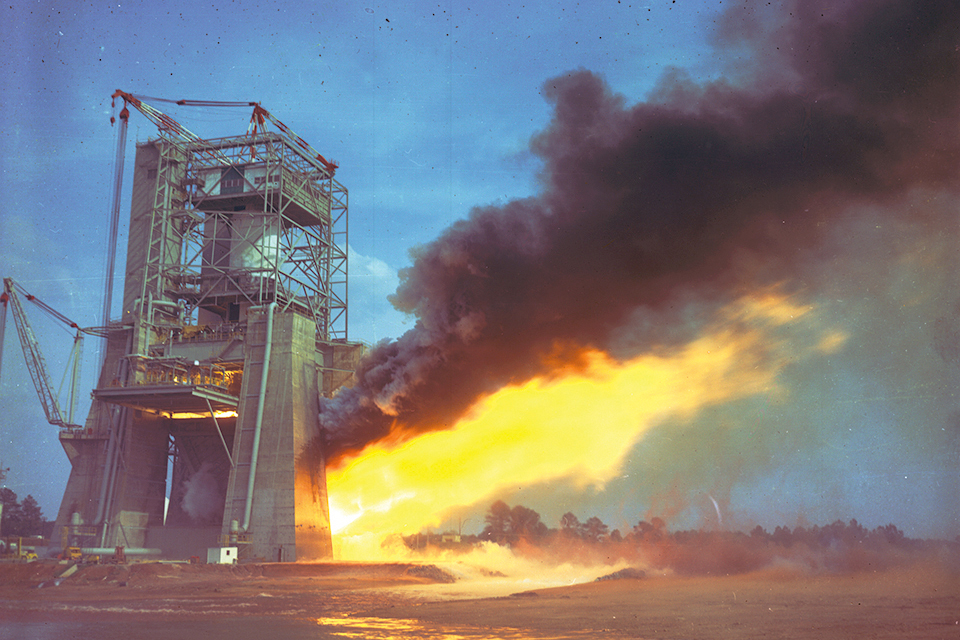

After that, Rocketdyne moved the testing to Edwards Air Force Base in the Mojave Desert, where the company built a massive test stand. The huge structure’s legs were solidly anchored into California bedrock.

The Air Force canceled the project when it became apparent there was no military need for such a huge engine. But in July 1958, President Dwight D. Eisenhower established the National Aeronautics and Space Administration and took the first serious steps toward a moon landing. When John F. Kennedy was inaugurated in January 1960, the lunar program was well into the concept stage.

NASA had chosen lunar orbit rendezvous as the method to reach the moon. The fully loaded Saturn V launch vehicle would weigh in at 6.2 million pounds.

The first stage, known as the S-IC, had to lift this immense burden off the launch pad and take it out over the Atlantic Ocean. Then the second stage, the S-II, would take over and bring the crew closer to orbit. Although it would take 11 minutes from ignition to orbital insertion, those first 165 seconds were the most important. Wernher von Braun’s team at the Marshall Space Flight Center in Huntsville calculated that an engine for the S-IC first stage would need to generate 1.5 million pounds of thrust. The only existing rocket engine capable of such power was the unproven F-1.

In April 1961, Soviet cosmonaut Yuri Gagarin became the first man in space. Then American Alan Shepard made his 15-minute suborbital flight on May 5. The Redstone rocket he rode produced only 78,000 pounds of thrust. Just 20 days later, Kennedy asked Congress to support the national goal of “landing a man on the moon and returning him safely to the earth.”

It was an audacious decision to go with the unproven F-1. Just before Gagarin’s flight, a prototype F-1 combustion chamber was tested and achieved 1.64 million pounds of thrust, proving the design. But this was a very brief test, far from what a production F-1 would have to reliably attain. No one knew for certain if it could be done. Even the Russians, with their proven heavy-lift rockets, had not attempted to construct anything that powerful. Some members of Kennedy’s Science Advisory Committee said the engine was just too big to work.

While the F-1 was a vast leap forward in size, it still used the same basic technology that Rocketdyne had tried and proven on several previous engines. From the Army’s Redstone to the Air Force Atlas and many others, the technology was basically the same. But no one had ever successfully built a rocket with more than a million pounds of thrust.

By mid-1962, the Rocketdyne team was ready for a sustained test of the F-1 combustion chamber. At the Edwards test stand on June 28, they lit the igniters and started the turbopumps.

Then, as the assembled engineers and NASA officials watched, the engine destroyed itself in a quarter of a second.

