A father-and-son team spent eight years piecing together a ground-looped Stinson L-5E.

“It was a great day. Just a beautiful morning. It had rained earlier but cleared by 10:30. No crosswind.”That’s how Marty Stickford Jr. matter-of-factly described the conditions on September 28, 2012, for first flight of his fully restored World War II– vintage Stinson L-5E Sentinel at the tiny airport in Benson, Arizona. Marty’s wife, Marie, admitted to being a little more emotional about that first flight, the culmination of more than eight years of work by Marty and his father, Martin Sr.: “I cried,” she said.

First to take the controls that morning was Eric Seabase, a certified FAA mechanic and inspector. As he slid into the pilot’s seat, he turned to Marty Jr. and asked, “Don’t you want to be on board for the first flight?” pointing to the seat behind him. Stickford, who said he was “bit nervous,” left it to Seabase, an experienced tail-dragger pilot, to handle that initial takeoff and landing. “When we lifted off it was fantastic!” Stickford recounted. “That was the only word I could think of at the time.”

Back in 2004 Marty and his dad had contacted Jim Gray of the Sentinel Owners and Pilots Association in Phoenix, Ariz., about an L-5 for sale by a club member. The airplane had been in a ground-loop accident that severely damaged its left wing, bent the firewall and motor mount, and dented the left cowling. The owner had started repairing some of the damage, but it was obvious that the airframe, mainly the wings, would need considerable work. After some debate, the father-and-son team bought the mangled Sentinel, which was loaded onto a trailer and transported to Benson’s airport.

The first job was to remove the airframe fabric. Once they did that, the Stickfords found the tubular fuselage was in good condition, but the wings were in need of major rebuilding. “The break in the spar on the left wing was very bad, almost unrepairable,” said the elder Stickford. “We had to splice in all new wood and replace the bent aluminum slat on that wing.” He added that if there had been a few inches’ more damage to the spar, the whole project would have been in jeopardy. They decided the right wing would also have to be rebuilt; most of the ribs were in good condition, but the leading and trailing edge pieces had been damaged.

According to Martin Sr., shaping the wood for the wing leading edges was among the most difficult, time-consuming tasks they faced.“We soaked 0.63 sheets of mahogany in troughs of water for about a week, applied heat and then carefully worked them into a tight curved shape,” he explained.

Constructing and shaping the wingtips proved to be even more daunting. “We used eight layers of 1/8th-inch-thick strips of rotary-cut poplar for the tips,” the senior Stickford said. The poplar strips, the same wood used on the original aircraft, were steamed into shape, clamped into a form and, when dry, laminated together, then carved into shape. After two years of work, the skeleton of the finished wings gave an impression of finely crafted, varnished furniture.

Next the team turned to the fuselage, where the oleos were rebuilt and the tail wheel assembly was refurbished. Since the chrome tubular fuselage framing was undamaged, it needed only cleaning and painting. In the cockpit, the instruments were cleaned, rebuilt and fitted with new wiring. A new panel was fabricated from sheet aluminum and painted nonreflective black. A set of modern radios was installed, along with new wiring for the electrical system.

The 6-cylinder, 190-hp Lycoming O-435 engine was especially designed and manufactured for the L-5. The Stickfords’ power plant had low hours, but Seabase checked it out and brought it up to modern-day specifications. “During WWII this engine used 78- octane gas,” Marty Jr. said with a laugh, adding that the L-5’s engine initially did not “like” today’s 100-octane aviation fuel.

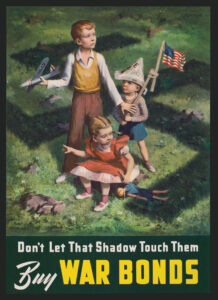

Nicknamed the “Flying Jeep,” the unarmed L-5 was classed as a liaison plane by U.S. and British forces during the war. A total of 3,590 were produced between 1942 and 1945. Early models, which could be easily identified due to their slim aft fuselage and wraparound rear window, served as artillery spotters and also did short-range reconnaissance, courier service and general utility work.

L-5s from the B through G variants, fitted with a large door aft of the passenger cabin, were used as air ambulances. About 750 L-5Es were manufactured as short-takeoff-and-landing models, fitted with “drooping” ailerons that could be manually lowered by the pilot, enabling the aircraft to operate from short, unimproved fields. Some were also fitted with larger tires that enhanced their STOL capabilities.

The Stickfords’ L-5E was built in Wayne, Mich., and accepted by the U.S. Army Air Forces on March 27, 1945. Records show the L-5, serial no. 44-17504, was sent to Detroit, then crated and shipped to New York, then to England. Since the war in Europe was virtually over by the time it arrived, this Sentinel apparently never saw combat, but it did see duty with the U.S. Constabulary Forces.

After serving with Army ground forces in 1947 and the 7th Field Artillery Battalion in 1948, the Sentinel was assigned to a Civil Air Patrol squadron at Erding Air Force Base, near Munich, Germany. It returned to the U.S. in 1952 and was assigned to the Air Materiel Command at Newark, N.J., and the 2847th Transportation Center Wing. Later in the 1950s it was dispatched to the West Coast with the Oregon Wing of the Civil Air Patrol and the 337th Fighter Group at McChord Air Force Base near Tacoma, Wash. Beginning in 1956, the L-5 had a series of civilian owners, and spent time at a museum in Anchorage, Alaska. After that museum closed, the L-5 went to the Planes of Fame Museum in Chino, Calif. It was last flown in 2002 by a civilian owner, who ground-looped it at Spanish Fork, Utah.

When retired Air Force Major Bob Elson, a friend of the Stickfords’, saw the Sentinel being restored in June 2011, it brought back wartime memories. Elson, who flew various military aircraft in India with the 411th Air Service Command in 1945, recalled that he had been on duty near Calcutta on March 21 when a call came in requesting an emergency medical evacuation of a serviceman with acute appendicitis from Char Chapli Island, in the Bay of Bengal. Elson and a doctor volunteered to fly in an L-5E to the remote isle that night and pick up the soldier. The only place to put down was on the beach, and the landing and takeoff coincided with high tide, making the trip extremely dangerous. Elson and the doctor completed their mission, and the soldier recovered after surgery.

In a nod to the L-5’s history as an air ambulance, the Stickfords commissioned artist Bruce Crandall to paint a caricature of a nurse against a red-cross background on the Sentinel’s cowling. Surrounding the nose art is the legend “House Call.”

Late in the summer of 2011, the Stickfords fired up the engine for the first time in almost a decade. They discovered, and fixed, a few oil leaks. Taxi testing subsequently proved the aircraft handled well on the ground.

Final projects included repairing the fabric around the rear fuselage and installing a new windshield. The wings were covered with polyester aircraft fabric, and the entire aircraft was painted military dark green. When the team discovered a leaky gas tank in one of the wings, they had to remove the fabric and repair the leak before restoring the covering. “That leak was just one of the little problems that came up and set us back time and money,” the younger Stickford said. After eight years of work, done mostly on weekends and holidays, they finished the job with the purchase, restoration and installation of an original Sensenich propeller.

The restored L-5’s first flight on September 28 lasted just 20 minutes. But looking back, Marty Jr. described it as “the most fantastic time I can remember.”

Originally published in the March 2013 issue of Aviation History. To subscribe, click here.