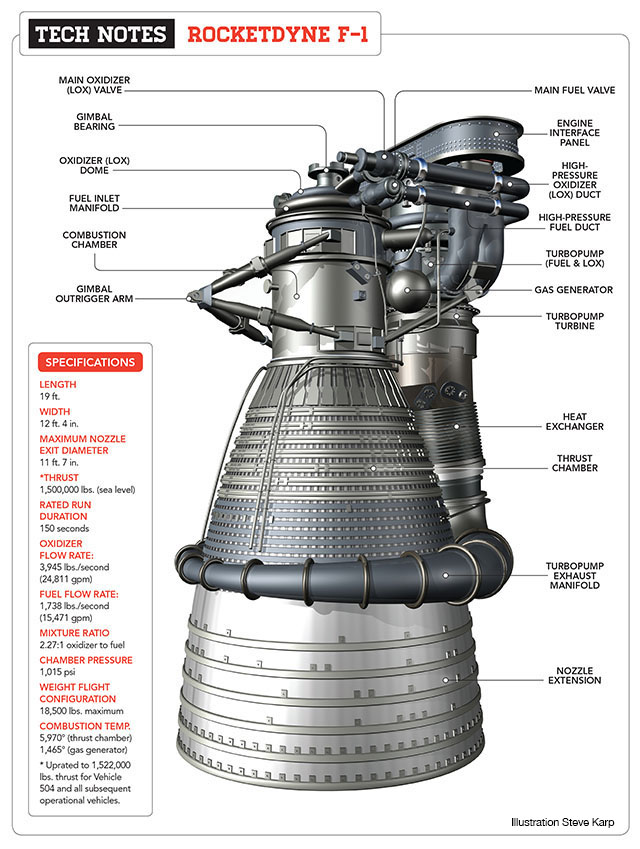

What went wrong? A rocket engine is actually a very simple machine, at least in concept. Turbopumps inject fuel and oxidizer into a combustion chamber in the presence of a flame. The mixture ignites, creating pressure, which becomes thrust by driving upward against the top of the engine as it vents down out the nozzle. If the thrust is greater than the weight of the vehicle, it lifts off. The interior of the combustion chamber is a hollow cylinder with an injector plate near the top. Hundreds of holes are drilled into the plate, through which the two liquids are pumped to combine to form a mixture that is then ignited.

But in order for the engine to work properly, two things must happen exactly right. The fuel and oxidizer must be mixed in the proper proportions, and they must burn smoothly. The F-1, like many other rocket engines before and since, used RP-1 (a form of kerosene) as fuel and liquid oxygen (LOX) as an oxidizer. With nearly every rocket engine built up to that time, if combustion was unstable or the flow uneven, it was usually a simple matter to rectify.

That would not be the case with the F-1. The problem was in scale. The F-1’s combustion chamber was a barrel-shaped cylinder nearly 3 feet in diameter. The injector plate was 4 inches thick and weighed 1,000 pounds. Exactly 6,300 holes, each no larger in diameter than a soda straw, were drilled in the plate, through which the liquids were injected. The holes were arranged in groups of five, with two holes for the RP-1 and three for the LOX. They were designed to combine the streams in two fans at an exact distance from the bottom of the plate, where they would combust. At the moment of ignition, the chamber’s temperature shot up to nearly 6,000 degrees, with pressure soaring from zero to 1,015 pounds per square inch (psi), creating the desired 1.5 million pounds of thrust.

The problem the Rocketdyne engineers faced in June 1962 wasn’t simply a bad part or faulty weld. It involved something that had rarely been an issue with smaller engines: combustion instability. Ideally, the injectors and igniters created a “smooth flame front,” in which the RP-1 and LOX burned at a uniform temperature and pressure under the entire face of the injector plate. But the F-1’s great size made that virtually impossible. If too much LOX was injected on one side of the chamber, it caused the temperature at that point to be far higher than on the other side. This formed a pressure wave that rebounded from one side to the other, creating a “racetrack” effect with the heat and pressure running out of control in milliseconds, often destroying the engine. Virtually anything could trigger a runaway instability, such as a brief fluctuation in the turbopumps or the thermal shock from the sudden temperature increase.

For NASA and Rocketdyne, this was no small problem. It was a major crisis.

At that point, Rocketdyne propulsion engineer Paul Castenholz and Daniel Klute, a mechanical engine researcher, entered the picture. Along with the Marshall Space Flight Center’s Jerry Thompson, a liquid fuel systems specialist, they headed a team of 50 skilled and motivated engineers and technicians to fix the problem. Designated the Combustion Devices Team, they were tasked with making the F-1 reliable. According to Castenholz, the team had the highest priority in the company.

“They got what they needed, who they needed and when they needed it,” he said.

Early on, the team hoped the problem could be fixed without a full redesign of the combustion chamber, something that would set the timetable back months. They worked on adjusting the liquid flow rates, the hydraulics and the angle and pattern of the holes. Each fix was then tested on the Edwards stand, and each time the instability reemerged. The testing had destroyed two engines by the beginning of 1963, but the engineers were still confident they would eventually fix the problem. They all knew that the future of the lunar program — and possibly of NASA and manned spaceflight — hung in the balance.

The most difficult task was to determine what caused the instability, as it proved to be both intermittent and unpredictable.

“There was no consistency,” Thompson said. “It would happen for reasons we never quite understood.” This of course was in an era before sophisticated computer modeling and analysis.

At that point, the team hit upon a radical idea. As Castenholz explained, “We had to be able to initiate instability at our command.” They needed a way to consistently create combustion instability to design a fix that worked every time.

The solution was to put a bomb in the combustion chamber.

During a firing test, they would hang a small, heavily insulated black powder explosive in the chamber under the injector plate. This radical step required some serious brainstorming. Castenholz said they first tried to insert it up the nozzle during firing, but that didn’t work. By placing the explosive in the chamber prior to firing, with an insulated wire so it could be detonated at the desired time, the team was finally able to achieve combustion instability when they wanted it. Far beyond trying to develop an F-1 that would run normally, the Combustion Devices Team was striving to make it run even after a bomb exploded in the chamber. The real challenge was for the engine to quickly reach what was called “dynamic stability,” meaning it would correct itself in 400 milliseconds.

By the spring of 1964, as the Gemini Program was making headlines, Thompson, Castenholz and Klute’s team had accepted that a perfect fix seemed unattainable. For the next 24 months, the team concentrated on the injector plate — the heart of the system. They installed copper baffles to break up the rebounding shock waves. The first ones were thin, and Thompson noted the shock waves bent them over like a tornado had gone through. The next baffles were 2 inches thick at the base and cooled from RP-1 in the injector plates.

“They did help,” Thompson said, “but they failed to stop the instability. We tried every trick we could think up, at least 40 or 50.”

Each time they tested a new idea, it sometimes worked and sometimes didn’t. It got to the point where they were repeating ideas they had already tried weeks earlier.

Months passed without a solid solution. Sometimes the F-1 became unstable after the bomb went off and petulantly refused to settle down, but sometimes it did. Each time, the team was a bit closer to success. In the summer of 1964, the engineers decided to change the angle of the holes in the injector plate so the liquids would impinge slightly farther down in the chamber. This decreased efficiency by a few percent, but the instability also became less frequent. More adjustments were made until the incidents of instability decreased and at last ceased entirely. In each test, the bomb detonated, the pressure shot up and then the combustion stabilized in 100 milliseconds.

That was the turning point for Rocketdyne. On April 16, 1965, nearly three years after the original engine prototype had been tested, five F-1s were mounted on the Huntsville test stand and fired together for the first time. A searing yellow-white column of flame shook the ground like a sustained earthquake. All the engines worked perfectly, generating 7.5 million pounds of thrust for 6.5 seconds. Although the team didn’t yet know it, they had finally fixed the problem. The F-1 never failed to work perfectly from then on. The November 9, 1967, flight of the unmanned Apollo 4 Saturn V was a success.

Thirteen months later, the F-1 made history.

On the morning of December 21, 1968, three astronauts sat in the Apollo 8 Command Module atop Saturn V SA-503. Frank Borman, Jim Lovell and Bill Anders were about to leave Earth to become the first men ever to reach the moon. The 363-foot-tall Saturn V stood on the concrete pad, nestled in the steel embrace of the 500-foot red launch tower.

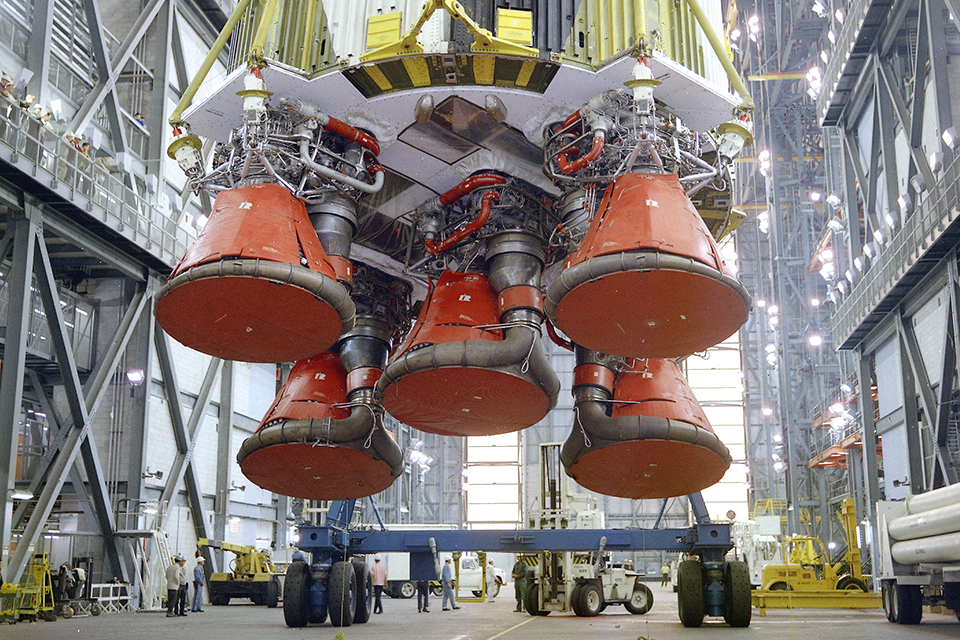

The Saturn’s S-IC first stage was a giant, 33-foot-diameter cylinder containing two propellant tanks and five F-1 engines. The turbopumps had to reliably force huge quantities of fuel and oxidizer into the five combustion chambers. The five new F-1 engines waited like restless stallions, ready to devour the 534,000 gallons of RP-1 and LOX in the tanks. Driven by a 55,000-hp turbine, the fuel would be pumped at 15,471 gallons per minute and the LOX at 24,811 gallons per minute, or five tons of RP-1 and 10 tons of oxidizer every second—enough to fill a 25-foot swimming pool in 27 seconds. The structure on which the engines were mounted weighed 21 tons and was designed to distribute the 3,750 tons of thrust against the rocket’s base.

Just before 12:51 p.m., at T-minus 8.9 seconds, the launch sequence began with the lighting of four igniters in each engine, burning the fuel-rich mixture in the turbine-powering gas generators. Five huge clouds of black smoke and orange flames from the gas generator erupted from the engine nozzles and engulfed the base of the rocket. LOX sprayed into the main combustion chambers, where it combined with an explosive charge of igniter fuel, touching off an inferno at T-minus 6.4 seconds. As pressure in the combustion chambers reached 20 psi, the main fuel valves opened. The fuel first ran through a web of tubing in and around the combustion chamber walls to help cool it during firing.

The turbopumps spooled up to full power. In each engine, a ton of RP-1 and two tons of LOX were forced through the 6,300 holes so painstakingly drilled into the injector plates. As the mixture burned, pressure reached 1,015 psi, and the roaring inferno shot from the 12-foot-wide exhaust nozzles into the wide flame trench beneath the launch pad. An incandescent fireball erupted from the base of the rocket. The five engines were timed to reach full power at slightly staggered intervals to prevent a single massive shock wave from slamming into the rocket. By T-minus 0.0, the combined thrust had reached 7.5 million pounds, and four huge hold-down arms released the straining monster while the upper five umbilical arms connecting the rocket to the tower swung away.

In a third of a second, the Saturn V was free.

The ponderous rocket, as long and heavy as a World War II destroyer, began to climb. The roar of a Saturn V’s engines entering main stage was, next to a nuclear detonation, the loudest man-made sound on Earth. Three miles away at the public viewing areas, the sound first came through the ground like an approaching earthquake and then hammered spectators’ ears like a volcanic eruption. Slowly at first, as if reluctant to leave the Earth, but then gradually gaining speed, the Saturn ascended on five blinding white pillars of flame. As it cleared the tower, the sound roared and rebounded for miles. It was several hundred feet in the air before the searing column of flame cleared the launch pad and the rocket started to head out over the Atlantic.

Still the mighty F-1s continued to burn perfectly, gulping 15 tons of fuel and LOX every second, until the Saturn was streaking through the azure sky at 5,400 mph at an altitude of 36 nautical miles and 50 miles downrange. At 12:53:30, 150 seconds after ignition, the F-1s shut down. They had done their job. With a bang of pyrotechnic charges, the S-IC first stage was jettisoned and fell away into the ocean, carrying the F-1s to a watery grave. The S-II second stage’s five J-2 engines ignited for their role in taking Apollo 8 into space.

While the people at Kennedy Space Center and Mission Control in Houston, Texas, cheered, the Apollo 8 crew began their historic flight to another world. Forgotten in the excitement was the job done by the exquisitely designed machine that made it possible. Yet for the men and women of Rocketdyne who designed, built and perfected the F-1 through all those frustrating months of toil and sweat, their triumph had finally come.

It is not a stretch to say that without the Rocketdyne F-1, there would likely be no human footprints on lunar soil.

Mark Carlson is the author of two books on aviation history and an avid fan of NASA’s golden age. Recommended reading: Apollo: The Race to the Moon, by Charles Murray and Catherine Bly Cox; The Saturn V F-1 Engine: Powering Apollo Into History, by Anthony Young; and Saturn V Flight Manual, a NASA publication.

This feature originally appeared in the January 2017 issue of Aviation History.